Valve with Competitive Price from Valve Manufacturer on Sale in the World

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Gate Valve Description:

A gate valve, also known as a sluice valve, is a valve that opens by lifting a round or rectangular gate/wedge out of the path of the fluid. The distinct feature of a gate valve is the sealing surfaces between the gate and seats are planar, so gate valves are often used when a straight-line flow of fluid and minimum restriction is desired. The gate faces can form a wedge shape or they can be parallel. Gate valves are primarily used to permit or prevent the flow of liquids, but typical gate valves shouldn't be used for regulating flow, unless they are specifically designed for that purpose. Because of their ability to cut through liquids, gate valves are often used in the petroleum industry. For extremely thick fluids, a specialty valve often known as a knife valve is used to cut through the liquid. On opening the gate valve, the flow path is enlarged in a highly nonlinear manner with respect to percent of opening. This means that flow rate does not change evenly with stem travel. Also, a partially open gate disk tends to vibrate from the fluid flow. Most of the flow change occurs near shutoff with a relatively high fluid velocity causing disk and seat wear and eventual leakage if used to regulate flow. Typical gate valves are designed to be fully opened or closed.When fully open, the typical gate valve has no obstruction in the flow path, resulting in very low friction loss.

2. Main Features of the Gate Valve:

• Valve body cavity using non-toxic epoxy resin,both inside and outside flashboard completely is coated with rubber

• Free of water pollution

• High manufacturing accuracy

• High strength

• Environmental protection and energy saving

• Good visual effect

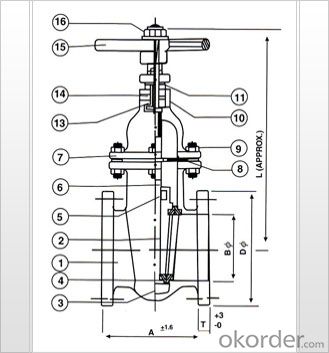

3. Images

4. Gate valve Specification

5.FAQ

1. What's are the characteristics of gate valve?

The distinct feature of a gate valve is the sealing surfaces between the gate and seats are planar, so gate valves are often used when a straight-line flow of fluid and minimum restriction is desired. The gate faces can form a wedge shape or they can be parallel.

2. What is the work principle of gate valve ?

The gate faces can form a wedge shape or they can be parallel. Gate valves are primarily used to permit or prevent the flow of liquids, but typical gate valves shouldn't be used for regulating flow, unless they are specifically designed for that purpose. Because of their ability to cut through liquids, gate valves are often used in the petroleum industry.

3. What is the structure?

Bonnets provide leakproof closure for the valve body. Gate valves may have a screw-in, union, or bolted bonnet. Screw-in bonnet is the simplest, offering a durable, pressure-tight seal. Union bonnet is suitable for applications requiring frequent inspection and cleaning. It also gives the body added strength. Bolted bonnet is used for larger valves and higher pressure applications.

- Q: What does LBC mean in a valve?

- LB and 800 are together. 800LB means 800 pounds of stress, and P should be PRESSURE.

- Q: What is the normal temperature on the valve?

- 3. classification by operating temperature(1): ultra-low temperature valve for medium temperature of t< DEG C; 101 valve.(2): used for medium temperature valve operating temperature 101 C = t = 29 C valve.(3) at room temperature for medium temperature valve: the valve 29 <t<120 DEG C.(4) the temperature valve for medium temperature 120 = t = 425 DEG C valve(5) high temperature valve: valve used for medium temperature t>425 degrees celsius.If it helps, see it

- Q: What are the valves at home?

- Valve used in the family is commonly used, the following are several:On the water pipe are: total table of the ball valve (32mm), in charge of the (25mm), as well as for the toilet, washbasin, water heater angle valve (20mm).Other commonly used gas pipelines, valves, pressure reducing valves and the like.

- Q: such as gate valve, three way plug valve

- The lower part of the pressure gauge installed water pipe, there are water, avoid high temperature, medium pressure gauge contact directly cause damage, so regular cleaning, in order to avoid congestion, three way plug function is used for flushing, please see "how to operate them.".

- Q: Is the heat jacketed valve fitted with flanged flanges?

- Insulation valve is the standard valve, just in order to ensure the link bolt flange to super space, usually a large ball than normal level, such as the use of the path is DN80 flange, flange is DN100, so is the standard, but the size of flange connecting with other valves are not the same.

- Q: What do O and S mean on the valve?

- Generally used in process valves, operating conditions required to open and close, especially in the case of pneumatic actuators installed, the loss of power and gas supply valve when the state

- Q: How to check if the gas valve is open?

- The gas valve has a handle, and the handle is parallel to the pipe and is opened, and the vertical is closed. If there is no handle, there is a rectangular main handle on the valve, the principle is the same as above.

- Q: Representation of several types of valves

- Valve type:Z gate valveJ stop valveL throttling valveQ ball valveD butterfly valveH check valve and bottom valveG diaphragm valveA safety valveT regulating valveX plug valveY pressure reducing valveS trapDZ solenoid valveO electromagnetic motionDrive mode:1. electromagnetic and hydraulic action2., electricity, a liquid3. worm gear4. the spur gear rotates5. bevel gear rotation6. pneumatic7. fluid movement8. air and one liquid movement9. electricOther hand wheel, handle, board hand, no performanceSide mode;1. internal thread2. external thread3. flanges (for double spring relief valves)4. flanges5. flanges (for lever type, safety door, single spring safety door)6. welding7. pairs of clips8. clamps9. card sleeveIllustrated cover or lining:T copper alloyH alloy steelB tin based shaft (bearing alloy)Y cemented carbideX rubberJ hard rubberSA PTFESB poly three fluoro ethyleneSC polyvinyl fluorideSD phenolic plasticsSN nylonValve body material:Z grey castings (usually not shown)X malleable ironQ nodular cast ironT copper alloyB lead alloyII chromium molybdenum alloy steelL chrome alloyP chromium nickel steelV (II) chromium molybdenum vanadium alloy steelR cr.ni.mo.ti steelF fluoroplasticP leather (Shen Penggang)S plasticD nitrided steelCJ lining adhesiveTC magnetic boringCS lined plasticCQ lined with leadW sealing ring is machined from valve body, C carbon steel (generally not shown)G ferrosilicon

- Q: Why is the valve on the pipeline not the same size as the pipe, and how much of a crude pipe can be given? Thank youI'm sorry, I didn't make it clear that when doing pipe work in the factory, for example, 60 of the pipe, and in this pipeline to install the valve to choose DN50, and so on.

- The valves on the pipe should be of the same size, which saves costs and reduces head loss.

- Q: What's the difference between a valve and a valve?

- The correct unit should be called "group". A set of threaded valves include valves, live connections, and short tubes. A set of flanged valves consist of a pair of flanges (including bolts, gaskets, rubber pads), and short tubes".

Send your message to us

Valve with Competitive Price from Valve Manufacturer on Sale in the World

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords