Valve with Competitive Price from Valve Manufacturer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Gate Valve Description:

A gate valve, also known as a sluice valve, is a valve that opens by lifting a round or rectangular gate/wedge out of the path of the fluid. The distinct feature of a gate valve is the sealing surfaces between the gate and seats are planar, so gate valves are often used when a straight-line flow of fluid and minimum restriction is desired. The gate faces can form a wedge shape or they can be parallel. Gate valves are primarily used to permit or prevent the flow of liquids, but typical gate valves shouldn't be used for regulating flow, unless they are specifically designed for that purpose. Because of their ability to cut through liquids, gate valves are often used in the petroleum industry. For extremely thick fluids, a specialty valve often known as a knife valve is used to cut through the liquid. On opening the gate valve, the flow path is enlarged in a highly nonlinear manner with respect to percent of opening. This means that flow rate does not change evenly with stem travel. Also, a partially open gate disk tends to vibrate from the fluid flow. Most of the flow change occurs near shutoff with a relatively high fluid velocity causing disk and seat wear and eventual leakage if used to regulate flow. Typical gate valves are designed to be fully opened or closed.When fully open, the typical gate valve has no obstruction in the flow path, resulting in very low friction loss.

2. Main Features of the Gate Valve:

• Valve body cavity using non-toxic epoxy resin,both inside and outside flashboard completely is coated with rubber

• Free of water pollution

• High manufacturing accuracy

• High strength

• Environmental protection and energy saving

• Good visual effect

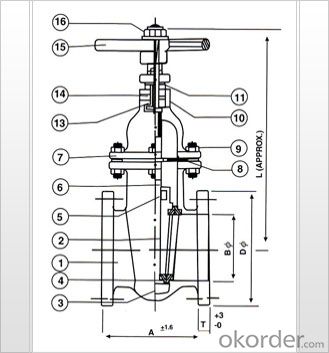

3. Images

4. Gate valve Specification

5.FAQ

1. What's are the characteristics of gate valve?

The distinct feature of a gate valve is the sealing surfaces between the gate and seats are planar, so gate valves are often used when a straight-line flow of fluid and minimum restriction is desired. The gate faces can form a wedge shape or they can be parallel.

2. What is the work principle of gate valve ?

The gate faces can form a wedge shape or they can be parallel. Gate valves are primarily used to permit or prevent the flow of liquids, but typical gate valves shouldn't be used for regulating flow, unless they are specifically designed for that purpose. Because of their ability to cut through liquids, gate valves are often used in the petroleum industry.

3. What is the structure?

Bonnets provide leakproof closure for the valve body. Gate valves may have a screw-in, union, or bolted bonnet. Screw-in bonnet is the simplest, offering a durable, pressure-tight seal. Union bonnet is suitable for applications requiring frequent inspection and cleaning. It also gives the body added strength. Bolted bonnet is used for larger valves and higher pressure applications.

- Q: What does LBC mean in a valve?

- LB and 800 are together. 800LB means 800 pounds of stress, and P should be PRESSURE.

- Q: What do the Z, J, H and D represent in the valve type?

- Valve type code Z, J, L, Q, D, G, X, H, A, Y, S, respectively:Gate valve, globe valve, throttle valve, ball valve, butterfly valve, diaphragm valve, plug valve, check valve, safety valve, pressure reducing valve and steam trapThe connecting codes for valves are 1, 2, 4, 6 and 7, respectively:1, internal thread, 2, external thread, 4, flange, 6, welding,

- Q: I would like to ask how the valve entry, for a new pair, really difficult, what cutaway view, there are other, just contact the valve less than a week, and sometimes it is really difficult to understand. Forget the experienced teacher can be generous with your criticism to later, indebted forever, learn the valve Comrades some help.In a company CAD to relatives as soon as possible to a company, and then slowly improve, I do not know what is the request of the novice, and how to start as soon as possible, I am learning routine is: give me a set of valve design drawings, and then I paint it on, do not understand the structure and workshop look. I wonder if you have any good learning methods that can be referred to and supplemented by younger brother

- Valve range can be very wide, each company to do valve products are not the same;According to the company's production capacity and technology,Valve parameters to:1, valve spool material,2, connection mode (thread, welding, flange, clamp, socket welding, fast loading, etc.),3 caliber,4, medium (water, steam, oil, gas, liquid, etc.),5, temperature (medium temperature, environmental temperature),6, pressure (MPa, LB, K, etc.),7, configuration (executor and its accessories);A lot of valve requirements and this almost. Can also be selected according to the ideal valve function of customers.Switching type:Ball valve, butterfly valve, globe valve, gate valve, needle valve, etc.Regulatory type:Pneumatic valve, electric valve (adjustable type can be divided into: regulating temperature, regulating pressure, regulating flow), and so on

- Q: What is the main function of the valve?

- Acting on switch control, flow regulation, remote control, etc.

- Q: Valve category can fill the trunk door, branch valve Mody?

- Each of these types of valves have very different varieties, such as the valve can be divided into: self sealing valve, knife gate valve, gate valve, cryogenic insulation jacket valve, seal valve, vacuum valve, flexible valve seat seal, valve, gate valve, signal buried forged steel gate, cast iron gate valve and so on.

- Q: Chinese valve and a valve which is better?

- Look what valve you use, ah, these two can be ah!

- Q: How to check if the gas valve is open?

- The valve handle and pipe as "one" word proved to come, as "ten" word is off. Another simple way is to turn clockwise and turn counterclockwise..Chasing the answerThe valve handle and pipe as "one" word proved to come, as "ten" word is off. Another simple way is to turn clockwise and turn counterclockwise..The valve handle and pipe as "one" word proved to come, as "ten" word is off. Another simple way is to turn clockwise and turn counterclockwise..The valve handle and pipe as "one" word proved to come, as "ten" word is off. Another simple way is to turn clockwise and turn counterclockwise..

- Q: What do you mean by the 16 bit coding of the valve type?

- What kind of coding do you mean? Valve type? Stress? Do you have these?Profit ZF43Y-250C-DN50.. Do you mean this one? ZF43Y valve type. Flat gate valve250C. Refers to the 250 pressure, C is carbon steel, DN50 refers to the caliber of the valve specificationsI hope you mean this one

- Q: What are mine valves?

- You want to see what works on the use of what media, in the choice of what type of valve is more appropriate. Shanghai HuquanValve manufacturers, veteran enterprises, trustworthy.

- Q: How are the types of valves classified?

- In addition to the cylinder or hydraulic cylinder piston to drive, but also the use of pneumatic film driven, because of its small stroke and driving force, it is mainly used for regulating valves.Manual valveThe manual valve is the most basic way of driving the valve. The utility model comprises a hand wheel, a handle or a plate hand, and is driven directly and driven by a transmission mechanism two kinds. When the starting torque of the valve is large, it can be driven by gear or worm gear to achieve the purpose of omitting. Gear drive, spur gear drive and bevel gear drive. Gear reduction ratio is small, suitable for gate valve and stop valve, worm gear drive is relatively slow, suitable for cock flashing, ball valve and butterfly valve

Send your message to us

Valve with Competitive Price from Valve Manufacturer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords