Plastic Sheets - Thermoforming Good Self-Lubricating UHMWPE Sheet

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 kg

- Supply Capability:

- 15000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Thermoforming Good Self-lubricating UHMWPE Sheet

Description

UHMWPE(Ultrahigh molecular weight polyethylene) is widely used as engineering material. In the same condition, UHMWPE is harder than iron. It has also good self-lubricating, lighter and more durable, so some manufacturer has choose it to replace iron.

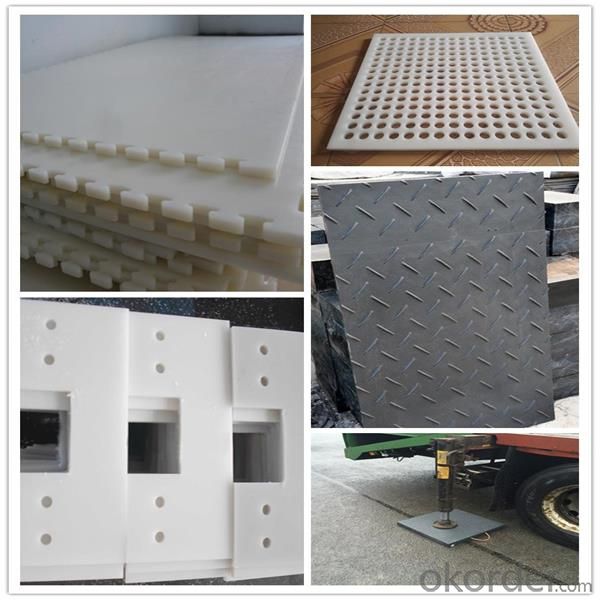

Appication

Synthetic Ice Rink Board

Profiled Part

Equipment Liner

Conveyor Roller

Drag Flights

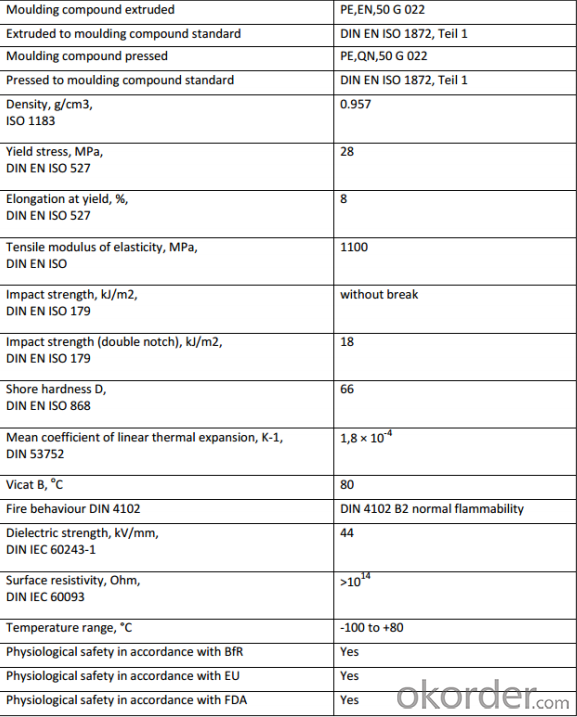

Property

Our Service

OEM is accepted.

Free Sample is OK.

Company Information

Packaging and Shipping

FAQ

1. When can I get the price?

We usually quote within 6 hours after we get your inquiry.

If you are very urgent to get the price, please call us or tell us in your email so that we will regard your inquiry priority.

2.How can I get a sample to check your quality?

After price confirmation, you require samples to check our quality. If you just need a blank sample to check the design and quality, we will provide you sample for free, as long as you afford the express freight.

3.How long can I expect to get the sample?

After you pay the sample charge and send us confirmed files, the samples will be ready for delivery in 3-5 working days.

The samples will be sent to you via express and arrive in 3-5 days.

You can use your own express account or prepay us if you do not have an account.

4.What about the lead time for mass production?

Honestly, it depends on the order quantity and the season you place the order.

Generally speaking, production lead time is within 2~4 weeks.

5.What is your terms of delivery?

We accept FOB, CIF, etc. You can choose the one which is the most convenient or cost effective for you.

6.Terms of payment?

Our usual payment is T/T, L/C. You can choose the best one according to your situation:

30% T/T deposit, 70% balance before delivery.

100% T/T in advance.

Waiting your reply!

- Q: Are plastic sheets resistant to warping due to temperature fluctuations?

- Yes, plastic sheets are generally resistant to warping due to temperature fluctuations. However, the specific type and quality of plastic used can affect their resistance.

- Q: Can plastic sheets be used for vacuum forming in the aerospace industry?

- Yes, plastic sheets can be used for vacuum forming in the aerospace industry. Vacuum forming is a widely used manufacturing process in aerospace for creating lightweight and complex shapes. Plastic sheets, such as thermoplastics, are heated and then molded over a pattern or mold using vacuum pressure. These formed plastic parts can be used for various applications in the aerospace industry, including interior components, aircraft panels, and even some structural parts.

- Q: Are plastic sheets resistant to degradation from cleaning agents?

- Yes, plastic sheets are generally resistant to degradation from cleaning agents.

- Q: What are we up to?

- I'm sorry. I got to the 'chocolate' part and forgot everything else. What were we talking about again?

- Q: Are plastic sheets impact resistant?

- Yes, plastic sheets can be impact resistant depending on the type of plastic used and its thickness. Some plastics, such as polycarbonate and acrylic, are known for their high impact resistance, making them suitable for applications where protection against impacts or breakage is required.

- Q: Can plastic sheets be bent or molded into shapes?

- Yes, plastic sheets can be bent or molded into shapes through various methods such as heating, vacuum forming, or using molds and presses.

- Q: Long time use of plastic boards will cause harm to the body

- You feel the plastic board if there is a problem as far as possible for it, although the cut vegetables also in a moment, most will not have what effect on the dish, but for a long time there will be a knife grinding plastic chopping board some plastic debris down, mixed with cooked food is not good.

- Q: Can plastic sheets be used for electrical insulation?

- Yes, plastic sheets can be used for electrical insulation.

- Q: What's the plastic board that sits on the window of the car?!

- Generally referred to as "rain strip", in rainy days, both want to shake down a little door glass, breathable, and at the same time to prevent the rain from the seam oblique drift in.

- Q: Which flexible transparent plastic sheet is resistant to dichloromethane or Tetrahydrofuran?

- Such a thing exists!? If it does, they should make disposable gloves out of that! I could use some in my lab...

Send your message to us

Plastic Sheets - Thermoforming Good Self-Lubricating UHMWPE Sheet

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 kg

- Supply Capability:

- 15000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords