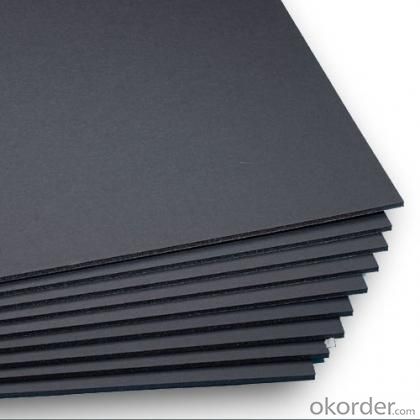

Plastic Sheets - Heat Insulation High Density PVC Foam Board

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Product Specifications:

Specifications: 1220*2440mm, 1560*3050mm, 2050*3050mm

Thickness: 1-33mm

Density:0.43-0.9g/cm3

Color: Mainly white, Black

2 .Product usage:

1mm-5mm Suitable for advertising materials, electronic instruments, packaging

15mm-20mm Suitable for furniture

10mm-20mm Suitable for bath cabinets

5mm-20mm Exhibition board, indoor and outdoor decorative panels (different customers have different requirements)

3mm Film Suitable for car interior ceiling

PVC foam board part of the end product icon:

3 .product features and advantages

A. The characteristics of waterproof, flame retardant, acid and alkali, mothproof, lightweight, heat insulation, sound insulation and damping.

B. and the same processing of wood, and processing performance is far superior to wood

C. is an ideal substitute for wood, aluminum and composite plates.

D. skin plate surface is very smooth, high hardness, not easy to have scratches, commonly used in the production of cabinets, furniture, etc.

4 .PVC foam board market prospect:

PVC foam has many advantages, the application of a very wide range, at present in developed countries has been a very wide range of applications, and the development of more slowly in china. With the country's energy saving and environmental protection requirements of building materials and other materials and the increasing scarcity of wood resources in China, PVC foam board will usher in rapid development.

5. Product Features

(1) Light weight, waterproof, fire retardant and self-extinguishing

(2) Sound insulation, heat insulation, noise absorption, heat preservation and anti-corrosion.

(3) Tough, rigid with a high impact strength, not easy to age and can keep its color for long

(4) Easy to clean and maintain.

(5) Environmental- friendly green and lead-free.

6. FAQ:

(1)What is PVC board?

the implementation of GB/T4454-1996 quality, good chemical stability, corrosion resistance, high hardness, high strength, high strength, anti UV (aging), fireproof (self extinguishing), reliable insulation performance, smooth surface, no water, no deformation, easy processing etc.. This product is excellent heat molding material, can replace part of the corrosion resistance of stainless steel and other synthetic materials, and is widely used in petroleum, chemical industry, electroplating, water purification equipment, environmental protection equipment, and mining, medicine, electronics, communications and decoration industries.

(2)Main product specifications

Size: 1220*2440mm (about 70% of sales),

1560*3050mm (about 20% of sales),

2050*3050mm (about 10% of sales)

Main product thickness:1mm,2mm,3mm,5mm,8mm,10mm,12mm,15mm

Product details photo:

- Q: What are the common applications of plastic sheets?

- Plastic sheets have a wide range of common applications, including packaging materials, construction materials, automotive components, signage, electrical insulation, greenhouse coverings, and various DIY projects.

- Q: Can plastic sheets be used for insulation against electromagnetic interference?

- Yes, plastic sheets can be used for insulation against electromagnetic interference.

- Q: i want to make prints on sheets like the kind used on MTG life counters. i have a website on the bottom to show what im talking about. where do i get this plastic sheets from and how do i print on them?

- This isnt something that you can put through your regular printer. Your home printer rolls the paper over a relatively tight turn while its printing. The plastic your looking at is too stiff. Most of this stuff was screenprinted. Find a local screenprinter if your still interested and they can hook you up.

- Q: after buying the motor home i found out that water from the water source in the rv park had been standing under the trailer for a long time. i was planning to move the home so thought this would be resolved but now do not know that i should move or keep this due to what looks like mold on the surface of the black plastic sheeting containing the insulation under the trailer. also, it s there a problem if water gets into the insulation? this is my first experience with a mobile home do not know who to ask. mobile home dealers have not been able to answer my question. please help.

- I can't see why mold on the exterior of the plastic sheeting should be a problem unless there's an enormous amount of it, if it's there because the underneath of the home didn't get enough ventilation. It could be cleaned off, and shouldn't recur if the next place you put it is dry. If water has gotten into the insulation above the plastic, that would worry me. Wet insulation doesn't work, and if the insulation is wet, there might be other water damage in other parts of the home which could be serious, since the water in the insulation most likely flowed down from somewhere. Is the plastic in good shape with minimal tears in it? If there are any tears, look at the insulation through them to see if you can see any evidence of it having been wet. Have a good look with a strong light under there, and you might be able to answer your own question. Also, though the dealers might not be of much help, there is probably someone in the neighbourhood who does repairs on mobiles, and it might be worth getting them to give an opinion.

- Q: Do plastic sheets have any impact on insulation efficiency?

- Yes, plastic sheets can have a positive impact on insulation efficiency. When properly installed, plastic sheets can act as a vapor barrier, preventing moisture from seeping into insulation materials and reducing their effectiveness. Additionally, plastic sheets can help to seal air leaks, improving the overall insulation performance of a structure.

- Q: I have been looking online.. So if anyone has bought it before from a store, please let me know, I only 1 large sheet not a bulk.Thanks!!

- Home Depot, Lowe's or Ace.

- Q: I was wondering if there was any type of Vinyl or Plastic sheeting that you can adhere together by Melting it? to make a box or something?

- For diy you can use chloroform, it is used to stick plastic together by dissolving the contacted areas. Most sign makers and art/craft makers are using it. Hot mouldings are usually used by the manufacturing industry.

- Q: If not, what kind of screws should I use?

- Yes, and coarse thread wood screws work too.

- Q: A proton (m= 1.67x10^-27kg) moving at 4.0x10^7m/s shoots through a sheet of foam plastic .25 cm thick and emerges with a speed of 1.5x10^7 m/s A) How long does it take to pass through the plastic?B) What average force retards the proton's motion through the plastic?Hints: Fext T+MVi=MVf Ans: A. 9.09x10^-11s B.4.59x10^-10N

- A) d = Vavg * t 0.0025 m = ?(4.0 + 1.5)e7m/s * t t = 9.09e-11 s B) The hint uses the impulse equation: impulse + initial p = final p F * 9.09e-11s + 1.67e-27kg * 4.0e7m/s = 1.67e-27kg * 1.5e7m/s F = -4.59e-10 N Since the force is against the direction of motion, I think it should have a negative sign; your answer suggests it isn't warranted. Without the hint, you could do acceleration a = Δv / Δt = (1.5 - 4)e7 m/s / 9.09e-11s = -2.75e17 m/s? and then F = m*a = 1.67e-27kg * -2.75e17m/s? = -4.59e-10 N If you find this helpful, please award Best Answer!

- Q: I can't think of the name of this material at the moment and have searched the net to no avail so far. They are made to look like tiles/slates but come in sheets measuring about 8x4 ft. They are light by comparison with the real thing and would suit the roof I need to cover. Can anyone refer me to a website dealing with them or give me any details as to how they are installed? Thanks for the info!!!

- 4' x 8' plywood is often used to 'sheath' a roof. Corrugated metal or fiberglass/plastic has been used to cover roofs and they can come in 4 x 8 sheets I don't believe the fiberglass/plastic, or that formica, (which is what I think you mean by 'plastic tiles/slates) will satisfy most fire codes.

Send your message to us

Plastic Sheets - Heat Insulation High Density PVC Foam Board

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords