UHP Graphite Electrode Price Trend

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 MT m.t.

- Supply Capability:

- 2000 MT m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Production Description

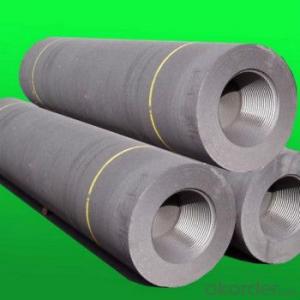

Graphite electrode is made from the domestic first petroleum coke and high quality needle coke

and widely used in the electric arc furnaces for production of alloy steels, metal and other

nonmetallic materials, etc. The graphite electrodes include regular power, high power, super high power, ultra high power and square electrode. The range of diameters covers from 200mm to

700mm. Our products own the following characteristics: low electric resistance, good electric and

thermal conductivity, high oxidation resistance, greater resistance to thermal and mechanical shock, high mechanical strength, high machining accuracy.

package: In pallets

Usage: In steel making

Graphite Electrode Specifications

ITEM | Unit | UHP | HP | RP | |||

350-450mm | 500-700mm | 350-450mm | 500-700mm | 350-450mm | 500-700mm | ||

Bulk Density | g/cm³ | 1.65-1.73 | 1.65-1.74 | 1.62-1.72 | 1.62-1.72 | 1.54-1.61 | 1.54-1.61 |

Specific Resistivity | μΩM | 4.2-6.0 | 4.5-5.8 | 5.5-6.8 | 5.6-7.0 | 7.0-9.0 | 7.0-9.5 |

Flexural Strength | Mpa | 11.0-15.0 | 10.0-14.0 | 10.5-14.5 | 10.0-13.5 | 8.0-11.0 | 7.0-10.0 |

Elastic Modulus | Gpa | 8.5-11.0 | 8.0-12.0 | 6.0-9.3 | |||

CTE (100-600)°C | 10-6/C | 1.30-1.45 | 1.65-1.95 | 1.85-2.25 | |||

ASH | % | 0.1-0.3 | 0.1-0.3 | 0.1-0.3 | |||

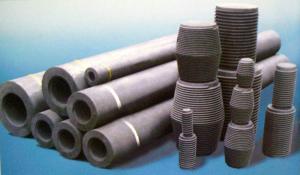

PICTURES:

- Q: Is graphite electrode good for foreign trade?

- Profits can be made for foreign trade. Even if you produce it yourself. Traders take big head. Own production. It's hard for you to play. If you have a client, we can work together

- Q: How to improve the efficiency of graphite electrode milling, please tell me

- When the tool is broken, it will not only stop the continuous processing of the steel, but also affect the quality of the product, which will lead to the scrap of the parts and the waste of the material. Considering the foreseeable future, the graphite electrode will occupy a high position, usually used equipment for processing graphite electrode the highest efficiency mold manufacturers will unremittingly, expand and between those determined to use the hard steel processing manufacturer competition gap. The foundation of micro cutting tools, in terms of graphite electrodes, is one of its most magical words: "high speed."". The spindle speed of the high speed machining center is up to 30000~60000r/min, and the feed speed can be increased to shorten the processing period and improve the quality of the surface and edge. The motor needed to drive this type of spindle is relatively small and light, which helps to reduce cutting power and reduce tool breakage. This is critical because many of the electrodes are complex, and their production involves small, easily broken micro tools (see Figure 1).

- Q: After electrolysis of CuCl2 solution with graphite electrode for a period of time, we can observe that the graphite surface attached to the DC power supply is attached to the red material,And will the color of the solution be deep or shallow?

- Copper ions move toward the cathode, which is the graphite rod connected to the negative electrode of the DC power supply. The color of the solution becomes shallower

- Q: What is the role of the Pt electrode? What is the difference between the graphite electrode and the graphite electrode?

- In the electrochemical process, the electrode should not affect the reaction on the working electrode, so platinum and graphite are often chosen

- Q: In EDM, the electrodes are made of graphite and copper. Please tell us the difference between them

- For example, the electrode is large, and this time it is necessary to consider whether the weight of the electrode is up to standard and, if so, the preferred graphite electrode

- Q: Graphite can be used in acid towers in chemical plants because of graphite

- Ultra high power graphite electrode. A graphite electrode that allows current densities greater than 25A/ cm 2 is allowed. Mainly used in ultra high power steelmaking arc furnace

- Q: How does graphite produce solar cells?

- The team at the Massachusetts Institute of Technology has confirmed that electrodes based on graphene and ITO devices are comparable in efficiency. Although the power conversion efficiency of graphene is 4.2% lower than that of a general silicon cell, it will be competitive for special use in the future.

- Q: How about graphite electrode high-temperature oxidation resistant coating?

- Heat resistant coating is generally able to withstand 300 degrees below the temperature, commonly used aluminum heat-resistant paint, high temperature resistance can withstand higher temperatures, such as 800 degrees or more, commonly used silicone heat-resistant paint

- Q: Graphitized anode, cathode and graphite electrode, respectively How can one differentiate and use differently?

- In electrolysis industry, using graphite anode plate as the anode has a history of more than 100 years, the metal anode is in recent decades, the research and application of metal anode in China late last century, only in 70s the technology related to the research and experiment of metal anode, anode on electrolysis industry, mainly through the silver (2%) (0.5%): low silver lead silver alloy, lead and silver tin antimony alloy, lead calcium alloy and lead silver alloy adding nucleating agents and several stages

- Q: How large is the permissible overload current per square millimeter of the graphite electrode cross section?

- 9A/mm2 safety current should be bare overhead, 5A/mm2 is obviously insulation lines, the indoor environment standards.

1. Manufacturer Overview

| Location | Shizuishan,China |

| Year Established | 2004 |

| Annual Output Value | US$5 Million - US$10 Million |

| Main Markets | " Mid East;Western Europe;North America" |

| Company Certifications | The Authentication certificate of Quality Management system |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 61% - 70% |

| No.of Employees in Trade Department | 50 People |

| Language Spoken: | English;Chinese; |

| b) Factory Information | |

| Factory Size: | Above 300,00 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | Design Service Offered |

| Product Price Range | Average |

Send your message to us

UHP Graphite Electrode Price Trend

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 MT m.t.

- Supply Capability:

- 2000 MT m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords