Tinplate of Prime or Secondary

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

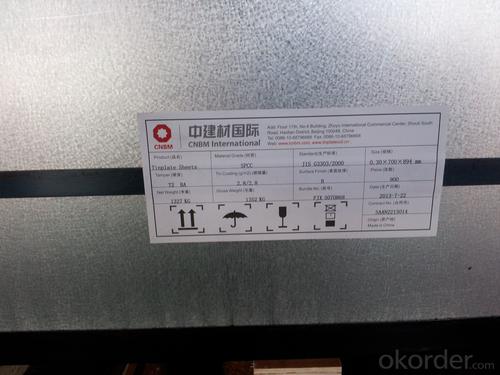

Our Tinplates Specification:

Standard: ISO 11949 -1995, GB/T2520-2000,JIS G3303,ASTM A623, BS EN 10202

Material: MR,SPCC

Thickness:0.15mm - 0.50mm

Width: 600mm -1150mm

Temper: T1-T5; DR8 - DR10;

Annealing: BA & CA

Passivation:311

Oil: DOS

Surface: Finish,bright,stone,matte,silver

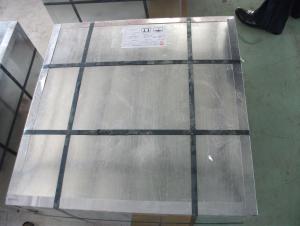

Packing:

1、For sheets: plastic or waterproof paper, metallic cover and angles, steel strips,wooden pallet.

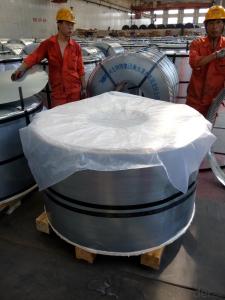

2、For Coils: plastic or waterproof paper,plastic protect plate,steel strips.

Coil Inner Diameter: 508mm

Weight: 6-10 tons/coil

Application: widely used in every kinds of packing cans,such as tea packaging cans, painting packaging cans, chemical packaging cans and dry food packaging cans; and also mechanical parts

Both Prime and Second Quality Are Available!!!

- Q: What are the common applications of tinplate?

- Tinplate is commonly used in various applications such as food packaging, beverage cans, aerosol containers, decorative items, and electrical components.

- Q: What are the advantages of using tinplate?

- There are several advantages of using tinplate. Firstly, tinplate provides excellent protection against corrosion, making it ideal for packaging food and beverages. It also has a high strength-to-weight ratio, making it lightweight yet durable. Additionally, tinplate is easily recyclable, making it a sustainable choice. It can be easily shaped and formed into various designs, making it versatile for packaging purposes. Lastly, tinplate provides a visually appealing and glossy finish, enhancing the overall aesthetic appeal of the product.

- Q: What are the common misconceptions about tinplate packaging?

- One common misconception about tinplate packaging is that it is easily dented or damaged. In reality, tinplate is quite durable and can withstand rough handling without losing its structural integrity. Another misconception is that tinplate packaging is not environmentally friendly. However, tinplate is highly recyclable and can be reused multiple times, making it a sustainable packaging option.

- Q: How is tinplate cut and formed into different shapes?

- Tinplate is commonly cut and formed into different shapes using a variety of methods such as shearing, blanking, stamping, and deep drawing. These processes involve using specialized machinery and tools to cut the tinplate into desired shapes or form it into specific structures.

- Q: Is tinplate resistant to scratches and dents?

- Yes, tinplate is resistant to scratches and dents.

- Q: What are the different printing techniques used on tinplate?

- Some of the different printing techniques used on tinplate include lithography, offset printing, screen printing, and digital printing.

- Q: What are the different printing methods used on tinplate?

- The different printing methods used on tinplate include lithography, offset printing, and silk-screen printing.

- Q: What are the different types of tinplate welding techniques?

- There are primarily two types of tinplate welding techniques: spot welding and seam welding. Spot welding involves the use of electrical resistance to join two tinplate sheets at specific points, while seam welding is a continuous process that creates a continuous weld along the length of the tinplate sheets.

- Q: How does tinplate perform in terms of tamper resistance?

- Tinplate performs well in terms of tamper resistance due to its strong and durable nature. It is difficult to manipulate or tamper with, providing a secure packaging solution for various products.

- Q: What are the different closure mechanisms for tinplate cans?

- There are several closure mechanisms used for tinplate cans, including the traditional double seam closure, snap-on lids, twist-off caps, and easy-open ends.

Send your message to us

Tinplate of Prime or Secondary

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords