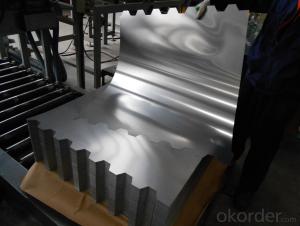

TFS/Tin Free Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications&Information:

Annual capacity: | 12 0000 MT/ year |

Operate standard: | JIS G 3315、GB24180 |

Base plate: | SPCC/MR |

Thickness : | 0.15mm~0.36mm |

Width: | 520mm~950mm |

Length: | 1018mm;828mm;coil;or per your requirement |

Coating | 80~100mg/㎡ |

Temper : | T2,T2.5,T3,T3.5,T4,T5,DR-8,DR-9 |

Finish : | bright / matte/stone |

Packing: | plastic film, anti-rust paper,galvanized iron cover |

Loading : | 20f container with Max weight 25 Ton |

Shipping time: | 30~60 days after the receipt of buyer’s deposit |

Payment : | L/C or 30% TT in advance,70% against copy B/L |

MOQ: | 50 MT |

- Q: How does tinplate contribute to the overall protection of packaged products?

- Tinplate contributes to the overall protection of packaged products by providing a durable and corrosion-resistant barrier. This helps to prevent contamination, spoilage, and damage from external factors such as moisture, oxygen, light, and microorganisms. Tinplate also offers excellent heat resistance, ensuring the integrity and safety of the packaged products during transportation, storage, and usage.

- Q: What are the typical dimensions of tinplate sheets?

- The typical dimensions of tinplate sheets can vary, but they are commonly available in sizes ranging from 0.15mm to 0.35mm in thickness, with widths of 600mm to 1200mm, and lengths ranging from 800mm to 2400mm.

- Q: What are the main regulations governing tinplate production?

- The main regulations governing tinplate production vary by country and region. However, some key regulations typically include guidelines on the use of materials, such as the type and thickness of tin coatings, as well as regulations on production processes to ensure safety and quality standards are met. These regulations may also cover areas such as labeling, packaging, and transportation requirements to ensure proper handling and traceability of tinplate products.

- Q: How is tinplate coated with protective lacquer?

- Tinplate is coated with a protective lacquer through a process called electrostatic spraying. The tinplate is first cleaned and degreased to ensure proper adhesion of the lacquer. Then, the lacquer is applied to the tinplate using an electrostatic spray gun, which charges the lacquer particles and attracts them to the metal surface. This creates a uniform and durable coating that provides protection against corrosion and enhances the tinplate's overall appearance.

- Q: What are the typical lead times for tinplate tooling?

- The typical lead times for tinplate tooling can vary depending on the complexity of the design and the specific manufacturing processes involved. However, on average, lead times can range from several weeks to a few months.

- Q: What are the different coating weights available for tinplate?

- The different coating weights available for tinplate typically range from 1.1 to 11.2 grams per square meter (g/m²).

- Q: Can tinplate be used for medical or pharmaceutical packaging?

- Yes, tinplate can be used for medical or pharmaceutical packaging. Tinplate is a strong, durable, and corrosion-resistant material that provides an effective barrier against moisture, light, and oxygen. It is commonly used for packaging pharmaceutical products, such as tablets, capsules, and ointments, as it helps to maintain their quality, integrity, and shelf life. Additionally, tinplate is also widely used for medical packaging, including sterilized instruments, bandages, and other medical devices, due to its hygienic properties and ability to protect the contents from external contaminants.

- Q: What is tinplate?

- Tinplate refers to thin sheets of steel that have been coated with a layer of tin. It is primarily used in the packaging industry for manufacturing cans and containers due to its corrosion resistance and ability to preserve the quality of food and beverages.

- Q: How is tinplate tested for quality control?

- Tinplate is tested for quality control through various methods including visual inspection, measurement of coating thickness, adhesion testing, and corrosion resistance testing.

- Q: How is tinplate printed and decorated?

- Tinplate is commonly printed and decorated using various methods such as lithography, offset printing, and digital printing. These techniques involve applying ink onto the tinplate surface using specialized machines and equipment. The design or artwork is transferred onto the tinplate through a series of steps, including image preparation, plate-making, and printing. This process allows for vibrant and detailed designs to be applied to the tinplate, enhancing its visual appeal and marketability.

Send your message to us

TFS/Tin Free Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords