Tinplate with Prime Quality for Tin Box Making

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Tinplate Specification

Tinplate, as the name suggests, is coated on both sides with pure tin at various coating weights between 1 and 12 grams per square meter. It has extremely beautiful metalllic luster as well as excellent properties in corrosion resistance, solder ability, and weld ability.

Tinplate Applications

Tinplate is widely used for making all types of containers, electrical machinery parts and many other products.

Chemicals and painting cans

Dry food cans, such as fancy cans, biscuit cans, milk powder cans, tea cans.

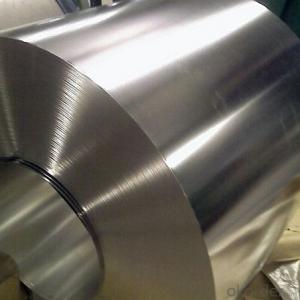

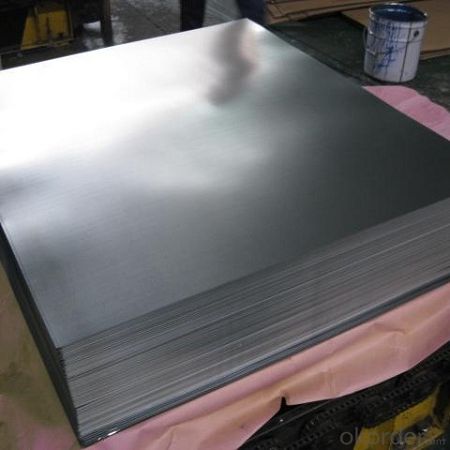

Tinplate Pictures

Tinplate Features

Steel Type: MR, SPCC

Temper(BA& CA): T1- T5, DR8- DR10

Coating: 1.1- 8.4g/m^2

Tickness: 0.15- 0.,50mm

Width: 600-1010mm

I.D: 508mm

Coil weight: 3- 10mt

Passivation: 311

Oiling: DOS

Surface finish: Bright, Stone

Quantity for 20 Feet FCL: 20- 25MT

Package: Seaworthy Export Standard Wooden Pallet

Application

Tinplate is widely used for making all types of containers, electrical machinery parts and many other products

Chemicals and painting cans

Dry food ccans, such as fancy cans, biscuit cans, milk powder cans, tea cans.

Liquid food cans, such as edible oil cans, beverage cans, Tomato paste cans

Sea food cans

Crown corks, easy open ends

Electrical machinery parts

Bakeware and household kitchen parts

Production Standard

GB/T 2520-2000

JIS G3303-2002

DIN EN 10202-2001

ASTM A623M-2002

ISO 11949-1995

- Q: What are the applications of tinplate?

- Tinplate is commonly used in various applications due to its unique properties. It is primarily used in the packaging industry for food and beverage containers, as tin coating provides excellent protection against corrosion and ensures product safety. Tinplate is also utilized in the manufacturing of aerosol cans, paint containers, and metal closures. Its versatility extends to the automotive industry, where it is employed for making fuel tanks, oil filters, and various automotive components. Additionally, tinplate finds applications in the construction sector for roofing, ductwork, and HVAC systems.

- Q: How to distinguish galvanized plate and tin plate

- General galvanized sheet used in home appliances and electronics industry, thicker. Tin plate, tinplate, used in packaging industry, thinner.

- Q: What are the factors that determine the lifespan of tinplate packaging?

- The factors that determine the lifespan of tinplate packaging include the quality of the tin coating, the thickness of the tinplate material, the presence of protective coatings, the storage conditions (e.g., temperature and humidity), exposure to external elements (e.g., moisture, oxygen, and chemicals), and the overall handling and care during transportation and use.

- Q: Can tinplate packaging be used for pet food products?

- Yes, tinplate packaging can be used for pet food products. Tinplate is a suitable material for packaging pet food due to its durability, resistance to corrosion, and ability to maintain the freshness and quality of the food. Additionally, tinplate cans are also safe for pets as they do not leach harmful chemicals into the food.

- Q: What are the advantages of using tinplate for signage?

- There are several advantages of using tinplate for signage. Firstly, tinplate is highly durable and resistant to corrosion, ensuring that the signage can withstand various weather conditions and maintain its quality over time. Additionally, tinplate is lightweight, making it easier to install and transport. It also offers excellent printability, allowing for vibrant and long-lasting graphics on the signage. Moreover, tinplate is a sustainable material as it is 100% recyclable, making it an environmentally friendly choice. Overall, the advantages of using tinplate for signage include durability, corrosion resistance, lightweight nature, excellent printability, and sustainability.

- Q: What are the common challenges in recycling tinplate packaging?

- Some common challenges in recycling tinplate packaging include difficulties in separating tinplate from other materials, contamination from food residue, limited recycling infrastructure, and the high energy requirements for processing tinplate.

- Q: What are the different ways to label tinplate closures?

- There are several different ways to label tinplate closures. One common method is using pressure-sensitive labels that can be applied directly onto the closure. Another option is to use direct printing techniques such as screen printing or pad printing to add the required information onto the closure. Additionally, some closures may be embossed or debossed with branding or text, providing a more permanent labeling solution.

- Q: Can tinplate be formed into complex shapes?

- Yes, tinplate can be formed into complex shapes due to its malleability and ability to be shaped through various forming processes such as deep drawing, embossing, and bending.

- Q: What are the different methods of storing tinplate packaging?

- There are several methods of storing tinplate packaging, including stacking them on shelves or pallets, using storage bins or containers, hanging them on racks or hooks, or utilizing specialized storage systems such as gravity flow or carousel systems. The choice of method depends on factors such as available space, the quantity of packaging, ease of access, and the specific requirements of the packaging material.

- Q: What is the elongation of tinplate?

- The elongation of tinplate refers to its ability to stretch or deform without breaking or cracking under applied stress. It is a measure of the material's ductility and is typically expressed as a percentage increase in length compared to its original length before deformation.

Send your message to us

Tinplate with Prime Quality for Tin Box Making

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords