Electrolytic Tinplate Coils and Sheets for Tin Cans Making

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 7000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Electrolytic Tinplate Coils and Sheets for Tin Cans Making Description

Electrolytic Tin Plate Coils and Sheets for Foods Metal Packaging, is one thin steel sheet with a coating of tin applied by electrolytic deposition. Tinplate made by this process is essentially a sandwich in which the central core is strip steel. This core is cleaned in a pickling solution and then fed through tanks containing electrolyte, where tin is deposited on both sides. As the strip passes between high-frequency electric induction coils, it is heated so that the tin coating melts and flows to form a lustrous coat.

2.Main Features of the Electrolytic Tinplate Coils and Sheets for Tin Cans Making

Appearance – Electrolytic Tin Plate is characterized by its beautiful metallic luster. Products with various kinds of surface roughness are produced by selecting the surface finish of the substrate steel sheet.

Paintability and printability – Electrolytic Tin Plates have excellent paintability and printability. Printing is beautifully finished using various lacquers and inks.

Formability and strength – Electrolytic Tin Plates have got very good formability and strength. By selecting a proper temper grade, appropriate formability is obtained for different applications as well as the required strength after forming.

Corrosion resistance – Tinplate has got good corrosion resistance. By selecting a proper coating weight, appropriate corrosion resistance is obtained against container contents. Coated items should meet 24 hour 5 % salt spray requirement.

Solderability and weldability – Electrolytic Tin Plates can be joined both by soldering or welding. These properties of tinplate are used for making various types of cans.

Hygienic – Tin coating provides good and non toxic barrier properties to protect food products from impurities, bacteria, moisture, light and odours.

Safe – Tinplate being low weight and high strength makes food cans easy to ship and transport.

Eco friendly – Tinplate offers 100 % recyclability.

Tin is not good for low temperature applications since it changes structure and loses adhesion when exposed to temperatures below – 40 deg C.

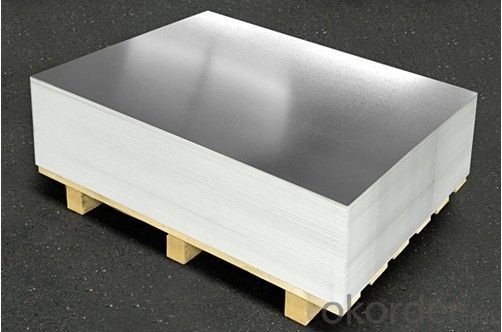

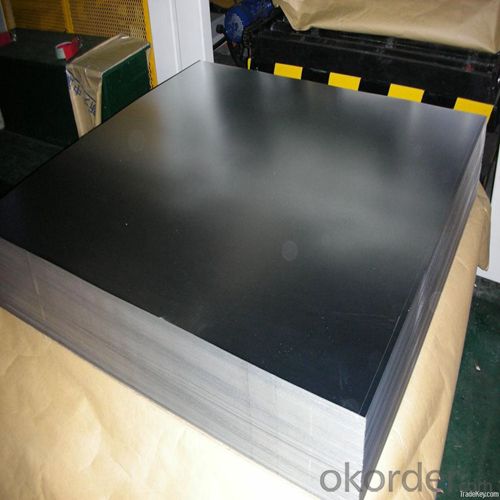

3.Electrolytic Tinplate Coils and Sheets for Tin Cans Making Images

4.Electrolytic Tinplate Coils and Sheets for Tin Cans Making Specification

Standard | ISO 11949 -1995, GB/T2520-2000,JIS G3303,ASTM A623, BS EN 10202

|

Material | MR,SPCC |

Thickness | 0.15mm - 0.50mm |

Width | 600mm -1150mm |

Temper | T1-T5 |

Annealing | BA & CA |

Coil Inner Diameter | 508mm |

Weight | 6-10 tons/coil 1~1.7 tons/sheets bundle |

Passivation | 311 |

Oil | DOS |

Surface | Finish,bright,stone,matte,silver |

5.FAQ of Electrolytic Tinplate Coils and Sheets for Tin Cans Making

- How are the Electrolytic Tin Plates specified?

The Electrolytic Tin Plates are specified as per the steel base, extent of tempering, the coating weight, annealing method and the surface finish.

- How many types there are for base steels?

The base steels are of three types: Type MR, L, D

- Q: How does tinplate perform in terms of heat resistance?

- Tinplate offers moderate heat resistance, as it can withstand temperatures up to around 250 degrees Celsius without significant deformation or damage. However, it is not suitable for extreme heat applications and may lose its structural integrity or experience discoloration at higher temperatures.

- Q: What are the different coating options for tinplate?

- Some of the different coating options for tinplate include tin-free steel (TFS), electrolytic tinplate (ETP), and tin coating with different grades or thicknesses.

- Q: How does tinplate packaging contribute to product protection against breakage?

- Tinplate packaging contributes to product protection against breakage by providing a strong and durable barrier that can withstand external pressure and impact. The rigid nature of tinplate makes it resistant to deformation and ensures that the packaged product remains intact and secure during transportation and handling. Additionally, tinplate packaging offers excellent resistance to moisture, corrosion, and temperature changes, further safeguarding the product from damage.

- Q: Can tinplate be used for kitchenware?

- Yes, tinplate can be used for kitchenware. Tinplate is a type of steel coated with a thin layer of tin, which provides protection against corrosion and enhances its aesthetics. It is commonly used for making cans, containers, and other kitchen utensils like bowls, trays, and cooking pans. Tinplate is durable, easy to clean, and resistant to rust, making it suitable for various kitchen applications.

- Q: How is tinplate coated for household appliances?

- Tinplate is coated for household appliances through a process called electrolytic tinplating. The tinplate is first cleaned and then immersed in an electrolyte bath containing tin salts. An electric current is passed through the bath, causing tin ions to be deposited onto the surface of the tinplate, creating a thin layer of tin coating. This coating provides corrosion resistance and enhances the aesthetic appeal of the household appliances.

- Q: How is tinplate coated for corrosion resistance?

- Tinplate is coated for corrosion resistance through a process called electrolytic tinning. In this process, a thin layer of tin is deposited onto the surface of the tinplate using an electric current. This tin coating acts as a protective barrier, preventing the underlying steel from coming into direct contact with oxygen and moisture, which are the main causes of corrosion.

- Q: How does tinplate contribute to the performance of ammunition?

- Tinplate contributes to the performance of ammunition by providing a durable and corrosion-resistant outer coating. This protective layer ensures that the ammunition remains intact and functional even under harsh environmental conditions, preventing rust and degradation. Additionally, tinplate's smooth surface facilitates easy loading and extraction of ammunition, enhancing reliability and efficiency during use. Overall, tinplate plays a crucial role in preserving the quality and performance of ammunition, ensuring its effectiveness and safety for users.

- Q: How does tinplate packaging contribute to product visibility?

- Tinplate packaging contributes to product visibility through its glossy and reflective surface, allowing consumers to easily spot and identify the product on shelves. Additionally, tinplate packaging can be customized with vibrant colors and eye-catching designs, further enhancing the visibility and attractiveness of the product.

- Q: What's the advantage of metal containers in packing tea?

- Aluminum cans are exquisite. Well done! That's a relatively high cost.3: tin cans cost even higher. Tin can hold tea for hundreds of years. Firm, able to sculpt, and end as a work of art.

- Q: How does tinplate compare to other packaging materials?

- Tinplate offers several advantages compared to other packaging materials. It is highly durable, providing excellent protection for the packaged goods. Tinplate is also resistant to corrosion, ensuring the longevity of the packaging. It is lightweight, making it cost-effective for transportation and storage. Additionally, tinplate is versatile, allowing for various shapes and sizes of packaging, and it provides an attractive appearance, enhancing the visual appeal of the product. Overall, tinplate is a reliable and efficient packaging material that offers numerous benefits in comparison to other alternatives.

Send your message to us

Electrolytic Tinplate Coils and Sheets for Tin Cans Making

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 7000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords