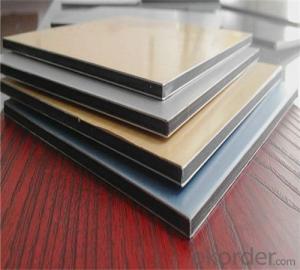

TOBOND silver mirror acp/painting alucobond panel/ pvdf aluminium composite panel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

TOBOND PVDF ALUMINIUM COMPOSITE PANEL

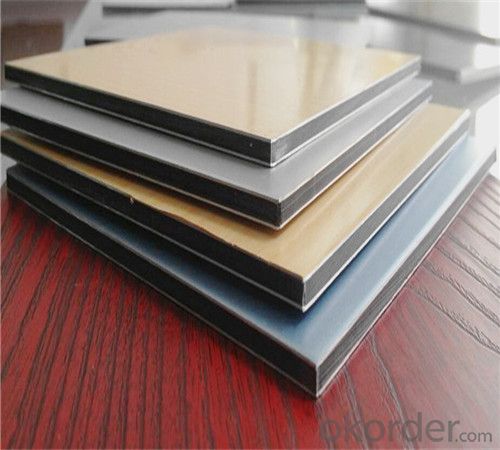

TOBOND PVDF plus Aluminium Composite Panel is special metal surface wall cladding material, compounded with superior aluminum and LDPE Plastic.

Comparing to traditional metal panel, TOBOND ACP is with prime performance of economic efficiency, environment friendly and flexible installation.

ADVANTAGES OF TOBOND ACP

High strength, easy maintenance, 20 years not color fade.

Easy fabrication and installation.

Good Impact Resistance.

Light weight and rigid, reducing buildings load, good performance for quakeproof.

Good Smoothingness.

Various color and size for option.

TOBOND ACP Application

Outer wall cladding, curtain wall.

Redecoration of old buildings outer-wall.

Balconies, indoor partitions.

Units wall cladding

Advertisement signboard

Kitchen and bath room ceiling

Kitchen Cabinet surfacing decoration

Industrial Usage, Vehicle bodies.

STANDARD SIZE OF ACP

Series | Coating | Usage | Panel Thickness | Panel Size(mm) |

PVDF Plus Outdoor Panel | PVDF | Exterior Wall Cladding | 4mm /3mm | 1220*2440 1220*2900 |

Indoor panel | Polyester | Interior Decoration/ Advertisement board | ||

Fireproof panel | PVDF/Polyester | Exterior Wall Cladding/Interior Decoration | ||

Special Size For Option | 6mm/5mm | 1250*2900 1500*2900 1500*5800 | ||

Proceeding Noticed

Portage: panel must be uplifted with its four borders at the same time during portage, do not drag and whop for fear scraping surface of the panel.

Storage: panel must be stored in cool dry place, and placed on flat surface.

Notching; if notching with notching equipment or gong equipment, using milling cutter with half round head≥90 degree. When notching, pls leave 0.2—0.3mm thickness plastic core materials bending with aluminium sheet to increase intension and tenacity, otherwise aluminium sheet may rupture or coating crack.

Bending: forcing equably when bending, molding one-off, do not bend again and again, or Aluminium panel may rupture.

Arcing Machining: using professional bending equipment to machining, forcing inchmeal to make the panel reaching bending radian needed. Do not bending one-off.

Batch: same color panel from different batches may have chromatic aberration, contrast process of chromatic aberration should be added if selling or using panels with different batches panels. Panels can be placed on a plane only there may be visual chromatic aberration.

Installation direction: panels must be install in same direction.

Ripping film: the protective film should be ripped away within 45 days after installation, to avoid survivors left.

Cleaning: clear the panel with water, scours or alcohol over98% with soft sponge. Do not use Chemical Solvents.

- Q: What should I pay attention to? What brand of aluminum plastic plate is good? Aluminum-plastic plate those manufacturers, please list, thank you!

- , Folding aluminum-plastic plate corner, easy to break is not PE material or doping to make false.

- Q: What is the difference between a paint-free board and an aluminum-plastic plate?

- Lacquered board general substrate for the wood bar aluminum plastic plate for plastic

- Q: Aluminum-plastic composite panels and insulation materials have some requirements, such as the layout to 1150mmx2200mm can be reinforced, reinforced strength can meet the requirements?

- Layout is too large, poor control in the construction, the construction technology, base flatness are challenges!

- Q: I made aluminum-plastic curtain wall decoration for 6 years, this year out of their own company to start the contractor, but suffer from no business, ran a lot

- The original construction and materials is a upstream and downstream relationship.We can cooperate with each other to complete the procurement and application of materials.No business, on the one hand the need to accumulate, on the other hand still need to think of a way.

- Q: Aluminum veneer and aluminum sheathed which fire?

- Is aluminum will burn.

- Q: 3d board and aluminum plate prices? What kind of price?

- Three-dimensional board, including polymer composite board, aluminum plate, color plate and other molding materials, in general, polymer composite board, aluminum plate are in the price is higher than the aluminum-plastic plate.

- Q: Curtain wall aluminum-plastic plate, Huatian and Huayuan brand how much difference? Including price.

- In fact, aluminum-plastic plate products, in the face of more professional buyers,

- Q: Aluminum-plastic plate of aluminum and plastic is what glue stick better?

- It should be suppressed

- Q: What is good for plastic and plastic?

- General cooked rubber is more tough, raw rubber is not high temperature, the melting point is low, the melting point of 80 degrees or so, poor elasticity, fragile. Sika high temperature, melting point of about 120 degrees, better elasticity. , Softer for the cooked rubber.

- Q: Aluminum-plastic composite plate should be set where the edge of ribs

- Fill the structural glue between the square tube and the partially folded aluminum plate, used to support the surface wind pressure strength of the cell

Send your message to us

TOBOND silver mirror acp/painting alucobond panel/ pvdf aluminium composite panel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords