Three Way Ball Valve For Water

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

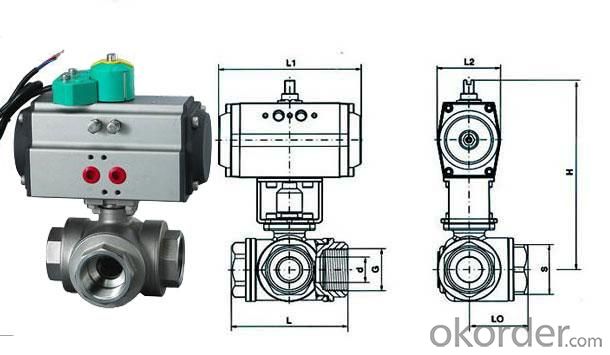

Quick Details of Three Way Ball Valve For Water

Standard or Nonstandard: | Standard | Structure: | Ball | Pressure: | Medium Pressure,150LB~3000LB |

Power: | Pneumatic | Material: | Stainless Steel | Temperature of Media: | High Temperature |

Media: | Water | Port Size: | DN80/3" | Place of Origin: | China |

Model Number: | Q44/5F/H-150LB | Brand Name: | YJ | Product: | Three Way Ball Valve |

Appearance: | Smooth and polishing treatment | Paint: | Resist High Temperature Paint | End: | Flanged/THD |

Certificate: | TS,API 6D | Design Standard: | GB,API,DIN,EN,ISO | Operation: | Pneumatic |

Packaging & Delivery of Three Way Ball Valve For Water

Packaging Detail: | Poly bag then carton then wooden case. |

Delivery Detail: | Depend on the order(quantity and detail of Packing) |

Specifications of Three Way Ball Valve For Water

1.Connection: Flanged

2.Appearance: mirror polished surface

3.Certificate: API 6D

4.Body:CF8M

Usage of Three Way Ball Valve For Water

Pressure class: 150LB -2000LB

Temperature: -268°C--649°C

CF8M structure body.

Suitable medium: water, oil, gas.

Body material: CF8/1.4308,CF8M/1.4408.

Seat: PTFE.PEEK.

Operation: manual control, gear operated, motor actuated.

Design Standard: API 600/6D

Flanged Standard: ASME B16.5

Butt welded Standard: AEME B16.25

Face to Face Standard: ASME B16.10

Inspection and testing Standard: API 598

- Q: What do the Z, J, H and D represent in the valve type?

- 7, pairs of clipsThe transmission modes of valves are code 9, 6 and 3 respectively:9, electric, 6, pneumatic, 3, turbo wormBody material code Z, K, Q, T, C, P, R, V, respectively:Grey cast iron, malleable cast iron, ductile iron, copper and alloy, carbon steel, stainless steel, chrome nickel chromium nickel molybdenum stainless steel, chromium molybdenum vanadium steelSeat seal or lining code R, T, X, S, N, F, H, Y, J, M, W, respectively

- Q: What is the difference between valve j941H-40 and j41H-40?

- Valve design manual showsJ- stop valve9- electric4- connection means flange connection1- through typeH- sealing surface is alloy40- operating pressure is 4.0Mpa (or 40 kg)According to the comparison, we can see that the difference is that one drive mode is electric, one is transmission mode, and the other is manual. What do not understand, you can ask me directly. Two hundred and fourteen million two hundred and seventy-seven thousand eight hundred and fifty-one

- Q: Which industries need valves?

- 3., the other side of energy development is energy conservation, so from the perspective of energy conservation, it is necessary to develop steam traps, and to sub critical and supercritical high parameter development;4., the construction of power stations to large-scale development, so the use of large diameter and high pressure safety valve and relief valve, but also need to quickly open and close the valve;5., for the needs of complete sets of projects, the supply of valves from a single species to more varieties and specifications. The valve required for an engineering project is growing with the full availability of a valve manufacturer.In the next few years, the overall trend in demand for the valve for the upward trend, the valve of this large volume of industrial supplies, its demand in steady growth. Among them, the demand for a larger number of valves in turn are: ball valve (15.5%), cut-off valve (12.9%), safety valve (12.5%), gate valve (12.5%), butterfly valve (10.6%), regulating valve (8%) and check valve (6.1%).

- Q: How to identify the good or bad of the valve, without pressure test and instrument?

- First, the appearance, two according to the standard to see flange thickness, outer circle, wall thickness and other dimensions are standard, 3 see details.

- Q: What does 1/2 mean in valve specification?

- 1/2 is American Standard, said 1/2. Equivalent to GB DN15, nominal diameter 15mm, indicating that the diameter of the pipe is 15mm. In the plumbing industry, it's called 4 points.Valve specifications in common use:Say: American Standard - GB4 points - 1/2 - DN156 points - 3/4 - DN201 inches - 1 - DN251 inches 2 - 1 and 1/4 - DN321 and a half - 1 and 1/2 - DN402 inches - 2 - DN50

- Q: In the decoration, I do not know where to get the valve, what kind of products should be bought?It is hard to fit the valve in the water inlet of the house. If not, can you? Will it have any effect on future use?

- In fact, do not worry about this, decoration master need to use when you will list. In fact, the gas pipeline with copper ball valve, toilet faucet and angle valve, heating and water heater with angle valve, washing machine faucet.Inlet pipe, developers generally only one master valve. If you can, in the kitchen, toilet, these commonly used water where the water inlet valve is also installed, if the pipeline is out of question, you can turn off, do not turn off the main valve. Does not affect other places water, also easy to overhaul, hoped can help you.

- Q: Where is it installed, what is the role, what is the material, and are there other alternatives instead of this effect?

- Mainly from the role of sealing, to prevent leakage of the valve conveying medium, stuffing commonly used PTFE, graphite, asbestos packing three.

- Q: There is a rectangular hole in the valve core, which the heating company repairman gives to the bolt. Rest assured, I do not want to heating, but my indoor temperature is low, I suspect that the repairman mischief, deliberately give me lower temperature

- The heating valve refers only to a radiator system accessories, is a type of valve, the valve commonly used heating system on the market is mainly divided into: gate valve, ball valve, safety valve, balance valve, globe valve, regulator valve, relief valve, pneumatic control valve.

- Q: How do you calculate the flow of the valve?

- Valve flow calculation value is very vague, pipe pressure, back pressure, medium viscosity, medium temperature, valve structure, and so on, will affect the calculated value.

- Q: What's the advantage of using three way valves?

- Three way valve generally has a cut-off, regulation, diversion, and prevent counter flow, voltage regulation and overflow and other benefits, because of its benefits more, so the use of the three valve is extremely extensive, in the valve industry is also very important.

1. Manufacturer Overview

| Location | Liaoning, China |

| Year Established | 2007 |

| Annual Output Value | Above US$ 0.8 Million |

| Main Markets | Mid East, Africa, Europe |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 20% |

| No.of Employees in Trade Department | 128 People |

| Language Spoken: | English; Chinese; Spain; Alabic |

| b) Factory Information | |

| Factory Size: | Above 4,000 square meters |

| No. of Production Lines | 2 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Three Way Ball Valve For Water

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords