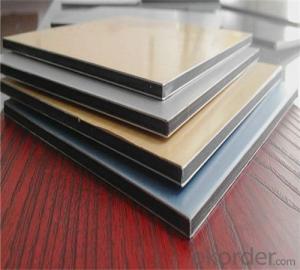

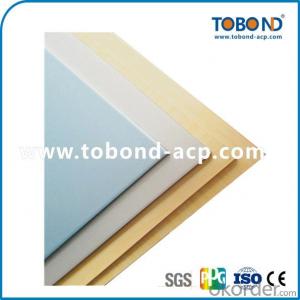

TOBOND alucobond mirror aluminium composite panel

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

TOBOND PVDF ALUMINIUM COMPOSITE PANEL

Size:1220*2440*4mm

TOBOND ACP Application

Outer wall cladding, curtain wall.

Redecoration of old buildings outer-wall.

Balconies, indoor partitions.

Units wall cladding

Advertisement signboard

Kitchen and bath room ceiling

Kitchen Cabinet surfacing decoration

Industrial Usage, Vehicle bodies.

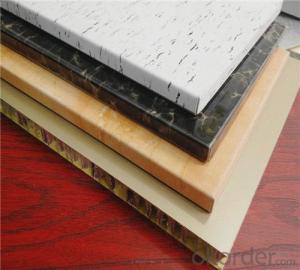

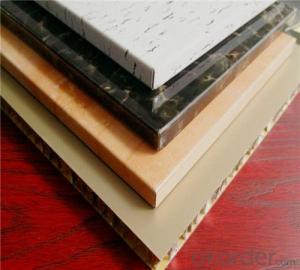

STANDARD SIZE OF TOBOND ACP

Series | Coating | Usage | Panel Thickness | Panel Size(mm) |

PVDF Plus Outdoor Panel | PVDF | Exterior Wall Cladding | 4mm /3mm | 1220*2440 1220*2900 |

Indoor panel | Polyester | Interior Decoration/ Advertisement board | ||

Fireproof panel | PVDF/Polyester | Exterior Wall Cladding/Interior Decoration | ||

Special Size For Option | 6mm/5mm | 1250*2900 1500*2900 1500*5800 | ||

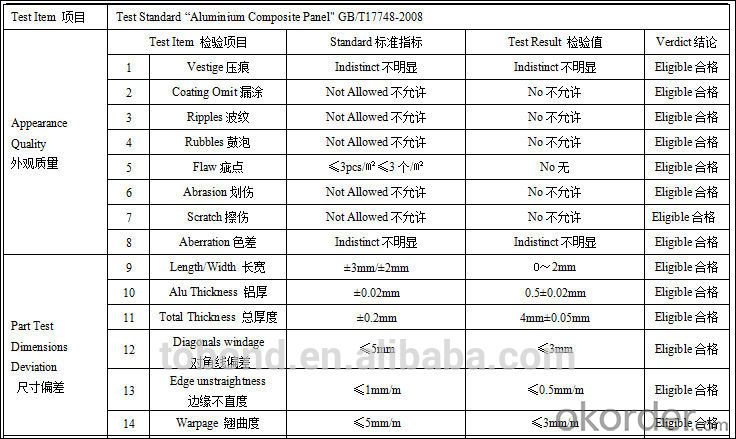

TEST REPORT FOR TOBOND ALUMINIUM COMPOSITE PANEL

|

- Q: Who prawn know that there is no aluminum plate factory in Shenyang it? What is the best brand and contact phone, thank you first, huh, huh

- Generally able to represent the level of China's aluminum-plastic plate development brands are:

- Q: Answer: drawing wire and aluminum plate internal structure Thank you

- The internal structure is made of aluminum-plastic-aluminum composite

- Q: I made aluminum-plastic curtain wall decoration for 6 years, this year out of their own company to start the contractor, but suffer from no business, ran a lot

- Good construction, especially the curtain wall construction of aluminum-plastic board materials, so much and aluminum-plastic plate manufacturers to contact.

- Q: I was ordered to OKorder-made aluminum-plastic plate production, long-term Gong Geng in the capital, because the market "hair with" here, find eye

- East building materials are, a lot of!

- Q: Do billboards facade can only be combined with angle iron and aluminum-plastic panels do

- Aluminum-plastic composite board is a chemically treated coated aluminum sheet for the surface material, with polyethylene plastic as the core material, in the special aluminum-plastic plate production equipment from the processing of composite materials. The unique performance of the aluminum-plastic composite panel itself determines its wide range of uses: it can be used for building facades, curtain wall panels, retrofits of old buildings, interior walls and ceilings, advertising signs, display stands, engineering. Belonging to a new type of building decoration materials.

- Q: Besides how to install aluminum-plastic panels, what is the process? What do you need?

- With wood keel backing and then paste the plate and then paste the plastic plate is not standardized construction method.

- Q: Reflective film mounted to the aluminum-plastic plate, just mounted on a very flat, a night arch on why

- First, the floor is not clean, the second is the reflective film adhesive problems.

- Q: Aluminum slab plate and aluminum-plastic plate ceiling approach is not the same

- Aluminum plate is made of pre-formed, and a matching keel and boom and other accessories. Installation is more convenient. And aluminum plate to do ceiling materials, the need for on-site processing and molding, and arbitrariness is relatively strong, so the specific approach is still different of

- Q: My company has 20,000 square meters of color steel plate need to be cleaned. 150,000 square aluminum plate needs cleaning, may I ask which cleaning company in Guangzhou more professional? Which cleaning company is cheap, cleaning effect is better?

- Jiajia Le cleaning company Services: professional to provide hotels, commercial buildings, shopping malls, factories, residential property district, a comprehensive clean, maintenance and maintenance of integrated services company. The company has a high-quality external wall cleaning, cleaning, land reclamation, stone renovation, floor waxing, carpet cleaning, cleaning, cleaning services, professional team, no matter when and where to inquire negotiations, the company will sincerely for your service! The company's service concept is: customer first, integrity first, service first.

- Q: Which brand of aluminum veneer is good, where to find suppliers?

- Where to find suppliers, which depends on which one you choose. Choose their own to find or cost check it.

Send your message to us

TOBOND alucobond mirror aluminium composite panel

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords