Tube Chain-Type Conveyor,Mining Equipment, Pipe Chain Conveyor

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Production

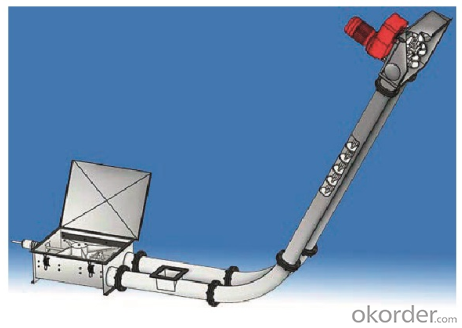

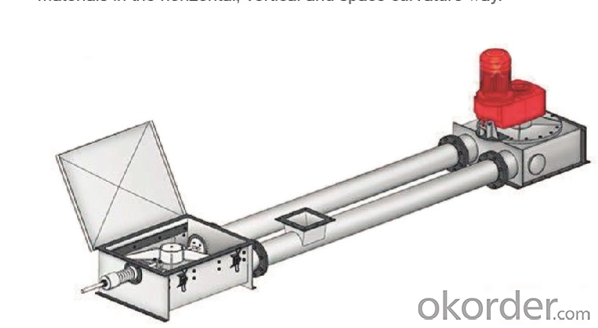

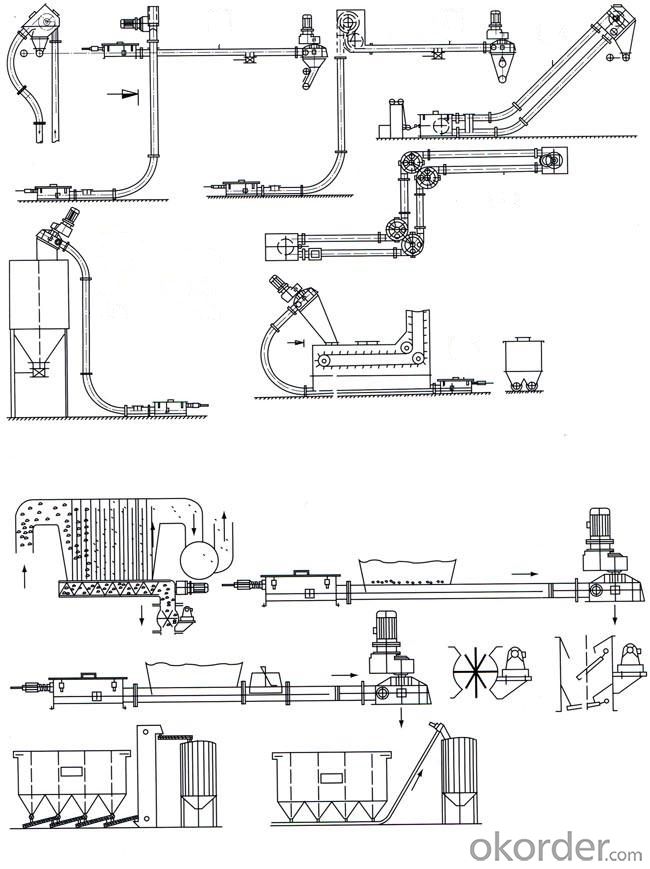

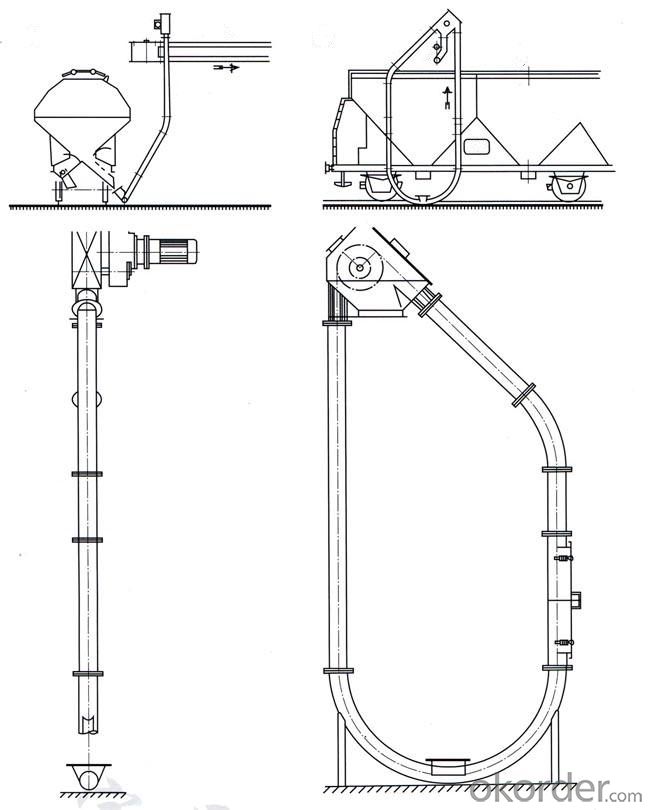

In a closed conduct, with chain drive transmission member piece of material movement along the pipeline. When the horizontal conveyor, the material particles by the chain in the direction of movement of the thrust sheet. When the internal friction of the material layer is greater than the friction material and the outer wall, the material on the sheet with the forward movement of the chain to form a stable stream,when the vertical conveying pipe material particles by the chain upward thrust sheet, since the lower the upper portion of the feed to prevent the material down, resulting in a lateral side of the pressure enhancing the internal friction of the material, when the internal friction of the material is greater than the outer material and the inner wall of the friction material and the weight of the material on the conveyor chain with up sheet, a continuous stream.

Tube chain-type conveyor is a kind of continuous equipment which can make use of chains or steel wire rope to make traction and solidify the materials which are pushed by the scraper for the sake of conveying materials in a continuous way.

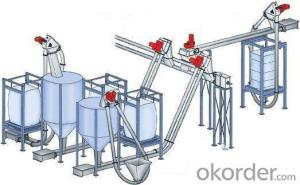

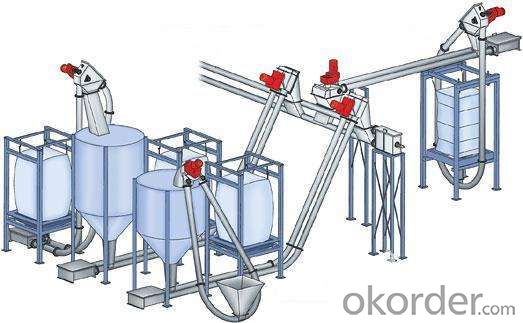

The tube chain-type is mainly applied to the pharmaceutical, chemical engineering, agriculture coal, electricity and other industries to convey the pigment, sulfur, urea, pesticide, industrial salt, coal fines, cement, sands and grains, therefore, which can convey material in the horizontal, vertical and space curvature way.

Technical specification

Tube chain conveyor | Model | Chain pipe diameter(mm) | Transport capacity(t/h) | Transportation distance(m) | Power (Kw) |

TC-50 | Dn50 | 0.5-1.5 | 0~30 | 0.18~2.2 | |

TC-80 | Dn80 | 1-3 | 0~30 | 0.18~3 | |

TC-100 | Dn100 | 2-7 | 0~30 | 0.55~4 | |

TC-125 | Dn125 | 3-10 | 0~30 | 1.1~5.5 | |

TC-150 | Dn150 | 8-25 | 0~30 | 2.2~7.5 | |

TC-200 | Dn200 | 15-50 | 0~30 | 3~15 | |

TC-250 | Dn250 | 30-75 | 0~30 | 5.5~18.5 | |

TC-300 | Dn300 | 60-120 | 0~30 | 7.5~22 |

Performance feature

It has compact structure and small space occupation, meanwhile, which can change the conveying direction in the three-dimensional way.

It is unnecessary to install dust collector on the outlet, what’s more, the gas can filled when materials are conveyed.

The materials can be conveyed smoothly along with the pipeline. There is less damaged materials. The slow curve can make less material particles generate chippings.

It has lowest energy consumption and the most economic operation costs because the whole set of system is driven by one motor.

The system will not be blocked, therefore, it is suitable for conveying materials in multiple forms.

Appliance

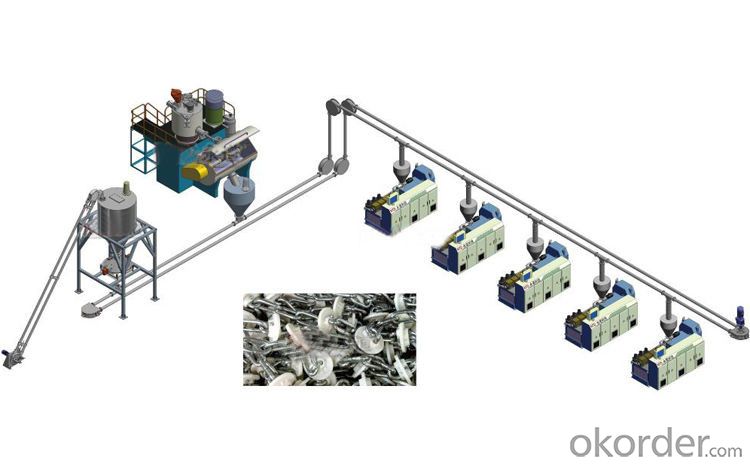

Industry of fine chemicals: Pigment, dye, coating, carbon black, titanium dioxide, iron oxide, ceramic powder, calcium carbonate, calcium carbonate, bentonite, zeolite, kaolin, silicon powder, activated carbon and etc.

Mineral in agricultural chemicals:Urea, ammonium chloride, ammonium bicarbonate, soda powder, solid pesticide, tungsten powder, pesticide auxiliaries, copper concentrate, pulverized coal, phosphate rock powder and aluminum oxide powder and etc.

Building materials:Cement, clay, sand, quartz sand, clay powder, silica, limestone powder, dolomite powder, wood powder, glass fiber, silica and talc powder and etc.

Food industry:Flour, starch, grain, milk powder and food additives and etc.

The pipe chain conveyor is the latest type of conveying equipment in the field of conveying equipment. In recent years, as the state has strengthened environmental protection and rectification measures in various industries, it has been widely applied in chemical, fertilizer, metallurgy, pharmaceutical, feed, plastic and other industries because of its performance advantages of dust-free transportation. After a period of use, the chain conveyor has been widely recognized by all walks of life by virtue of its powerful performance. Not only is the transport efficiency far more than the other conveying equipment, but also it can transfer a variety of powder. Such as granular and small bulk materials can be continuously conveyed. The unique ring pipe sealing structure provides environmental protection for dust free transportation and reduces the direct contact of toxic and harmful substances to the human body. It has two obvious advantages, the single conveyor distance is up to 60m, and the lifting height is up to 40m. In addition, its beautiful appearance, flexible installation and installation performance has also been praised by all industries. The entire production workshop is clean, neat and spacious, and has been upgraded to a different level. It can be said that the chain conveyor will be a major trend in the application of transportation equipment in the future.

Send your message to us

Tube Chain-Type Conveyor,Mining Equipment, Pipe Chain Conveyor

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches