China HP Graphite Electrode - UHP Graphite Electrode 200-400mm with Nipples

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Graphite electrode is made from the domestic first petroleum coke and widely used in the electric arc furnaces for production of alloy steels, metal and other nonmetallic materials, etc.

The graphite electrodes include regular power, high power, super high power, ultra high power and square electrode.

The range of diameters covers from 200mm to 700mm.

Our products own the following characteristics: low electric resistance, good electric and thermal conductivity, high oxidation resistance, greater resistance to thermal and mechanicalshock, high mechanical strength, high machining accuracy.

Graphite Electrodes Features:

RP HP UHP Graphite Electrode

1.Dia:40-600mm or1.6"-24"

2.Length:250-2400mm or10"-96"

3.Nipples:3TPI,4TPI

4.ISO9001:2008

Graphite Electrodes Application:

An increasing proportion of global steel is made using electric arc furnaces, and the electric arc furnace itself is getting more efficient and making more steel per tonne of electrode

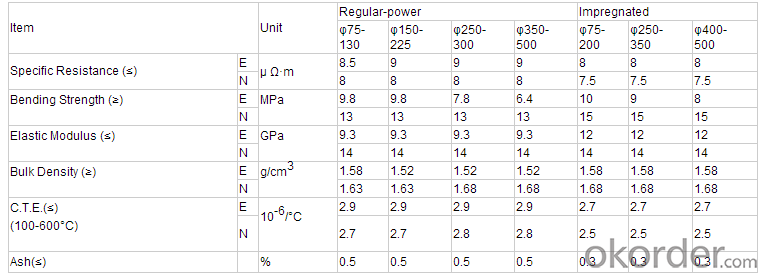

Graphite Electrodes Specifications

Do you know our material of the graphite electrode?

The regular power graphite electrode is made from petroleum coke with a little pitch, which meets the state standards YB/T4088-2000

The high power graphite electrode is made form 70% petroleum coke and 30% imported needle coke, which meets the state standards YB/T4089-2000

Technical data:

Note: The consumption of Electric Arc Furnace(EAF) is about 3-5kg per ton steel. The Ladle Furnace(LF) is about 1kg per ton steel. The converter with Ladle Furnace(LF) is about 0.5kg per ton steel.

FAQs:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: Classification, uses and manufacturers of graphite electrodes

- Graphite as electrode(1) the processing speed is faster: normally, the mechanical processing speed of graphite can be 2~5 times faster than copper, while the discharge processing speed is 2~3 times faster than copper;More material is not easily deformed: obvious advantages in the processing of thin electrodes; copper softening point at about 1000 degrees, easily deformed by heat; graphite sublimation temperature is 3650 degrees; the thermal expansion coefficient of copper is only 1/30.(2) lighter weight: the density of graphite is only 1/5 of copper. When large electrode is used for discharge machining, it can effectively reduce the burden of machine tools (EDM). It is more suitable for large-scale die applications.

- Q: Thermal expansion coefficient of graphite

- Thermal expansion coefficient (100 degrees Celsius --600 degrees Celsius) diameter 200--500 graphite electrode body is not greater than 2.410 of the negative four times per degree Celsius

- Q: Where is the graphite electrode scrap?

- Finally, a bright white Ar-ICP discharge is formed, especially like a drop of water droplets.

- Q: Which department in the steel plant needs graphite in large quantities?

- Steelmaking department. The graphite electrode steelmaking is to enter the electric energy through the graphite electrode to the electric arc furnace, and takes the arc between the electrode end and the furnace charge as the heat source to carry on the steel smelting. The electric arc furnace takes electric energy as heat source, and can adjust the atmosphere in the furnace. It is very beneficial to smelt the steel which contains more easily oxidized elements. Smelting a variety of alloys

- Q: How long is the graphite electrode machining cycle?

- The dust produced in the processing of graphite electrode is relatively large, the possible intrusion to the machine tool guide screw and spindle, which requires a corresponding machining device of graphite graphite dust machine, sealing better, because the graphite toxic.

- Q: Jiqiu conductive graphite electrode, how to compare with copper is relatively large resistance value?

- This is not a good estimate of the sheet graphite resistance after 5mm

- Q: Electrolysis of CuCl2 solutions with graphite electrodes

- CuCl2 refers to a copper chloride ionization ionization ion and chloride ion in aqueous solution, the equivalent of CuCl2 does not exist, but there are only Cu2+ and Cl-, even if there is no electricity, the ionization will happen, because this is the nature of it.

- Q: 800KVA and 12500 EAF transformer data graphite electrode furnace.

- The graphite electrode must be roasted by a cathode or anode baking furnace, and a large amount of harmful gas and dust will be produced during the roasting process.

- Q: I used 12V direct current, graphite electrode electrolysis sodium sulfide solution, the anode produced a large number of black material, this is why ah?

- The problem is this. I have done the test of electrolytic copper sulfate, and the anode produced the same phenomenon. Finally, the chemistry teacher told me that it was because the graphite was broken in the process of electrolysis

- Q: What about graphite electrodes for steel mills?

- Hebei North graphite electrode factory produces various specifications of graphite electrode, with low resistance, high density, small ash, and so on, so that less tons of steel-making, quality is good

Send your message to us

China HP Graphite Electrode - UHP Graphite Electrode 200-400mm with Nipples

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords