Packaging Tape Manufacturer Double Sided Tissue Tape Solvent Based Acrylic Black Color SGS & ISO9001

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Double Sided Tissue Tape Solvent Based Acrylic Black Color SGS&ISO9001

1. Structure of Double Sided Tissue Tape Description

Double Sided Tissue Tape is of tissue as the carrier, coating with hot melt adhesive, water based acrylic, solvent based acrylic. Double Sided Tissue Tape is widely used for bonding, fixing for leather, foam, sponge, garment, shoe, luggage, plastic, paper splicing and stationery.

2. Main Features of the Double Sided Tissue Tape

Excellent in adhesion and flame retardant

Resistance to cold, heat and aging.

High Temperature stability

High mechanical strength and good impact resistance

Ideal for use in dispensers

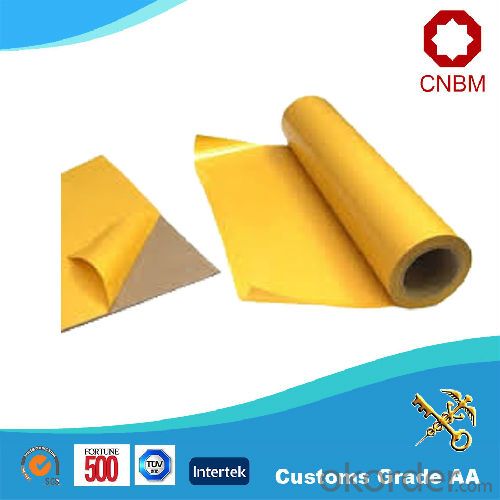

3. Double Sided Tissue Tape Images

4. Double Sided Tissue Tape Specification

| Item | Double Sided Tissue Tape |

| Adhesive | hot melt |

| Carrier | tissue |

| Thickness | 80 |

| Initial Tack (14# mm) | 120 |

| Holding Power (h) | 2 |

| Temperature Resistance (DC) | 60 |

| Size | 50mm*30m, etc. |

5. FAQ

Q1. How about our company?

CNBM International Corporation (CNBM International) is a state-owned company and we have sound business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization, which also represents an essential progress in our globalization target. We have over twenty years experiences.

Q2. What can we do for you?

Sample of Double Sided Tissue Tape is available.

Your inquiry will be replied within 12 hours.

24 hours service

Well-trained & experienced sales representative are ready to answer you.

Q3. How long can you receive the product?

Within 7-15 working days after receiving your deposit

- Q: Are there any safety precautions to consider when using packaging tape?

- Yes, there are several safety precautions to consider when using packaging tape. Firstly, it is important to ensure that you are using the tape in a well-ventilated area, as some adhesive fumes can be harmful if inhaled excessively. Additionally, it is crucial to handle the tape dispenser with care to avoid any injuries. Make sure to use proper hand placement and avoid placing your fingers too close to the cutting blade to prevent accidental cuts. Furthermore, when using packaging tape, it is advisable to wear appropriate protective gear, such as gloves, to protect your hands from any potential adhesive residue or cuts. Lastly, it is essential to store the tape in a safe and secure place, away from children or pets, to prevent any accidental ingestion or misuse. By following these safety precautions, you can ensure a safe and efficient use of packaging tape.

- Q: Is packaging tape safe to use on plastic picture frames?

- Packaging tape can generally be used on plastic picture frames without any safety concerns. Its design emphasizes strength and durability, making it ideal for securing various items, including plastic frames. However, before using packaging tape on plastic picture frames, it is crucial to take a few factors into account. Firstly, ensure that the tape does not contain any adhesive that could harm the frame or leave behind residue. It is recommended to test a small, inconspicuous area of the frame with the tape before applying it to the entire frame. Additionally, when removing the tape, exercise caution to prevent any potential damage to the frame. Overall, by being cautious and selecting an appropriate tape, packaging tape should pose no safety risks when used on plastic picture frames.

- Q: Can packaging tape be used for repairing torn paper?

- No, packaging tape is not suitable for repairing torn paper. It is designed for sealing and securing packages, not for mending torn paper.

- Q: What materials are commonly used for packaging tape?

- The most commonly used materials for packaging tape are polypropylene, PVC, and paper.

- Q: Is packaging tape waterproof?

- Typically, packaging tape possesses waterproof properties. Its design aims to resist moisture effectively and create a formidable seal, thereby preventing water infiltration into the package. Nonetheless, it is crucial to acknowledge that the degree of waterproofing can vary depending on the quality and type of packaging tape employed. Certain tapes may offer a more reliable seal compared to others, hence it is advisable to opt for a tape explicitly crafted for packaging and sealing applications.

- Q: Does packaging tape come in different textures?

- Yes, packaging tape does come in different textures. While the most common type of packaging tape is smooth and glossy, there are also textured variations available. Some examples of textured packaging tape include rubberized tapes, which have a soft and grippy texture, and paper-based tapes, which have a rougher texture similar to masking tape. These textured tapes are often used for specific purposes, such as providing extra grip or adhering to difficult surfaces. However, it's important to note that textured packaging tapes may have different adhesive properties and may not be suitable for all applications.

- Q: Is packaging tape safe for use on painted surfaces or walls?

- Packaging tape is generally considered safe when used on painted surfaces or walls. However, it is crucial to exercise caution and employ proper techniques to minimize the risk of potential damage. To ensure that the tape does not peel off or harm the paint, it is advisable to first test a small, inconspicuous area before applying it. Moreover, it is recommended to remove the tape gently and slowly to avoid any paint peeling or residue. In cases where the paint is delicate or the tape has been left on for a prolonged period, there is a slight possibility of minor damage such as slight paint discoloration or removal. Therefore, it is always wise to handle packaging tape with care and take necessary precautions to safeguard the painted surfaces or walls.

- Q: Are there any eco-friendly options for packaging tape?

- In today's market, there are various eco-friendly options for packaging tape. Typically, traditional packaging tapes are made from plastic materials like polypropylene or PVC, which are harmful to the environment and not biodegradable. However, there have been developments in creating eco-friendly alternatives to tackle this issue. Some of these options include: 1. Packaging tape made from paper: These tapes are crafted from renewable resources like paper and natural adhesives. They are both biodegradable and compostable, making them a sustainable choice for packaging requirements. 2. Gummed paper tape, also known as water-activated tape: This type of tape is made from paper and requires water to activate the adhesive. It forms a strong bond when applied to boxes and provides tamper-proof sealing. Additionally, water-activated tape is biodegradable and can be recycled along with the packaging it is used on. 3. Biodegradable and compostable tape: These tapes are manufactured using plant-based materials such as cellulose or polylactic acid (PLA). They are designed to naturally break down over time, minimizing their impact on the environment. Some options are certified as compostable, meaning they can be added to compost piles or sent to composting facilities. 4. Recycled plastic tape: Although traditional plastic tapes are not environmentally friendly, there are recycled plastic tape options available in the market. These tapes are produced using recycled plastic materials, reducing the demand for new plastic and promoting a circular economy. When searching for eco-friendly packaging tape, it is crucial to consider certifications such as the Forest Stewardship Council (FSC) for paper-based tapes or the Biodegradable Products Institute (BPI) certification for compostable tapes. By opting for these alternatives, individuals and businesses can minimize their environmental impact and contribute to a more sustainable future.

- Q: Is packaging tape safe for use on photos or artwork?

- Yes, packaging tape is generally safe for use on photos or artwork, but it is not the ideal choice. Packaging tape is designed for securing boxes and packages, and it may not be archival quality, meaning it may not provide long-term protection for photos or artwork. Using packaging tape on photos or artwork can potentially damage the surface or leave residue when removed. It may also yellow or discolor over time, affecting the appearance of the artwork or photo. For preserving the integrity and longevity of photos or artwork, it is recommended to use acid-free archival tape specifically designed for this purpose. Archival tape is made with materials that are safe for use on delicate surfaces, and it is designed to be easily removable without causing any damage. In conclusion, while packaging tape can be used in a pinch, it is advisable to use archival tape to ensure the best protection for your valuable photos or artwork.

- Q: Can packaging tape be used for sealing foam?

- Yes, packaging tape can be used for sealing foam. Packaging tape is commonly used for sealing boxes and packages, but it can also be used effectively to seal foam. When using packaging tape to seal foam, it is important to ensure that the tape is securely adhered to the foam surface to create a tight seal. This can be achieved by applying pressure to the tape after it has been applied. Additionally, it is recommended to use a tape that is specifically designed for sealing foam, as these tapes often have stronger adhesive properties and are more resistant to temperature changes and moisture. Overall, packaging tape can be a convenient and effective option for sealing foam.

Send your message to us

Packaging Tape Manufacturer Double Sided Tissue Tape Solvent Based Acrylic Black Color SGS & ISO9001

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches