Three-dimensional Plastic extruder Blow Molding Machinery

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

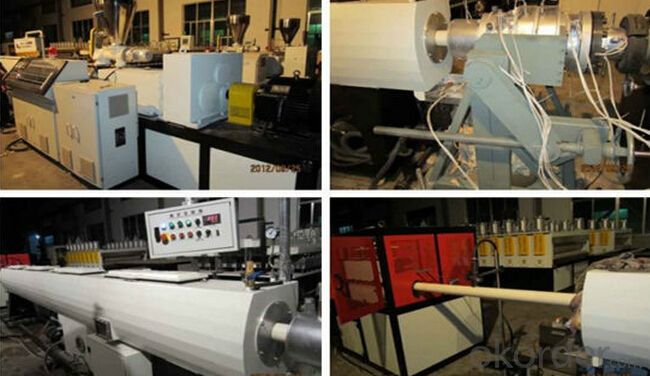

Product introduction

Our machines are usually used to make bottles, jars, pallets, jerry cans, water tank, chairs,tool boxes, suitcase,drums, barrels, plastic balls and so on. For example, our machine can manufacture bottles range from 2.5ml to 3000L.

So further details or questions, just contact us for more information,I am Jenny.

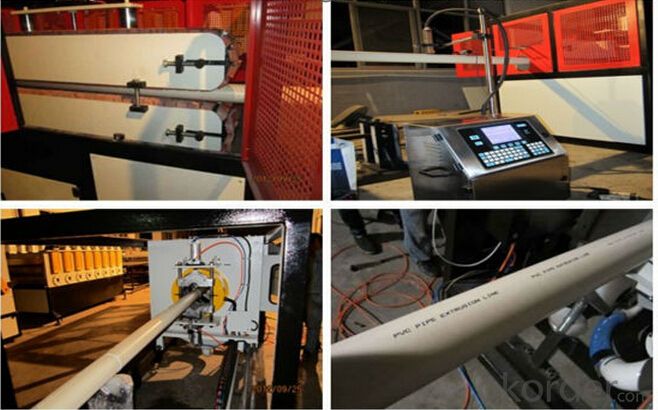

Pls allow me to show some pictures about our machines ,their products,our factory, our certifications and other details about us ----CNBM Machinery.

Features:

1. 100 point axis wall thickness control system

2. two pulling-rod clamping structure-stable and reliable

3. Options: single layers, 2 layers, 3 layers, 6 layers etc.

Drum and tank machines have patents: 3 layers (save significant cost on purchasing raw materials)

Middle layer-recycling material (50-70% adjustable) as following.

4. Specially designed clamping cylinder-energy-saving

5. Hydraulic system by servo-high energy-saving

6. PLC touch screen by OMRON-easy to operate

7. Stock extruder for better consistency in parison weight

8. Induction Heaters-energy-saving (save 50% of electricity)

9. Spiral flow channel design on die head without weld point-homogeneous distribution

10. Quick color changing

Application:

This Blow Molding Machine can produce plastic blow molding products such as pallets, fuel tank of vehicle, chemical container etc. The maximum container volume is 1500L.

Technical parameters:

Product show:

FAQ:

1.Q:Are you a factory or trading company?

A: We are one of the most professional manufacturer of blow molding machine in China

2.Q:Where is your factory located? How can I visit there?

A: Our factory is located in Zhangjiagang City, China. You can fly to Shanghai airport. All our clients, from home or abroad, are warmly welcome to visit us!

3.Q:How can I get your quotation?

A: Please send me several photos of the products (bottle, container,etc) for reference, and tell me the bottle volume(liter), can the capacity (piece/h)??

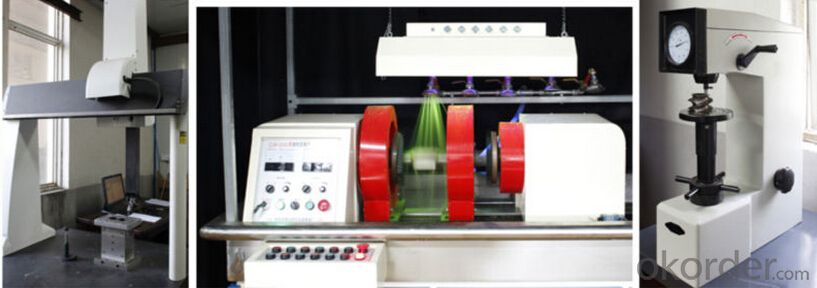

4.Q:How does your factory do regarding quality control?

A:"Quality is priority. we always attach great importance to quality controlling from the very beginning to the very end. Our factory has gained CE, SGS authentication.

- Q: Dr. oil mill, bag filter, instructions for use

- The water vapor entering the condenser is cooled and then returned to the original water. The oil in the vacuum heating tank is drained into the static filter by the oil pump and filtered out by the filter oil paper or filter element. Thus, the whole process of removing impurities, moisture and gas in the oil by the vacuum oil filter is completed, so that the clean oil is discharged from the oil outlet.

- Q: How much is the optimum temperature for cooking oil in a centrifugal oil filter?

- 70-80 degrees is the best filter temperature, and I hope to help you!

- Q: What is the effect of the oil filter on the filtration of fine particles?

- When the temperature occurs, the reactions will not react with the filtered liquid and will pollute the filtered liquid. As long as it is not the core technology of the company, the problem of oil treatment and filtration can be exchanged.

- Q: What cloth is the filter cloth used to filter oil? Where can I buy it?

- On the other hand, the smaller aperture, the more oil filter mesh, the speed will be slow, but the oil filter cleaner.Generally it is necessary to configure the speed of the oil filter and the type of oil filter.

- Q: Which filter is the best for peanut oil filter?

- The peanut oil filter is divided into centrifugal oil filter, plate and frame oil filter and vacuum oil filter

- Q: What is the meaning of cleanliness of oil filter less than or equal to 6?

- Later with the cleanliness of concept in the expansion of different industries, the United States Aircraft Industry Association (ALA), the American Society for testing and materials (ASTM), the American Society of Automotive Engineers (SAE) jointly proposed in 1961 MOOG (SAE - 6D) oil cleanliness standard

- Q: What are the oil filters for? What are they used for?

- The oil filter is generally used for on-line lubrication system of large equipment, that is, when large equipment is in normal operation

- Q: Is the temperature of the Kato vacuum pump casing working high and normal?

- Breaking oil solenoid valve, or coil damage or electromagnetic valve diaphragm rupture or aging, oil breaking solenoid valve generally appear in the old models;Cooling fan motor fault;The exhaust duct is not unblocked or the exhaust resistance (back pressure) is large;The ambient temperature exceeds the specified range (38 degrees C or 46 degrees C).Hope to be of help to you.

- Q: What happens when the oil heater is fired and the heater is tripped?

- Oil filter is mainly used to improve the cleanliness of machinery and electrical oil, so as to give full play to the best performance and extend the service life of equipment.

- Q: What kind of oil can the oil filter handle?

- Only 1, ordinary oil filter cleaning and removal of micro water, such as frame type oil filter, oil filter machine, portable portable oil filter, can handle the oil is usually low viscosity lubricating oil, hydraulic oil, this kind of equipment can also be used as fuel for oil.

Send your message to us

Three-dimensional Plastic extruder Blow Molding Machinery

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords