Electrolytic Tinplate for Crown Caps Tinplate China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Electrolytic Tinplate for Crown Caps Tinplate China Description

Tinplate is sheet steel covered by a layer of tin, widely used in packaging industry and other field.

2. Main Features of the Electrolytic Tinplate for Crown Caps Tinplate China

Tinplate in primarily used for packaging food stuffs and beverages, also used in containers for oils, grease, paints, polishes, chemicals and many other products. Aerosol containers and caps and closures are also made from ETP

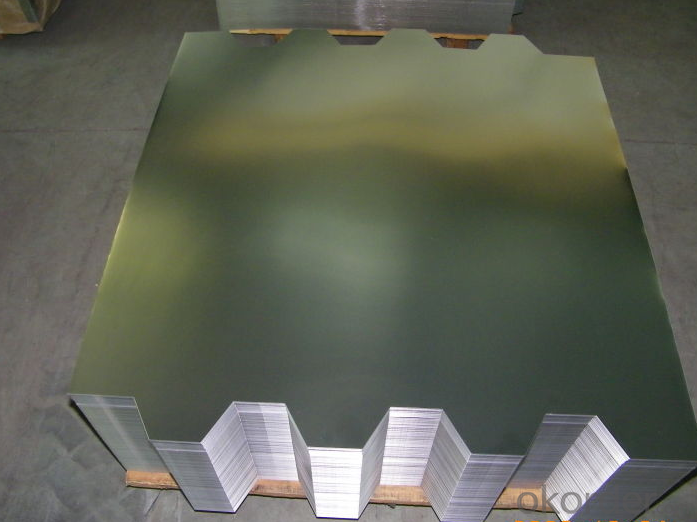

3. Electrolytic Tinplate for Crown Caps Tinplate China Images

4.Electrolytic Tinplate for Crown Caps Tinplate China Specification

Product name | Prime T3 Tinplate in sheets |

Steel Type | SPCC, MR |

Temper(BA&CA) | T1~T5 |

Coating for the Prime T3 Tinplate in sheets | 1.1~11.2g/m2 |

Thickness and tolerance | 0.15~0.50mm(Tolerance: _+0.01 mm) |

Width & tolerance | 300~1000mm (Tolerance: 0~3mm) |

Cut length & tolerance | 450~``50mm (Tolerance: 0~3mm ) |

Coil inside diameter | 420/508mm |

Coil Weight | Prime T3 Tinplate in sheets weight 3~10 MT |

Passivation | 311 |

Oiling | DOS |

Surface Finish | Bright, Stone, Silver, Matte |

Packaging | Prime T3 Tinplate in sheets with Seaworthy Standard with wooden pallet |

Standards Available | GB/T2520, JIS G3303, ASTM A623M & EN10202 |

5.FAQ of Electrolytic Tinplate for Crown Caps Tinplate China

How long does it take to get the product if i place an order?

With the process of your requirements,we will pack and deliver in 3-7 days.If it is by sea shipment,it will take 15-45 days depending on different locations.

- Q: How does tinplate perform in terms of lightness and portability?

- Tinplate performs well in terms of lightness and portability. It is a lightweight material that is easy to carry and transport, making it convenient for various applications.

- Q: What are the typical manufacturing processes for tinplate products?

- The typical manufacturing processes for tinplate products include coil preparation, coil cleaning, annealing, coating, temper rolling, cutting, and forming.

- Q: How does tinplate packaging impact brand image and perception?

- Tinplate packaging can have a positive impact on brand image and perception. It is often associated with high quality and premium products, which can enhance the perceived value of the brand. Tinplate packaging also offers a luxurious and retro charm, appealing to consumers who value aesthetics and nostalgia. Additionally, tinplate packaging can provide better protection for products, ensuring their freshness and quality, which further enhances the brand's reputation. Overall, tinplate packaging can contribute to a positive brand image and create a favorable perception among consumers.

- Q: What is the use of tinplate printing tin, storage of food safety

- Electrophoresis on a layer of special coating with food packaging, the packaging is extremely tight, in order to packaging material appearance, appearance are printed with various patterns, because it is the coating of food grade materials, so the food packaging is safe in the warranty period.

- Q: Can tinplate be used for packaging of corrosive substances?

- No, tinplate is not suitable for packaging corrosive substances as it can react with the corrosive materials and corrode, leading to potential contamination and compromised packaging integrity.

- Q: Can tinplate be used for packaging pet care products?

- Yes, tinplate can be used for packaging pet care products. Tinplate is a durable and lightweight material that provides good protection against moisture, ensuring the quality and safety of pet care products. Additionally, tinplate can be easily shaped and decorated, making it an ideal choice for attractive and functional packaging.

- Q: What are the common closure mechanisms for tinplate containers?

- The common closure mechanisms for tinplate containers include screw-on lids, snap-on lids, and press-on lids.

- Q: Can tinplate packaging be used for aerosol products?

- Yes, tinplate packaging can be used for aerosol products. Tinplate is a commonly used material in aerosol can production due to its durability, resistance to corrosion, and ability to withstand the pressure exerted by aerosol content. Additionally, tinplate cans can be easily shaped and decorated, making them suitable for various aerosol products in the market.

- Q: What are the main applications of tinplate in the pet food industry?

- Tinplate is commonly used in the pet food industry for packaging purposes. It offers excellent protection against oxygen, light, and moisture, which helps to maintain the freshness and quality of pet food. Additionally, tinplate cans are easy to open and reseal, making them convenient for pet owners. The material is also recyclable, making it an environmentally friendly choice for packaging.

- Q: How do you paint the tinplate?

- Spray paint. The zygote to be painted is placed on a shelf or plane or hung up and sprayed with a spray gun. Use a small air compressor and spray gun

Send your message to us

Electrolytic Tinplate for Crown Caps Tinplate China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords