Electrolytic Tinplate Coils of High Quality for Metal Container 0.19mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Electrolytic Tinplate Coils of High Quality for Metal Container 0.19mm Description

Electrolytic Tinplate is a thin steel sheet coated by tin. It has an extremely beautiful metallic luster as well as excellent properties in corrosion resistance, solder ability, and weld ability.

2.Main Features of the Electrolytic Tinplate Coils of High Quality for Metal Container 0.19mm

Tinplate is widely used for making all types of containers such as food cans, beverage cans, and artistic cans, tea cans, painting cans, chemical package cans and dry food package cans, metal printing etc. Its applications are not limited to containers; recently, tinplate has also been used for making electrical machinery parts and many other products.

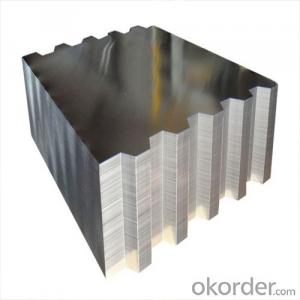

3.Electrolytic Tinplate Coils of High Quality for Metal Container 0.19mm Images

4.Electrolytic Tinplate Coils of High Quality for Metal Container 0.19mm Specification

Standard:BS EN 10202

Material: SPCC

Thickness:0.19mm

Width:736mm

Temper: T2

Annealing: BA

Coil Inner Diameter: 508mm

Weight: 6-10 tons/coil

Passivation:311

Oil: DOS

Surface: silver

5.FAQ of Electrolytic Tinplate Coils of High Quality for Metal Container 0.19mm

- What is your producation capacity per month?

We can produce about 25,000tons

- What is tinning and how does it work?

Tinning is the process of thinly coating sheets of wrought iron or steel with tin, and the resulting product is known as tinplate. It is most often used to prevent rust.

- Do you only have prime quality tinplate?

We can supply both prime and second quality tinplate.

- Q: What material is the tin plate, please?

- Popularly speaking, it was tin plated on the surface of the iron sheet, just because it was imported by Macao at that time, so it always called "tinplate iron"

- Q: What are the typical cost considerations for tinplate packaging?

- The typical cost considerations for tinplate packaging include the cost of raw materials, manufacturing and labor costs, production volume, design complexity, customization requirements, transportation costs, and any additional finishing or coating expenses.

- Q: Can tinplate be used for medical packaging?

- Yes, tinplate can be used for medical packaging. Tinplate is a durable and corrosion-resistant material, making it suitable for protecting and preserving medical products. It meets the necessary hygiene and safety standards required for medical packaging and can provide an effective barrier against moisture, light, and oxygen. Additionally, tinplate is recyclable, making it an environmentally friendly choice for medical packaging.

- Q: What are the weight advantages of using tinplate?

- One of the weight advantages of using tinplate is its lightweight nature. Tinplate is made by coating a thin layer of tin onto a steel substrate, resulting in a material that is significantly lighter than other packaging options such as glass or aluminum. This lightweight characteristic makes tinplate an ideal choice for various industries, including food and beverage, where weight reduction is essential for transportation, storage, and overall product cost efficiency.

- Q: Can tinplate be used for packaging frozen food?

- Yes, tinplate can be used for packaging frozen food. Tinplate is a type of steel coated with a thin layer of tin, which provides excellent protection against moisture and oxygen. This makes it an ideal material for packaging frozen food as it helps to preserve the quality and freshness of the product. Additionally, tinplate is also resistant to extreme temperatures, ensuring the integrity of the packaging even in freezing conditions.

- Q: How to test the tightness of tin metal cans?

- The empty tank which has been cleaned can be dried by 35, and the pressure or pressure leak test shall be carried out according to the equipment condition of each unit. B.1 pressure leak test, the empty tank will be carefully injected into the water until eight or nine into full, the rubber ring will be placed in the appropriate plexiglass plate at the opening side of the roll, so that it can be sealed. Start the vacuum pump, turn off the bleeder valve, hold down the cover by hand, control the pumping, and make the vacuum gauge rise from 0Pa to 6.8X10 PA (510mmHg) for more than 1min, and keep the vacuum above 1min.

- Q: How is tinplate different from other types of steel?

- Tinplate is different from other types of steel due to its unique coating of tin on both sides, which provides corrosion resistance, enhances the material's appearance, and makes it suitable for packaging applications.

- Q: How is tinplate used in the beverage industry?

- Tinplate is commonly used in the beverage industry for packaging cans due to its ability to provide a protective barrier against corrosion and maintain the flavor and quality of the beverages.

- Q: How does the thickness of tinplate affect its strength and durability?

- The thickness of tinplate directly influences its strength and durability. Generally, thicker tinplate tends to be stronger and more durable compared to thinner tinplate. A thicker tinplate has a higher resistance to bending, denting, or puncturing, making it less prone to damage during handling, storage, or transportation. Additionally, the increased thickness provides better protection against corrosion and extends the tinplate's lifespan. However, thicker tinplate also tends to be heavier and more expensive. Therefore, finding the right balance between thickness and cost is crucial when considering the strength and durability requirements for a specific application.

- Q: What are the differences in the corrosion behavior of two ferrous iron products?

- There are other statements, such as China used this lamp tin plate made of kerosene, shaped like a horse, so called "tin".

Send your message to us

Electrolytic Tinplate Coils of High Quality for Metal Container 0.19mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords