Electrolytic Tinplate Coil / Sheets for Foods Can Packaging

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 7000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Electrolytic Tin Plate Coils and Sheets for Foods Metal Packaging Description

Due to Tinplate packaging`s good seal, nature, dark, robustness and unique decorative metal charm, it has a wide range of coverage in the packaging container industry,and common international packaging varieties. With a variety of CC tinplate material, DR materials, chrome plated and constantly enrich and promotion and development of packaging products and technology, tinplate packaging has promoted with innovation.

Because of its strong antioxidant and diverse styles, beautifully printed, tinplate containers are very popular and loved by customers, and they are widely used in food packaging, pharmaceutical packaging, commodity packaging, instrumentation, packaging, industrial packaging and so on.

With the continuous improvement of tinplate printing technology and processing technology, tinplate packaging has developed more widely.

2.Main Features of the Electrolytic Tin Plate Coils and Sheets for Foods Metal Packaging

Appearance – Electrolytic Tin Plate is characterized by its beautiful metallic luster. Products with various kinds of surface roughness are produced by selecting the surface finish of the substrate steel sheet.

Paintability and printability – Electrolytic Tin Plates have excellent paintability and printability. Printing is beautifully finished using various lacquers and inks.

Formability and strength – Electrolytic Tin Plates have got very good formability and strength. By selecting a proper temper grade, appropriate formability is obtained for different applications as well as the required strength after forming.

Corrosion resistance – Tinplate has got good corrosion resistance. By selecting a proper coating weight, appropriate corrosion resistance is obtained against container contents. Coated items should meet 24 hour 5 % salt spray requirement.

Solderability and weldability – Electrolytic Tin Plates can be joined both by soldering or welding. These properties of tinplate are used for making various types of cans.

Hygienic – Tin coating provides good and non toxic barrier properties to protect food products from impurities, bacteria, moisture, light and odours.

Safe – Tinplate being low weight and high strength makes food cans easy to ship and transport.

Eco friendly – Tinplate offers 100 % recyclability.

Tin is not good for low temperature applications since it changes structure and loses adhesion when exposed to temperatures below – 40 deg C.

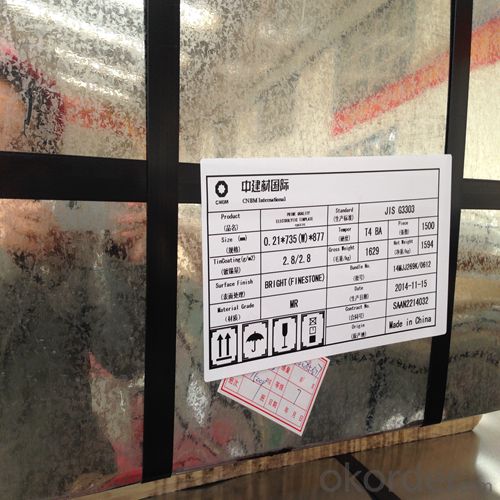

3.Electrolytic Tin Plate Coils and Sheets for Foods Metal Packaging Images

4.Electrolytic Tin Plate Coils and Sheets for Foods Metal Packaging Specification

Standard | ISO 11949 -1995, GB/T2520-2000,JIS G3303,ASTM A623, BS EN 10202

|

Material | MR,SPCC |

Thickness | 0.15mm - 0.50mm |

Width | 600mm -1150mm |

Temper | T1-T5 |

Annealing | BA & CA |

Coil Inner Diameter | 508mm |

Weight | 6-10 tons/coil 1~1.7 tons/sheets bundle |

Passivation | 311 |

Oil | DOS |

Surface | Finish,bright,stone,matte,silver |

5.FAQ of Electrolytic Tin Plate Coils and Sheets for Foods Metal Packaging

- How are the Electrolytic Tin Plates specified?

The Electrolytic Tin Plates are specified as per the steel base, extent of tempering, the coating weight, annealing method and the surface finish.

- How many types there are for base steels?

The base steels are of three types: Type MR, L, D

- Q: What are the different types of tin coatings used on tinplate?

- There are primarily three types of tin coatings used on tinplate: electrolytic tinplate (ETP), black plate, and tin-free steel (TFS). ETP is the most common type and provides excellent corrosion resistance and solderability. Black plate is uncoated tinplate, often used for industrial applications or as a base for other coatings. TFS, on the other hand, replaces the tin coating with a thin layer of chromium or chromium oxide, offering similar corrosion resistance but without the use of tin.

- Q: What are the advantages of using tinplate?

- There are several advantages of using tinplate. Firstly, tinplate is highly durable and resistant to corrosion, making it ideal for packaging and storage purposes. Additionally, tinplate is lightweight and easily formable, allowing for versatility in design and easy transportation. It also provides a high level of protection to the contents, preventing spoilage or contamination. Moreover, tinplate is recyclable and environmentally friendly, contributing to sustainability efforts. Lastly, tinplate has excellent printability, allowing for attractive and eye-catching designs, enhancing product visibility and branding.

- Q: What are the challenges faced in the recycling of tinplate?

- One of the main challenges in the recycling of tinplate is the separation of tin from the steel base. Tinplate consists of a thin layer of tin coated on steel, and separating these materials requires specialized equipment and processes. Additionally, the presence of other contaminants, such as paint or coatings, can further complicate the recycling process. Proper sorting and cleaning of tinplate waste is necessary to ensure efficient recycling and minimize the loss of valuable materials.

- Q: What are the benefits of using tinplate for paint cans?

- Tinplate offers numerous benefits for paint cans, including its excellent durability, resistance to corrosion, and ability to maintain product quality by providing a protective barrier. Additionally, tinplate is recyclable, making it a sustainable choice for packaging.

- Q: Can tinplate be used for paint can packaging?

- Yes, tinplate can be used for paint can packaging. Tinplate is a widely used material for packaging due to its durability and ability to protect the contents from external factors. It is commonly used for paint can packaging as it provides a strong barrier against moisture and corrosion, ensuring the paint remains in good condition. Additionally, tinplate is easily recyclable, making it an environmentally friendly choice for packaging.

- Q: What's the head iron?

- The name "tinplate", also known as tin plated iron, is the common name for tin plated steel sheet. The English abbreviation for "SPTE" refers to cold-rolled low carbon steel sheet or strip coated with commercially pure tin on both sides. Tin plays a major role in preventing corrosion and rusting. It will be the steel strength and formability and corrosion resistance of tin soldering, and beautiful appearance with a material, corrosion resistant, non-toxic, high strength and good ductility properties.

- Q: 0.25mm which melting point is low in tin plate and tin plate?

- Tin plated steel sheet and strip, also known as tinplate, the steel plate (belt) surface tin plated, has good corrosion resistance, non-toxic, can be used as packaging material cans, inside and outside the cable sheath, telecommunications instrument parts, flashlight and other hardware.

- Q: What are the limitations of using tinplate?

- One limitation of using tinplate is its susceptibility to corrosion. Tinplate can easily rust when exposed to moisture or acidic environments, making it less durable and suitable for long-term use. Additionally, tinplate is relatively heavy compared to other packaging materials, which can increase transportation costs. Lastly, tinplate is not as malleable as other metals, making it less flexible for certain manufacturing processes.

- Q: What are the common industry standards for tinplate?

- The common industry standards for tinplate include specifications for the thickness, temper, coating weight, and surface finish. Additionally, the standards outline requirements for the mechanical properties, such as elongation and hardness, as well as the chemical composition of the tin coating. These standards ensure consistent quality and compatibility across different manufacturers and applications in the tinplate industry.

- Q: How does tinplate compare to other packaging materials in terms of shelf appeal?

- Tinplate stands out among other packaging materials in terms of shelf appeal due to its unique metallic appearance and durability. Its glossy finish and reflective properties attract attention and enhance the visual appeal of products on store shelves. Additionally, tinplate can be easily customized with vibrant colors, intricate designs, and embossing, making it an excellent choice for brands looking to create eye-catching packaging. Overall, tinplate offers a visually appealing and premium look that sets it apart from other packaging materials.

Send your message to us

Electrolytic Tinplate Coil / Sheets for Foods Can Packaging

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 7000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords