Tinplate ETP OF Prime or Secondary Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Our Tinplates Specification:

Standard: ISO 11949 -1995, GB/T2520-2000,JIS G3303,ASTM A623, BS EN 10202

Material: MR,SPCC

Thickness:0.15mm - 0.50mm

Width: 600mm -1150mm

Temper: T1-T5; DR8 - DR10;

Annealing: BA & CA

Passivation:311

Oil: DOS

Surface: Finish,bright,stone,matte,silver

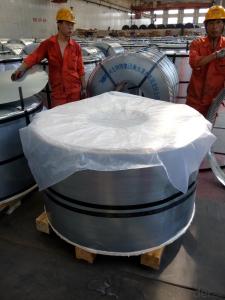

Packing:

1、For sheets: plastic or waterproof paper, metallic cover and angles, steel strips,wooden pallet.

2、For Coils: plastic or waterproof paper,plastic protect plate,steel strips.

Coil Inner Diameter: 508mm

Weight: 6-10 tons/coil

Application: widely used in every kinds of packing cans,such as tea packaging cans, painting packaging cans, chemical packaging cans and dry food packaging cans; and also mechanical parts

Both Prime and Second Quality Are Available!!!

- Q: What are the different ways to open tinplate cans?

- There are several ways to open tinplate cans, including using a can opener, a knife, a spoon, or even your hands if the can has a pull tab.

- Q: Can tinplate be customized with different designs or logos?

- Yes, tinplate can be customized with different designs or logos. It is a versatile material that can be decorated using various printing techniques such as lithography, offset printing, or embossing. This allows for the creation of unique and personalized designs on tinplate, making it suitable for branding and promotional purposes.

- Q: What are the common surface finishes for tinplate?

- The common surface finishes for tinplate include bright, stone, silver, and matte finishes.

- Q: What are the environmental impacts of producing tinplate?

- The production of tinplate has several environmental impacts. The extraction and processing of tin ore can result in habitat destruction, deforestation, and soil erosion. The smelting process emits greenhouse gases, contributing to climate change. Additionally, the use of chemicals during production can contaminate water sources and harm aquatic life. Proper waste management and adopting more sustainable practices can help mitigate these impacts.

- Q: How is tinplate coated for cosmetic packaging?

- Tinplate is typically coated for cosmetic packaging through a process called electrolytic tin plating. This involves immersing the tinplate in a bath containing a tin salt solution and passing an electric current through it. As a result, a layer of tin is deposited onto the surface of the tinplate, providing a protective coating that prevents corrosion and enhances the overall aesthetics of the packaging.

- Q: What is the average lifespan of tinplate packaging?

- The average lifespan of tinplate packaging depends on various factors such as usage, storage conditions, and handling. However, tinplate packaging is known for its durability and longevity, and with proper care, it can last for several years or even decades.

- Q: How does tinplate contribute to the sterility of medical equipment?

- Tinplate contributes to the sterility of medical equipment by providing a protective barrier that prevents the growth of bacteria and other microorganisms. The tin coating on the steel surface of the tinplate acts as a barrier against moisture and oxygen, preventing rusting and corrosion. This not only maintains the integrity of the equipment but also ensures that no contaminants are introduced into the medical environment. Additionally, tinplate is easy to clean and sterilize, further enhancing its contribution to the sterility of medical equipment.

- Q: How does tinplate packaging handle exposure to different chemicals?

- Tinplate packaging is highly resistant to exposure to different chemicals, making it a reliable choice for packaging various products. Its non-reactive nature ensures that it does not contaminate or react with the contents inside, maintaining the product's quality and safety. Additionally, tinplate packaging is often coated with a protective layer, such as lacquer or enamel, further enhancing its resistance to chemical exposure. Overall, tinplate packaging proves to be a durable and dependable option when it comes to handling different chemicals.

- Q: How does tinplate impact the ease of opening and closing packaging?

- Tinplate can greatly impact the ease of opening and closing packaging due to its durability and malleability. It provides a sturdy and rigid structure to packaging, ensuring that it maintains its shape and integrity, making it easier to open and close repeatedly without any damage or distortion. Additionally, tinplate's smooth surface allows for effortless sliding and gliding when opening or closing packaging, further enhancing the overall user experience.

- Q: How does tinplate compare to other packaging materials in terms of shelf appeal?

- Tinplate stands out among other packaging materials in terms of shelf appeal due to its unique metallic appearance, which adds a sense of premium quality and attractiveness to the product. Its high gloss finish and ability to be printed with vibrant colors and intricate designs make it visually appealing, catching the attention of consumers and stimulating their interest. Additionally, tinplate offers excellent durability and protection, ensuring that the product remains in pristine condition on the shelf, further enhancing its shelf appeal.

Send your message to us

Tinplate ETP OF Prime or Secondary Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords