Tk 6491509001742 AA3003 H12 Direct Rolled Aluminum Coil China Supply

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of AA3003 H12 Direct Rolled Aluminum Coil China Supply

Material | Alloy Aluminum 6063,6061,6005 or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

2. Application of AA3003 H12 Direct Rolled Aluminum Coil China Supply

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of AA3003 H12 Direct Rolled Aluminum Coil China Supply

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

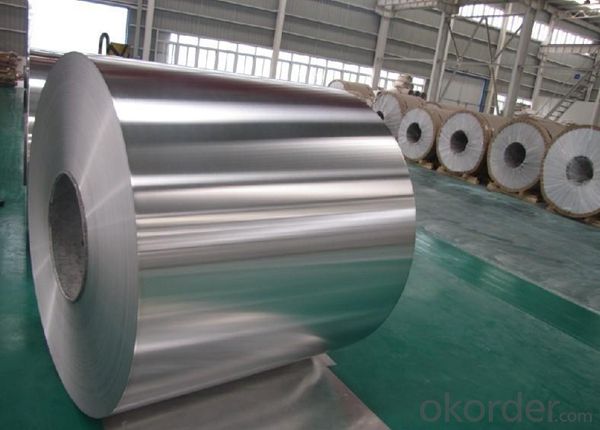

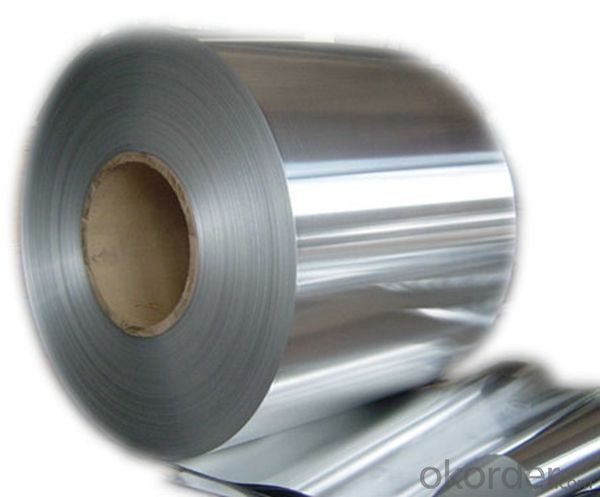

5. Image of AA3003 H12 Direct Rolled Aluminum Coil China Supply

6. Package and shipping of AA3003 H12 Direct Rolled Aluminum Coil China Supply

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Are there any limitations on the width-to-thickness ratio of aluminum coils?

- Yes, there are limitations on the width-to-thickness ratio of aluminum coils. The width-to-thickness ratio is an important factor in determining the overall strength and performance of aluminum coils. If the ratio is too high, it can lead to issues such as buckling, warping, or even failure of the coil. The specific limitations on the width-to-thickness ratio depend on various factors such as the alloy composition, temper, and intended application of the aluminum coil. Different alloys and tempers have different mechanical properties and can handle different ratios. Additionally, the intended application of the coil, such as roofing, automotive, or packaging, may have specific requirements for the width-to-thickness ratio. Manufacturers typically provide guidelines and specifications for the acceptable width-to-thickness ratio based on their product offerings. These guidelines ensure that the coils are used within their intended capabilities and prevent any issues related to excessive width-to-thickness ratios. It is important for users and designers to consider these limitations and guidelines when selecting and utilizing aluminum coils. Failure to adhere to these limitations can result in compromised performance, increased risk of damage, and potential safety concerns. Therefore, it is crucial to consult the manufacturer's recommendations and industry standards to determine the appropriate width-to-thickness ratio for a given application.

- Q: Are parakeets allergic to aluminum because I wanted to use a metal pie pan for a bird bath.

- ask a nice bird vet

- Q: Is it possible to use a soldering iron to fix a damaged or broken aluminum coil?

- <p>Using a soldering iron to repair an aluminum coil is not typically effective. Aluminum has a high thermal conductivity and doesn't bond well with solder, making it difficult to create a strong joint. Instead, consider using specialized aluminum welding techniques or brazing, which involves using a filler metal with a melting point higher than the base metal. For small repairs, you might also explore the use of aluminum repair epoxy or other adhesives designed for metal bonding. Always ensure to follow safety precautions and consult with a professional if the repair is complex or if the coil is part of a critical system.</p>

- Q: Can aluminum coils be used in the production of solar reflectors?

- Certainly! Solar reflectors can utilize aluminum coils in their production. Due to its exceptional reflectivity and durability, aluminum is widely employed in the manufacturing of these reflectors. The coils can be manipulated and molded into the desired shape for the reflector, facilitating efficient sunlight reflection onto the solar panels. Furthermore, aluminum's lightweight nature simplifies its handling and installation in solar reflector systems.

- Q: How do aluminum coils compare to magnesium coils in terms of strength?

- In comparison to magnesium coils, aluminum coils typically exhibit greater strength. Aluminum is renowned for its exceptional strength-to-weight ratio, thus rendering it a favored option across multiple industries. It boasts a higher tensile strength and superior resistance to deformation when subjected to stress, unlike magnesium. Moreover, aluminum possesses a higher yield strength, enabling it to withstand more substantial loads before succumbing to permanent deformation. Conversely, magnesium, despite its lighter nature, tends to possess inferior strength attributes. Although magnesium coils may prove beneficial in specific scenarios where weight plays a crucial role, aluminum coils are generally favored for their strength and longevity.

- Q: How are aluminum coils used in the production of cookware?

- Aluminum coils play a crucial role in the production of cookware due to their unique properties and versatility. These coils are used as the primary material in the manufacturing process of various types of cookware, including pots, pans, and baking sheets. Firstly, aluminum coils are known for their excellent heat conductivity, which allows for efficient and even heat distribution throughout the cookware. This property ensures that food is cooked evenly and reduces the chances of hot spots or uneven cooking. This is particularly important for achieving optimal cooking results and preventing food from burning or sticking to the cookware. Secondly, aluminum coils are lightweight yet durable, making them ideal for cookware production. The lightweight nature of aluminum ensures that the cookware is easy to handle and maneuver while cooking, reducing the risk of accidents or injuries. Additionally, aluminum's durability ensures that the cookware can withstand high temperatures, constant use, and the rigors of everyday cooking without warping or deforming. Furthermore, aluminum coils are highly resistant to corrosion and rust, making them suitable for cookware that comes into contact with food and liquids. This property ensures that the cookware remains hygienic and safe for cooking purposes, as aluminum does not react with acidic or alkaline ingredients commonly used in cooking. Moreover, aluminum coils are malleable and can be shaped into various cookware designs, including pots, pans, and bakeware with different sizes, shapes, and depths. This flexibility allows for the production of cookware that caters to different cooking techniques and preferences. In terms of production, aluminum coils are typically subjected to a series of manufacturing processes, such as rolling, annealing, and stamping, to transform them into the desired cookware shape. These processes ensure the final cookware product meets the required specifications in terms of thickness, strength, and appearance. In conclusion, aluminum coils are essential in the production of cookware due to their excellent heat conductivity, lightweight yet durable nature, resistance to corrosion, and malleability. These properties enable the creation of high-quality cookware that provides efficient and even cooking results, durability, and ease of use. Overall, aluminum coils contribute significantly to the functionality and performance of cookware, making them a popular choice in the industry.

- Q: How are aluminum coils measured and specified?

- Aluminum coils are typically measured and specified using two key parameters: thickness and width. The thickness of an aluminum coil refers to the thickness of the aluminum sheet used to make the coil, and it is commonly measured in millimeters (mm) or gauge. The width of a coil, on the other hand, refers to the width of the aluminum sheet that is wound into a coil shape and is usually measured in inches or millimeters. These measurements and specifications are crucial in determining the suitability of the coil for various applications and manufacturing processes.

- Q: Describe the manufacturing steps involved in producing aluminum coils.

- <p>The production processes of aluminum coils involve several key steps. Initially, aluminum ingots are melted in a furnace. The molten aluminum is then transferred to a casting machine where it is cast into a continuous strip. This strip is cooled and passed through a series of rollers to reduce its thickness and achieve the desired coil gauge. The rolling process can be hot or cold, depending on the final product's properties. After rolling, the aluminum coil may undergo annealing to improve its ductility and strength. It is then cleaned, oiled, and wound into coils. Quality control checks are performed throughout the process to ensure the coils meet specific standards. Finally, the aluminum coils are packaged and shipped for various applications such as construction, automotive, and packaging industries.</p>

- Q: I was going to buy a turkey roaster pan today and an elderly couple stopped me and told me to buy another one that was made of stainless steel instead of aluminum because aluminum does something to your brain. What is the story?Just curious. Does this also ring true for using a sheet of aluminum foil over baking sheets while cooking cookies or fries or something? I always coat my cookie sheets with foil. Just curious...

- For okorder /19

- Q: How are aluminum coils protected against moisture during storage?

- Various methods and materials are typically employed to safeguard aluminum coils against moisture during storage. One commonly utilized technique involves the application of a protective coating, such as a thin layer of oil or a corrosion-resistant film, which establishes a barrier between the coil and any moisture present in the surroundings. This coating effectively prevents direct contact between the aluminum surface and water, thereby minimizing the likelihood of corrosion or other forms of moisture-induced harm. In addition to protective coatings, it is possible to store aluminum coils in a controlled environment with low humidity levels. This can be accomplished by placing the coils in a dry warehouse or utilizing dehumidifiers to eliminate excess moisture from the storage area. By regulating the humidity, the probability of moisture condensation on the coils is diminished, affording them further protection against potential damage. Moreover, appropriate packaging plays a vital role in shielding aluminum coils from moisture during storage. Frequently, the coils are enveloped in moisture-resistant materials, such as plastic or moisture-proof paper, which create a barrier to prevent moisture from reaching the coils. Additionally, the packaging is often sealed to establish an airtight environment, thereby minimizing the chances of moisture infiltration. Regular inspection and maintenance are also crucial to ensure the ongoing protection of aluminum coils during storage. This entails examining the integrity of the protective coatings, monitoring the storage environment for any fluctuations in humidity levels, and promptly addressing any indications of moisture damage. On the whole, the utilization of protective coatings, controlled storage environments, appropriate packaging, and regular maintenance are key elements in safeguarding aluminum coils against moisture during storage. By implementing these measures, the risk of moisture-related damage is significantly reduced, ensuring the coils' quality and integrity until they are ready for utilization.

Send your message to us

Tk 6491509001742 AA3003 H12 Direct Rolled Aluminum Coil China Supply

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords