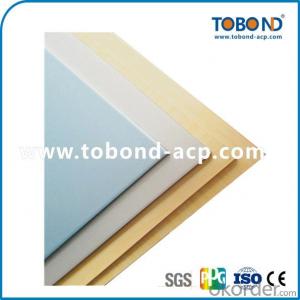

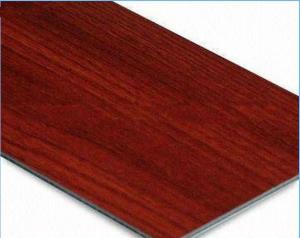

Golden mirror acp / TOBOND aluminum composite panel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

TOBOND PVDF ALUMINIUM COMPOSITE PANEL

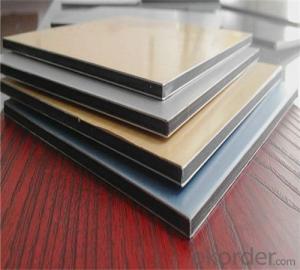

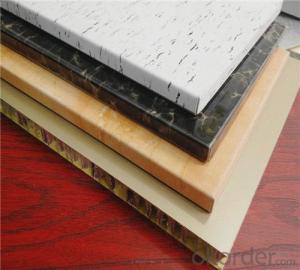

TOBOND PVDF plus Aluminium Composite Panel is special metal surface wall cladding material, compounded with superior aluminum and LDPE Plastic.

Comparing to traditional metal panel, TOBOND ACP is with prime performance of economic efficiency, environment friendly and flexible installation.

ADVANTAGES OF TOBOND ACP

High strength, easy maintenance, 20 years not color fade.

Easy fabrication and installation.

Good Impact Resistance.

Light weight and rigid, reducing buildings load, good performance for quakeproof.

Good Smoothingness.

Various color and size for option.

STANDARD SIZE OF ACP

Series | Coating | Usage | Panel Thickness | Panel Size(mm) |

PVDF Plus Outdoor Panel | PVDF | Exterior Wall Cladding | 4mm /3mm | 1220*2440 1220*2900 |

Indoor panel | Polyester | Interior Decoration/ Advertisement board | ||

Fireproof panel | PVDF/Polyester | Exterior Wall Cladding/Interior Decoration | ||

Special Size For Option | 6mm/5mm | 1250*2900 1500*2900 1500*5800 | ||

Proceeding Noticed

Portage: panel must be uplifted with its four borders at the same time during portage, do not drag and whop for fear scraping surface of the panel.

Storage: panel must be stored in cool dry place, and placed on flat surface.

Arcing Machining: using professional bending equipment to machining, forcing inchmeal to make the panel reaching bending radian needed. Do not bending one-off.

Batch: same color panel from different batches may have chromatic aberration, contrast process of chromatic aberration should be added if selling or using panels with different batches panels. Panels can be placed on a plane only there may be visual chromatic aberration.

Installation direction: panels must be install in same direction.

Ripping film: the protective film should be ripped away within 45 days after installation, to avoid survivors left.

- Q: I have thousands of pounds of aluminum slab scrap where the acquisition, how much money a kilogram

- Then you sell seven yuan it

- Q: What are the qualifications of aluminum-plastic panels on the external walls? anxious

- Three enterprises: can bear the amount of individual contract does not exceed 5 times the registered capital of enterprises and individual projects in the 3000 square meters and below the height of 30 meters and below the construction of the curtain wall works.

- Q: Guiqiu, how can there be aluminum-plastic plate, ah, need to recover ah, please help Oh, thank you

- I have aluminum panels, only do not sell.

- Q: 28 silk 4MM aluminum plate how much money, use it to do the outer wall about how much money

- Aluminum plate manufacturers in the actual manufacturing process, the thickness of aluminum plate often maintain a negative difference.

- Q: I made a monitoring project, the bank inside the aluminum-plastic plate was I turned a hole. The above requirements we must rectify. Now want to ask you how to make up. I heard that the wrench is shipped over the sea. I'm thinking all about it all day.

- First look at how much hole? If small, then you can put up with what putty;

- Q: Does anyone know that the bathroom cabinet is a solid wood cabinet or a good PVC cabinet?

- Environmental protection, the harm of furniture products on the human body mainly from the release of formaldehyde in man-made plate, imports of oak, solid wood itself is low in the release of formaldehyde materials, and wood-based panels can not achieve this. Bathroom cabinet stainless steel stent long damp, the choice should pay attention. The main component of stainless steel is nickel and chromium alloy, to identify whether the quality of stainless steel, one of the methods is to take magnets to test, high-quality stainless steel magnetic is very small, can not be easily replaced by iron stone elements, not like iron attracted by the magnet The Can be sucked up is mixed with iron, this is easy to rust the inferior stainless steel, stainless steel corrosion resistance, strength, plasticity is relatively weak. cheap price. Stainless steel thickness should also pay attention. Selection of stainless steel must have a strong chemical stability, sufficient strength and plasticity.

- Q: Is the aluminum-plastic plate plastic? What is the difference between the two? What are their uses?

- Belong to the same kind of decorative materials. Its advantages are: surface smooth, uniform color, long life, simple construction and so on. Generally used for building facades, store decoration, can also be used for home interior decoration.

- Q: I am in Kunming, but there is a site in OKorder side, want to buy aluminum plastic plate to decorate the store, there is no authentic aluminum plate manufacturers ah

- Kunming Yulong Road, there is a way to sell aluminum-plastic plate, you can ask

- Q: Does the aluminum plate itself fire? Not aluminum plate

- Metal can not set fire to say that aluminum has heat absorption fast heat fast characteristics

- Q: Aluminum-plastic board to install a seamless splicing or leave a gap

- To stay, this is the expansion joints. Or easy to drum (package), serious will fall off

Send your message to us

Golden mirror acp / TOBOND aluminum composite panel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords