The Storage Bottle Of Edible Oil JPB

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

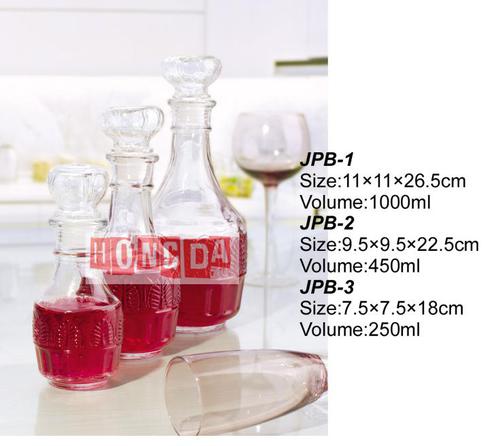

This product bottle with maple leaf pattern design, beautiful and elegant, can contain all kinds of edible oil, wine, fruit juice, beverage, bottle cap for bottle design, special rubber sealing ring with food, health and safety.

(Filler belonging to display products, not in the sales range)

JPB-1 Size:11x11x26.5cm Volume:1000ml

JPB-2 Size:9.5x9.5x22.5cm Volume:450ml

JPB-3 Size:7.5x7.5x18cm Volume:250ml

- Q: Glass raw materials processing equipment, glass raw materials crushing equipment prices generally sell how much?

- The above two processes generally has the following disadvantages: 1, unit 2, a large scale of investment products; metal consumption per unit of product 3, amazing; by-products (<0.1mm) high proportion; 4, wet production requires a large amount of water and cold in winter can not produce.

- Q: What is glass made of?

- Melting, the raw materials will be prepared by high temperature heating, forming a homogeneous bubble free liquid glass. This is a complex process of physics and chemistry. The melting of glass is carried out in a furnace. There are two main types of Furnaces: one is a crucible kiln, the other is glass in the crucible, and the other is heated outside the crucible. The small crucible kiln has only one crucible, and the larger one can be more than 20 crucibles. The crucible kiln is made by gap type, and now only optical glass and color glass are produced by crucible kiln. The other is the tank furnace. The frit is molten in the bath, and the flame is heated on the upper part of the glass. The glass melting temperature mostly in the 1300~1600 C Eve joy. Most of them are heated by flame and a few are heated by electric current. They are called electric furnaces. Now, the pool kiln is continuous production, small pool kiln can be a few meters, big can be more than 400 meters

- Q: Glass factory raw materials specific to do?

- Glass is formed by melting sand with other chemicals (the main ingredients are: soda ash, limestone, quartz). A continuous network structure is formed during melting, and the silicate like non-metallic material is gradually increased and hardened in the process of cooling. The chemical composition of ordinary glass is Na2O, CaO, 6SiO2, the main component is silica, is a kind of amorphous structure with irregular structure. Widely used in buildings for wind and light transmission; of mixtures. There is also colored glass mixed with certain metal oxides or salts, and toughened glass made by special methods. Sometimes some transparent plastic (such as polymethyl methacrylate) is also called organic glass.

- Q: What is the difference between white float glass and ordinary float glass?

- Ultra white is generally used in solar panels, raw materials, aluminum content higher

- Q: Yacht enterprises are purchasing their own raw materials (resin, glass fiber, carbon fiber, etc.), home composite products, accessories?

- General purchases of raw materials are their own, the general yacht above the bottom of the ship is a manufacturer, the ship is also a cloth manufacturers, as well as small boats on the yacht is also a manufacturer

- Q: The shell of glass steel electric cars will not be on the poor out of the glass Sizha?

- There are 2 kinds of process for making automobile shell with glass fiber reinforced plastic, 1. hand paste forming process and 2. pressing processThe choice of raw materials is reasonable, according to the operating procedures, the product is not defective, will not appear exposed fiber, it will not cause skin itchingA small number of unscrupulous manufacturers, technical level is low, Jerry built products must be betterYou can spray a layer of resin or a layer of dry adhesive tape on the exposed surface of the fiber when you encounter inferior products

- Q: What are the characteristics of the gas flow in the flame space of a glass furnace?

- Ordinary glass plate glass, wire glass and quartz glass (also known as crystal glass) a molding. Wired glass as the quartz glass; only a raw material of sandstone or silica or quartz sand. Tempered glass is made of flat glass as raw material for re processing: the cut of the flat glass into the tempering furnace, heating to about 650 degrees, with cold air quenching, glass forming hardening - tempering. Accomplish!

- Q: What happens when toughened glass breaks?

- A ton of glass raw materials, at least 3-4 of nickel sulfide crystals, the number of tons of glass made of pieces of a square size glass, which will have 3-4 to explode, which is self depicting the image of.

- Q: How do you pack something into (Qian Jin) plexiglass?

- I have been in touch with gel products for a while, and I feel that if the discharge circuit is too soft, it will be easy to damage the circuit board. As far as plexiglass is concerned, I have to ask my fellow inorganic students how they did it.

- Q: What kind of film is toughened glass film?

- PP materialPP protective film material is first appeared in the market, the chemical name is polypropylene, no adsorption capacity, generally use glue to stick, tear after the glue will leave marks on the screen, the screen for a long time will be corrosion. This material has been basically eliminated by the vast number of protective membrane manufacturers, but some roadside stalls are still selling, we should pay attention to!

Send your message to us

The Storage Bottle Of Edible Oil JPB

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords