Tight Fabric Cone Bobbin Winder Machinery for Textile

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Application:

Tight Fabric Cone Bobbin Winder Machinery for Textile is suitable for winding yarns on cones with even density and soft package before dyeing.

Main features:

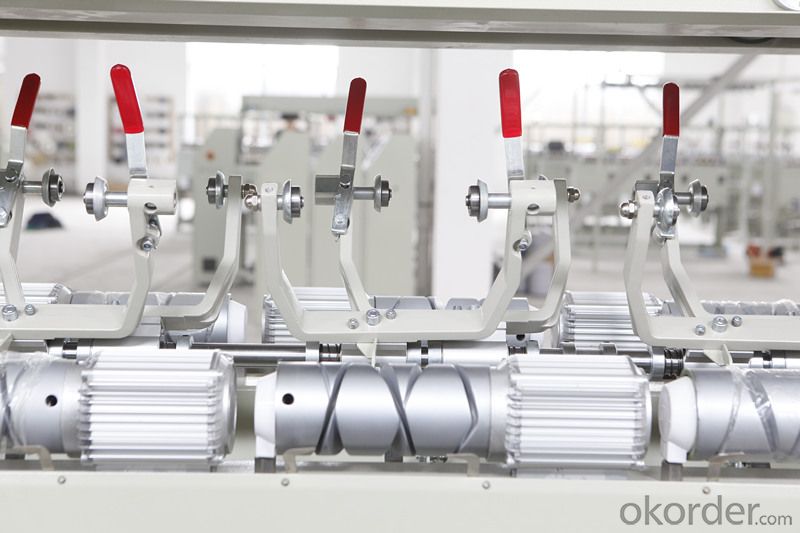

Tight Fabric Cone Bobbin Winder Machinery for Textile

1. Vertical yarn path design, no inflection point, yarn friction is small, less hairiness.

2. Special motor with longer axis can prevent yarn twisting, speed controlled by inverter.

3. Double points tension control system with micro motors, uniform yarn tension.

4. Using high quality alloy drums with optimized groove shape, which has the advantages of good anti-overlapping characteristics, light weight, good wear resistance, and static elimination.

5. Single winding motor control for each spindle, electronic length, single spindle automatic stop while yarn breaking or fully filled.

6. High-speed creel with gas spring, which can keep constant winding pressure. This creel is stable and reliable.

7. The traverse device for making the soft edge is very easy to adjust, that will make the loose bobbin be suitable for even dyeing.

8. There is tube conveyor on the machine, it can convey tubes and packing automatically. With it, you can not only save labor, but also keep the production site clean.

9. Our adjustable block yarn sheet metal can prevent the yarn be a mass.

Product pictures of Tight Fabric Cone Bobbin Winder Machinery for Textile:

Delivery Pictures:

Specification:

Tight Fabric Cone Bobbin Winder Machinery for Textile

| Items | Technical parameters |

| Types of winding | Drum,Random |

| Mechanical speed | Up to 800m/min |

| Package shape | Cylindrical or conical |

| Traverse length | 230mm,280mm, |

| Package bobbin | Cylindrical or conical of 3°30’ |

| package diameter | Up toφ 290 mm |

| Package density | 0.2-0.4g/cm3 |

| Package weight | Up to10kg |

FAQ of Tight Fabric Cone Bobbin Winder Machinery for Textile:

· Q:What is the machine used for?

A: Tight Fabric Cone Bobbin Winder Machinery for Textile is suitable for processing PP, PE split film yarn/ just twine, cotton twine, weaved twine to ball.

· Q: What is the MOQ?

A: 1 set.

· Q: What is the lead time of the product?

A: 5-20 days after payment

- Q: How does the mechanical wave generated in the spinning process work?

- Mechanical waves meet, you can cross each other, do not interfere with each other

- Q: The state of the textile industry machinery revitalization, expanding domestic demand, the specific policy is what?

- State textile machinery industry after decades of development, has made great progress. But compared with the world's advanced technology, there are still some gaps and some more serious problems. The overall technical level of textile machinery is low, product independent development and innovation ability is weak, lack of research and development funds. Enterprise technical reform is not enough, manufacturing technology behind

- Q: What is the current status of the textile industry?

- China is the textile production and export power, China's textile industry itself after years of development, competitive advantage is very obvious, with the world's most complete industrial chain, the highest level of processing support, many developed industrial clusters to deal with market risk self-regulation The ability to continuously enhance the industry to maintain a steady pace of development provides a solid guarantee.

- Q: What is the difference between yarn spinning and ring spinning?

- Ring spinning is the largest and most versatile spinning method on the market, and the strip or roving is introduced by the rotation of the ring strand through the ring strand, the bobbin winding speed is faster than the wire ring, and the cotton yarn is twisted It is widely used in all kinds of short fiber spinning engineering.

- Q: When the textile industry, as well as the history of the textile industry development?

- Ancient Chinese textile and printing and dyeing technology has a very long history, as early as in the primitive society, the ancients in order to adapt to climate change, has learned to take the land, the use of natural resources as textile and printing and dyeing raw materials, and the manufacture of simple textile tools. Until today, our daily clothing, certain daily necessities and works of art are the products of textile and printing and dyeing technology.

- Q: What is the current domestic textile enterprises?

- Hengli Group Co., Ltd., Shandong Ruyi Technology Group Co., Ltd., Ningbo Shenzhou Knitting Co., Ltd.

- Q: How is the machine automatically connected to the machine?

- Pick yarn yarn, so that cotton fiber, synthetic fiber and wool fiber and other raw materials of different colors and monochrome warp can be firmly together, so the smooth completion of the process

- Q: Who invented Jenny spinning machine?

- In 1768, Hargreaves won the patent; by 1784, "Jenny machine" has increased to eight spindles. Four years later the United Kingdom has twenty thousand "Jenny machine".

- Q: Why did the first industrial revolution begin with the sign of Jenny's textile machine rather than shuttle?

- In the 1860s, the industrial revolution began with the British cotton industry, and then spread to mining, smelting, transportation and other industries in Europe

- Q: What is the historical background of the mechanization of the British cotton textile industry?

- Technology: Accumulation of workshop handicraft technology;

Send your message to us

Tight Fabric Cone Bobbin Winder Machinery for Textile

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches