Tin Plate Coils and Sheets for Chemical Can Making

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Electrolytic Tin Plate for Chemical Metal Packaging Description

Due to Tinplate packaging`s good seal, nature, dark, robustness and unique decorative metal charm, it has a wide range of coverage in the packaging container industry,and common international packaging varieties. With a variety of CC tinplate material, DR materials, chrome plated and constantly enrich and promotion and development of packaging products and technology, tinplate packaging has promoted with innovation.

Because of its strong antioxidant and diverse styles, beautifully printed, tinplate containers are very popular and loved by customers, and they are widely used in food packaging, pharmaceutical packaging, commodity packaging, instrumentation, packaging, industrial packaging and so on.

With the continuous improvement of tinplate printing technology and processing technology, tinplate packaging has developed more widely.

2.Main Features of the Electrolytic Tin Plate Coils and Sheets for Metal Packaging

Appearance – Electrolytic Tin Plate is characterized by its beautiful metallic luster. Products with various kinds of surface roughness are produced by selecting the surface finish of the substrate steel sheet.

Paintability and printability – Electrolytic Tin Plates have excellent paintability and printability. Printing is beautifully finished using various lacquers and inks.

Formability and strength – Electrolytic Tin Plates have got very good formability and strength. By selecting a proper temper grade, appropriate formability is obtained for different applications as well as the required strength after forming.

Hygienic – Tin coating provides good and non toxic barrier properties to protect food products from impurities, bacteria, moisture, light and odours.

Safe – Tinplate being low weight and high strength makes food cans easy to ship and transport.

Eco friendly – Tinplate offers 100 % recyclability.

Tin is not good for low temperature applications since it changes structure and loses adhesion when exposed to temperatures below – 40 deg C.

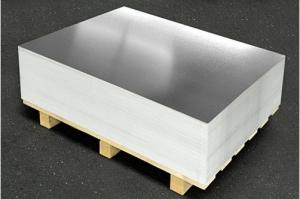

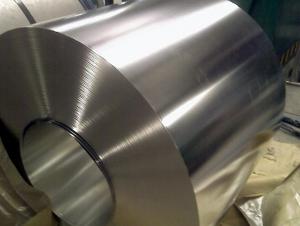

3.Electrolytic Tin Plate Coils and Sheets for Metal Packaging Images

4.Electrolytic Tin Plate Coils and Sheets for Metal Packaging Specification

Standard | ISO 11949 -1995, GB/T2520-2000,JIS G3303,ASTM A623, BS EN 10202

|

Material | MR,SPCC |

Thickness | 0.15mm - 0.50mm |

Width | 600mm -1150mm |

Temper | T1-T5 |

Annealing | BA & CA |

Coil Inner Diameter | 508mm |

Weight | 6-10 tons/coil 1~1.7 tons/sheets bundle |

Passivation | 311 |

Oil | DOS |

Surface | Finish,bright,stone,matte,silver |

5.FAQ of Electrolytic Tin Plate Coils and Sheets for Metal Packaging

-What your tinplate material is used for ?

Tinplate is widely used for the packaging of products. Such as food cans,

beverage cans, pet cans, closures, general line cans and so on.

Printed Tinplate is offered!!

-How to place .an order or contact you ?

Please send us Email. we will give you a quick response in seconds .

- How is your quality ?

All our quality is prime even the secondary quality . We have many years experience

In this field with serious quality control standard . Advanced equipment, We welcome your visit to our factory .

- Q: What are the challenges faced in the recycling of tinplate?

- One of the main challenges in the recycling of tinplate is the separation of tin from steel. Tin is a valuable material and it is important to recover it efficiently. However, the process of separating tin from steel can be complicated and time-consuming. Additionally, the presence of other contaminants in tinplate, such as paint or other coatings, can further complicate the recycling process. Another challenge is the collection and sorting of tinplate waste, as it often ends up mixed with other materials in the general waste stream. This makes it harder to recover and recycle tinplate efficiently. Overall, the challenges in the recycling of tinplate involve the efficient separation of tin from steel and the collection and sorting of tinplate waste.

- Q: How does tinplate contribute to the durability of stationery products?

- Tinplate contributes to the durability of stationery products by providing a protective and corrosion-resistant coating. This coating helps to prevent moisture and other environmental factors from damaging the stationery items, ensuring they have a longer lifespan and remain in good condition for a longer period of time. Additionally, the strength and rigidity of tinplate make it resistant to bending or warping, further enhancing the durability of stationery products.

- Q: Can tinplate be used for marine applications?

- Yes, tinplate can be used for marine applications. Tinplate is known for its excellent corrosion resistance, making it a suitable material for marine environments where exposure to saltwater and moisture is a concern. Additionally, tinplate's strength and durability make it ideal for various marine applications such as packaging, containers, and components for boats and ships.

- Q: What are the different ways to seal tinplate containers?

- There are several different ways to seal tinplate containers, including using a screw-on cap, a snap-on lid, a crimped or rolled edge, a heat-sealed liner, or a combination of these methods.

- Q: How can tinplate be identified?

- The quality of tinplate is related to the final use.

- Q: What is the purpose of tin coating on tinplate?

- The purpose of tin coating on tinplate is to prevent corrosion and enhance the durability of the underlying steel substrate.

- Q: How does tinplate perform in high humidity environments?

- Tinplate performs well in high humidity environments due to its corrosion resistance properties. The tin coating on the steel substrate acts as a barrier, preventing moisture from reaching the metal surface and causing corrosion. Therefore, tinplate is an excellent choice for packaging and other applications in high humidity conditions.

- Q: Can tinplate be used in extreme temperatures?

- Yes, tinplate can be used in extreme temperatures. Tinplate is known for its excellent heat resistance properties, making it suitable for applications in extreme temperatures. The tin coating on the steel substrate provides protection against corrosion and helps maintain the structural integrity of the tinplate even in high or low temperature environments.

- Q: Can tinplate be embossed or engraved?

- Yes, tinplate can be embossed or engraved.

- Q: What are the differences in the corrosion behavior of two ferrous iron products?

- The name "tinplate" is not exact. Therefore, in 1973, when the Chinese tin plate meeting was called "tinplate", the official document no longer used the name "tinplate".

Send your message to us

Tin Plate Coils and Sheets for Chemical Can Making

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords