The Middle Cold Resistant, The Glass Transition Temperature Of Minus 72 Degrees

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description of Rubber:

Natural rubber is a kind of polyisoprene as the main component of natural high molecular compound, its composition in 91% ~ 94% is the rubber hydrocarbon(polyisoprene), the protein, fatty acid, carbohydrate, ash and other non rubber substance. Natural rubber is the most widely used general rubber..

2. Main features of Oil Seal:

1) High Elasticity, According To The Formula, The Elastic Can Reach 80% Of The Maximum.

2) High Elongation, The Maximum Can Reach More Than 1000%.

3) The Elastic Modulus And The Shear Modulus Is Low, Than Some Rigid Substances Such As Iron And Steel And Other Low Much.

4) Cold Resistant, The Glass Transition Temperature Of Minus 72 Degrees

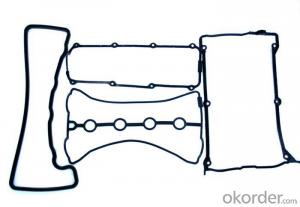

3. Rubber Images:

4. Rubber Application:

Rubber elasticity, good insulation, impermeability and plasticity characteristics of natural rubber, and through the mix after appropriate treatment also has oil resistance, acid and alkali resistance, heat resistance, cold resistance, pressure resistance, wear resistance and other properties, therefore, has the widespread use, mainly used for automobile, machinery, industrial etc. industry as a shock, sealing parts.

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Rubber is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: How do i change out my cv axles on my 1992 mitsubishi 3000 gt?

- Before you even start, loosen the big axle nut you see when you remove the wheel cover. If you can't do that, don't start the job. You need a big breaker bar and socket to loosen the axle nut, and you want the car sitting on its tires when you loosen it. If you don't have jack stands, you can't do the job. A floor jack makes things a lot easier. You'll need an alignment when you finish. Do you want to change your McPherson strut shocks and upper isolator bushings at the same time? If so, you may need a spring compressor tool. Are you really up for this job?

- Q: Does the 2009 SR Suntour Rux have 20mm Thru Axle? Also for this fork 2008 Sr Suntour SF7 XCM?

- I would recommend upgrading from SR Suntour forks, they are a pretty poor fork. If your budget it ?300 then potentially you could pick up some Fox forks, which are generally accepted as the best fork around however you'd be getting them second hand. But they are a VERY good fork. Alternatively, look at DT SWISS forks or Rock Shox, the latter being the cheaper forks of the two. When buying a fork you need to make sure the travel of the fork isn't too much for your bike, you can find this out on the scott website most likely. The reason for this is that frames are made for a certain size fork (in your case most likely 100mm), by sizing up to a fork with larger travel you change the geometry of the bike frame thus changing the angles and distribution of force onto your downtube, which can result in a breakage. You should be able to get away with something like a 20mm increase in fork travel any higher could be dangerous, but of course you need to check what your frame can handle, try looking in the manual. You also need to measure the steerer length, which is the piece of the fork that goes through your frame, make sure that the forks you purchase steerer is long enough to go through your steerer tube and accomodate a stem and headset. You need to measure your current steerer and width of your components to check this.

- Q: I got my axle fix a year ago, and now I have to get it fix again. It one or the other. We get one fix then the other needs to be fix a few month later. Are we getting made by the auto place. I need to know how long it should last to. So please just don't say yes or no. I need a true answer. Please help.

- Ignore that guy, just because he's a tech means nothing. I've been low nearly scrubbing the ground with a 38mm spacer on my Daily Driver. A car that is 20 years old, and your car isnt nearly that old. I slide my car daily and beat on it and I havent had a single problem caused by the spacers. You'll be fine. Just be careful not to curb your new rims! :) Good Luck

- Q: I was backing up and scratched the side of my car against a tree. It was the left (drivers side) rear that was scraped above the wheel well (if that‘s what the big part above the tire is called. I didn‘t think it was that bad, but I thought my car was driving weirdly so I got out to look and there was a huge, deep gouge in the side of the car above the tire. I was able to drive the car home but i felt like it was weird the whole time.I also thought there were noises coming from the back when accelerating, even in a straight line. I know the car needs cosmetic repairs (the metal is torn up along one, long scratch and very badly scratched on other parts). What did I do to my car?I was seeing if online forums could help, and seem to have freaked myself out thinking I had somehow damaged the axle/shaft in the process. If anyone could help that would be fantastic?I just want to know what kind of repairs I‘m looking at and approximately how much they will cost.

- check to make sure the body isn't pushed up against the tire or anything in the wheel well. Otherwise you may have a bad wheel bearing or axle shaft bearing. Also, may be a bad universal joint in the rear drive shaft. Check it out,

- Q: Might I need an alignment after replacing the clutch and both axles?

- GET THE AXEL FASTER NO MESS AND THEY ARE CHEAP. I WORKED FOR L.V HONDA FOR 10 YRS AND HONDA STILL CANT MAKE A GOOD AXEL LOL BUY THE WHOLE THING DONT UNDO THE WISH BONE THE AXEL WILL SLIDE THROUGH STRUT WISHBONE.

- Q: I am currently using a Fred Bear Game Over and I have tried a release and finger shooting.I much prefer to use my fingers, but I am a little worried about the extreme angle of the bow string when I draw back.I use 2 fingers under my arrow when i draw and because of the high angle the string is on at full draw because of the short axle length, it looks although my arrows might be slightly un-nocking.Should I be using a different technique (eg. one finger above and one underneath the arrow) or is the way I‘m doing it fine?I‘m asking because I dont want to cause damage to my bow from my arrows not nocking properly on the string.

- Here is the problem you are having. Today's short axle compounds are not designed for fingers.And the sooner you find that out and go to a release the better off you will be. I grew up shooting fingers. I dearly love the feel of a bow drawing it back with my fingers.But after a lifetime of finger shooting 3 years ago I finally gave up and went to the hated release. It had become impossible to get good broad head flight under hunting conditions when I was drawing the bow back with my fingers. It was hard to make the changeover because I had shot fingers so long. But as soon as I got accustomed to it, my groups tightened up tremendously and my problems with broad head flight was over with. My last 12 bow shots were one shot kills and hit the same spot I was aiming at on each deer. It took me many bad hits and a few total misses to finally convince me to go to the release and give up on the finger shooting.Now it is time for you to make your decision. You at some point are going to have to go to a release. I suggest you do it now before your frustrations and dry fires get the best of you and your bow.Believe me, I know how you feel about shooting fingers. But until a bow hits the market again at 42 plus inches axel to axel, finger shooting is a thing of the past.

- Q: Hi,Please excuse my ignorance but can you tell from these specs what the length of axle to crown is for 26 wheel ? Being a newbie I don‘t understand how to decipher the numbers yet.Thanks!Travel 50 (40) (30) mmSystem External coil springLower SteelDesign Leading axleDynamo bracket mounting boss Yes / Option (Brazed on)Leg Color Gloss black, Metallic silverCrown AlloyIntegrated HD Semi ID type / 43mmStanchion tube STKM / with DustbootsRight Side External coil springLeft Side External coil springSteerer tube STKMLenght ( w / o thread ) 255 mmLenght ( w / 55mm thread ) 150, 180, 210 mmCrown race diameter 30, 27 mmWheel size 700C, 26, 24, 20Brake V-type (Disc: option)Preload adjuster N/ADynamo bracket shape N/ANote Brazed on d.bracket mount or HB dynamo cable guide

- I don't see anything that is close to the crown to axle measurement.

- Q: I am an archer and a beginning hunter and im wanting to purchase a compound bow. But there are so many factors in finding out which bow is right for me! So, i want to understand what some of the factors are.One of them i hear alot of people talking about is the axle to axle. What is this? Also, how do you aim with a compound bow? Im used to a bow with no pins or peep sights.

- Axles are not the pulleys. That's like saying the wheels on your car connect inside the differential. The axles are the, well axles, that the pulleys sit on. Axle to axle is the measurement between them.

- Q: replaced right side CV axle, car still does not move but speedo shows 85 when in drive?

- some cars transaxles are built so that you have to remove the axles in a certain order.as well as put them back in a certain way.most likely when you pried the old axle out the gear inside dropped and the spline on the end of the axle are in nothingalso make sure the axle is seated all the wayand make sure inner spline shaft is the exact same length as what came out of it!!!! if this isn't what is wrong then I would say you have internal transaxle issues which are going to require a pro!!! good luck.I hope it is nothing more than not seated all the way!!!!

- Q: axle housing

- crush the ore and add lots of heat.

Send your message to us

The Middle Cold Resistant, The Glass Transition Temperature Of Minus 72 Degrees

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot Searches