Valve with Competitive Price from Valve Manufacturer in the World

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Gate Valve Description:

A gate valve, also known as a sluice valve, is a valve that opens by lifting a round or rectangular gate/wedge out of the path of the fluid. The distinct feature of a gate valve is the sealing surfaces between the gate and seats are planar, so gate valves are often used when a straight-line flow of fluid and minimum restriction is desired. The gate faces can form a wedge shape or they can be parallel. Gate valves are primarily used to permit or prevent the flow of liquids, but typical gate valves shouldn't be used for regulating flow, unless they are specifically designed for that purpose. Because of their ability to cut through liquids, gate valves are often used in the petroleum industry. For extremely thick fluids, a specialty valve often known as a knife valve is used to cut through the liquid. On opening the gate valve, the flow path is enlarged in a highly nonlinear manner with respect to percent of opening. This means that flow rate does not change evenly with stem travel. Also, a partially open gate disk tends to vibrate from the fluid flow. Most of the flow change occurs near shutoff with a relatively high fluid velocity causing disk and seat wear and eventual leakage if used to regulate flow. Typical gate valves are designed to be fully opened or closed.When fully open, the typical gate valve has no obstruction in the flow path, resulting in very low friction loss.

2. Main Features of the Gate Valve:

• Valve body cavity using non-toxic epoxy resin,both inside and outside flashboard completely is coated with rubber

• Free of water pollution

• High manufacturing accuracy

• High strength

• Environmental protection and energy saving

• Good visual effect

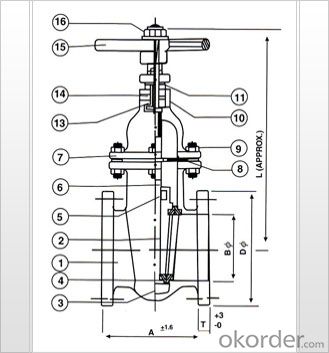

3. Images

4. Gate valve Specification

5.FAQ

1. What's are the characteristics of gate valve?

The distinct feature of a gate valve is the sealing surfaces between the gate and seats are planar, so gate valves are often used when a straight-line flow of fluid and minimum restriction is desired. The gate faces can form a wedge shape or they can be parallel.

2. What is the work principle of gate valve ?

The gate faces can form a wedge shape or they can be parallel. Gate valves are primarily used to permit or prevent the flow of liquids, but typical gate valves shouldn't be used for regulating flow, unless they are specifically designed for that purpose. Because of their ability to cut through liquids, gate valves are often used in the petroleum industry.

3. What is the structure?

Bonnets provide leakproof closure for the valve body. Gate valves may have a screw-in, union, or bolted bonnet. Screw-in bonnet is the simplest, offering a durable, pressure-tight seal. Union bonnet is suitable for applications requiring frequent inspection and cleaning. It also gives the body added strength. Bolted bonnet is used for larger valves and higher pressure applications.

- Q: Valve connections - two how do different connections work?

- The inlet and outlet of valve are respectively connected in two different ways: one end adopts flange connection, the other end adopts thread or socket.

- Q: Valve category can fill the trunk door, branch valve Mody?

- Valve category refers to the type of valve, the big species are divided into: butterfly valve, gate valve, globe valve, ball valve, check valve, control valve, trap and electric valve,

- Q: What does valve J41H-16C mean?

- J- stop valve4- flange type connection1- structure typeH- alloy steel seal16- nominal pressure 16 kgC- body carbon steel

- Q: 1/2, what does 1/4 valve mean? I don't understand. What does this number mean? Have a valve to introduce me, do not copy a pile of online introduction, I want to concise

- I have to answer a simple 1/2 1/4 is American Standard valve diameter to the national standard to calculate it is 1/2=DN15 1/4=DN8Also on the valve size of the meaning of the Wenzhou essence valve factory for you to answer

- Q: 1) the valve plate, valve gate valve, the difference (my personal understanding is that if it is on the ball, called the valve, if the valve is called the gate, is actually a meaning in different valve called, please help me understand it right?)2) valve clack. What's the spool?3) the valve seat is welded inside the valve, or is it directly installed inside without welding?4) when opening the valve, if the valve seat is not welded, then, under the pressure of the medium, why not open the seat?.5) excuse me, pressure self sealing (my personal understanding is that when the valve is closed, the valve plate and valve seat depend on the pressure of the media, and they fit together to seal the effect

- 1. can be understood that way2, check valves, stop valves, and throttle valves are called valves3., welding, thread, and there is a cylindrical indentation, as well as plastic deformation press in4, without opening, there is a sphere or other block, open the moment, the pressure will come down, the media through the channel, attack or blocked by the ball, huh, huh5, the pressure self tight refers to the middle flange, where the greater the pressure, the more reliable sealing, within a certain rangeWhen the cut-off valve diameter is less than 150, the medium is low, the inlet is higher and the outlet diameter is greater than 200Some of them are self locking by thread, and some of the globe valves are equipped with locking devices

- Q: Where is the valve used?

- Oil and gas pipelines, gas stations, gas stations, petrochemical plants, water works,

- Q: What's the caliber of the valve 1/4?

- 1 inches, =25.4 millimeters, 1/4 inches, =2/8 inches, =2 minutes, =DN8 (mm)3/8 inches =3 points =DN10 (mm)1/2 inches, =4/8 inches, =4 minutes, =DN15 (mm)3/4 inches, =6/8 inches, =6 minutes, =DN20 (mm)1 inches =DN25 (mm)1 1/4 inch =DN32 (mm)1 1/2 inch =DN40 (mm)2 inches =DN50 (mm)

- Q: Valve pressure grade division

- Valve (Famen) is a control component in the fluid delivery system. It has the functions of closing, adjusting, guiding, preventing reverse flow, stabilizing voltage, shunting or overflow and releasing pressure.Valves can be used to control air, water, steam, a variety of corrosive media, mud, oil, liquid metal and radioactive media and other types of fluid flow.The valve according to the material is divided into cast iron valves, cast steel valves, stainless steel valves, chrome molybdenum steel, chromium molybdenum vanadium steel valves, valve, dual phase steel valves, plastic valves, non-standard customized valve material etc..

- Q: 1. What does valve 13Cr&FHF mean? 2, valve WC6 (F11) what does that mean? 3. What does valve P280GH mean? 4. What does valve A335P22 mean?Thank you

- The first seems to refer to the material inside the valve, containing Cr of 13% (equivalent to the 1Cr13 of our country), FHF=full face hardThe other refers to the body of the material, the corresponding standard forWC6=ASTM A217 WC6P280GH=EN10222 P280GHA335P22=ASTM A335 P22

- Q: someone else's home has valves, but also checked nothing, in addition to telephone repair, there are other ways? emergency

- Get some water with your neighbors first, property. That's a lie. Other people's homes do not necessarily have water.You need to keep on pressing the property.You should live in a high-rise, if there is no power failure, that is, the water tank pump failure, and urge property repair is.I hope I can help you

Send your message to us

Valve with Competitive Price from Valve Manufacturer in the World

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords