Tin Plate Price for Enameled Food Tinplate

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Tin Plate Price for Enameled Food Tinplate Description

1) MR BASE MATERIALS FROM POSCO/BAOSTEEL

2) END USE:MILK/BEVERAGE CANS

3)Temper: T1- T5,DR7~DR9

Tinplate is sheet steel covered by a layer of tin, widely used in packaging industry and other field.

We supply reasonable prices of tinplate with better quality and faster delivery. We hope to conclude business with more customers at home and abroad.

2. Main Features of the Tin Plate Price for Enameled Food Tinplate

Tinplate in primarily used for packaging food stuffs and beverages, also used in containers for oils, grease, paints, polishes, chemicals and many other products. Aerosol containers and caps and closures are also made from ETP.

Tinplate is a thin steel coil coated by tin. It has an extremely beautiful metallic luster as well as excellent properties in corrosion resistance, solderability and weldability. Electrolytic Tinplate undoubtedly enjoys the pride of place as a packaging medium especially for food. The free tin layer is not only responsible for the attractive bright finish and ease of solderability but is also non-toxic a factor of vital importance in food packaging.

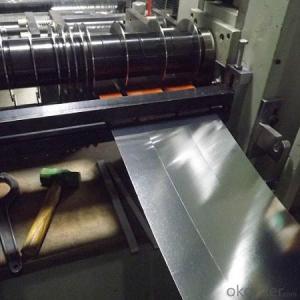

3. Tin Plate Price for Enameled Food Tinplate Images

4.Tin Plate Price for Enameled Food Tinplate Specification

Product name | Prime T3 Tinplate in sheets |

Steel Type | SPCC, MR |

Temper(BA&CA) | T1~T5 |

Coating for the Prime T3 Tinplate in sheets | 1.1~11.2g/m2 |

Thickness and tolerance | 0.15~0.50mm(Tolerance: _+0.01 mm) |

Width & tolerance | 300~1000mm (Tolerance: 0~3mm) |

Cut length & tolerance | 450~``50mm (Tolerance: 0~3mm ) |

Coil inside diameter | 420/508mm |

Coil Weight | Prime T3 Tinplate in sheets weight 3~10 MT |

Passivation | 311 |

Oiling | DOS |

Surface Finish | Bright, Stone, Silver, Matte |

Packaging | Prime T3 Tinplate in sheets with Seaworthy Standard with wooden pallet |

Standards Available | GB/T2520, JIS G3303, ASTM A623M & EN10202 |

5.FAQ of Tin Plate Price for Enameled Food Tinplate

How can I buy the products in my country?

Please send us an inquiry or email,we will reply to you if there is distributor in your country.

- Q: How is tinplate used in the manufacturing of electronic devices?

- Tinplate is commonly used in the manufacturing of electronic devices as it provides an ideal material for the production of casing and outer components. Its corrosion-resistant properties help protect the internal circuitry from environmental factors, ensuring durability and longevity of the electronic device. Additionally, tinplate's malleability allows for easy shaping and customization, enabling manufacturers to create sleek and aesthetically pleasing designs.

- Q: Can tinplate be used for promotional or gift packaging?

- Yes, tinplate can be used for promotional or gift packaging. Tinplate is a versatile material that is durable, visually appealing, and can be easily customized with various designs. It offers a premium look and feel, making it an excellent choice for creating attractive promotional or gift packaging that can leave a lasting impression on recipients.

- Q: Can tinplate be used for medical packaging?

- Yes, tinplate can be used for medical packaging. It is a commonly used material for packaging medical products due to its durability, resistance to corrosion, and ability to maintain product quality. Tinplate containers can provide a protective barrier against moisture, light, and oxygen, ensuring the safety and integrity of medical supplies.

- Q: How does tinplate contribute to the circular economy?

- Tinplate contributes to the circular economy by being highly recyclable and reusable. It can be easily collected, sorted, and processed into new products without losing its quality. This reduces the need for virgin materials and saves energy and resources in the production process. Additionally, tinplate's corrosion resistance properties extend the lifespan of products, further minimizing waste and promoting a more sustainable approach to manufacturing.

- Q: How does tinplate contribute to the attractiveness of cosmetic packaging?

- Tinplate contributes to the attractiveness of cosmetic packaging by providing a sleek and shiny appearance. It adds a touch of elegance and sophistication to the packaging, making it visually appealing and enticing to consumers. The use of tinplate also allows for creative and intricate designs to be printed on the packaging, enhancing its overall aesthetic appeal. Additionally, tinplate's durability and resistance to corrosion ensure that the packaging remains in pristine condition, further enhancing the attractiveness of cosmetic products.

- Q: What are the main factors influencing the competitiveness of tinplate manufacturers?

- The main factors influencing the competitiveness of tinplate manufacturers include the cost of raw materials, market demand and competition, technological advancements, production efficiency, quality control, geographic location, and sustainability practices. Additionally, factors like government regulations, trade policies, and customer preferences also play a significant role in determining the competitiveness of tinplate manufacturers.

- Q: What are the main trends in tinplate recycling?

- The main trends in tinplate recycling include increased awareness and implementation of recycling programs, advancements in technology for efficient separation and processing of tinplate, and the growing demand for sustainable packaging solutions. Additionally, there has been a shift towards closed-loop recycling systems, where tinplate waste is recycled and used to produce new tinplate products, reducing the need for virgin materials.

- Q: Why tin tin plating?

- In nature, tin is seldom free, so there are few pure metallic tin. The most important tin ore is cassiterite, chemical composition of two tin oxide. This copper smelting tin, iron, aluminum is easy, as long as the cassiterite together with burning charcoal, charcoal will be put out in cassiterite tin reduction. Obviously, the ancient people tin place if there is fire burning when grilled wild animals, the earth would be charcoal reduction of cassiterite, tin silver and melted will flow out. Because of this, tin was discovered long ago.

- Q: What are the common labeling options for tinplate containers?

- The common labeling options for tinplate containers include adhesive labels, shrink sleeves, direct printing, and lithographic printing.

- Q: Can tinplate be used for consumer electronics packaging?

- Yes, tinplate can be used for consumer electronics packaging. Tinplate is a durable and corrosion-resistant material that provides excellent protection for electronic devices. It is commonly used for packaging consumer electronics such as smartphones, tablets, and small appliances.

Send your message to us

Tin Plate Price for Enameled Food Tinplate

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords