Quality of Tin Free Steels TFS

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

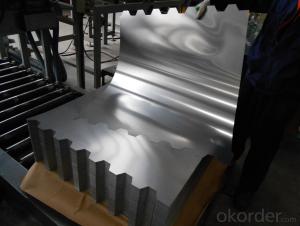

Tin Free Steel (TFS)

Is also known as chromed steel, as it is obtained by coating the metal base (low-carbon steel) with an ultra-thin layer of metallic chrome and then with a chromium oxide layer.This steel product was developed to meet economic requirements, and excels tinplate in paintability, paint adhesion, and economy. It is widely used for making beverage cans and 18-liter cans. It is also used for making photographic film cases and as a protective material for optical fiber cables.

Our TFS Specification:

Standard: AISI, ASTM, BS, DIN, GB, JIS

Material: MR,SPCC

Thickness:0.15mm - 0.45mm

Width: 600mm -1150mm

Temper: T1-T5

Annealing: BA & CA

Coil Inner Diameter: 508mm

Weight: 6-10 tons/coil 1~1.7 tons/sheets bundle

Oil: DOS

Surface: Finish,bright,stone,matte,silver

Packing:

1、For sheets: plastic or waterproof paper, metallic cover and angles, steel strips,wooden pallet.

2、For Coils: plastic or waterproof paper,plastic protect plate,steel strips.

Both Prime and Second Quality Are Available!!!

- Q: How long does tinplate last?

- Tinplate can last for several decades if properly maintained and protected from corrosion.

- Q: What are the main applications of tinplate in the cosmetics industry?

- Tinplate is widely used in the cosmetics industry for packaging various products such as lip balms, creams, powders, and even aerosol cans. Its corrosion resistance, durability, and ability to maintain product integrity make it an ideal choice for ensuring the quality and longevity of cosmetic products. Additionally, tinplate's versatility allows for attractive and customizable designs, enhancing the visual appeal of cosmetic packaging.

- Q: How does tinplate perform in high-temperature applications?

- Tinplate performs well in high-temperature applications due to its excellent heat resistance and durability. It can withstand elevated temperatures without warping, melting, or releasing harmful substances, making it a reliable choice for various industrial and packaging uses.

- Q: How is tinplate coated for cosmetic packaging?

- Tinplate is typically coated for cosmetic packaging through a process called electrolytic tin coating. In this method, a thin layer of tin is electroplated onto the surface of the tinplate to enhance its corrosion resistance and provide a smooth and attractive finish.

- Q: How to quickly open the bottle?

- A tin can be opened, the handle is separated, and the canned fruit can be clamped by the head, and the rotating knob and the tin can be opened. Remember, when you turn the knob, you can only rotate clockwise and turn counterclockwise clockwise.

- Q: How does tinplate contribute to the preservation of historical artifacts?

- Tinplate contributes to the preservation of historical artifacts by providing a protective coating that helps prevent corrosion and deterioration. The thin layer of tin on the surface of tinplate acts as a barrier, shielding the artifacts from exposure to air, moisture, and other harmful elements that can accelerate the degradation process. This preservation technique helps extend the lifespan of historical artifacts, ensuring they can be enjoyed and studied by future generations.

- Q: What is the purpose of tinplate coating?

- The purpose of tinplate coating is to provide a protective layer of tin on steel or iron surfaces, which helps prevent corrosion and enhance the appearance of the metal.

- Q: How does tinplate contribute to the efficiency of energy systems?

- Tinplate contributes to the efficiency of energy systems by providing a highly durable and corrosion-resistant material for the production of energy-efficient appliances, such as refrigerators and air conditioners. Its excellent thermal conductivity properties also aid in the efficient transfer of heat, reducing energy waste. Additionally, tinplate is widely used in the packaging of food and beverages, helping to preserve products and extend their shelf life, thus reducing food waste and energy consumption associated with production and transportation.

- Q: What are the common printing and decoration techniques for tinplate?

- Some common printing and decoration techniques for tinplate include lithography, offset printing, embossing, and metalizing. Lithography involves transferring an image onto the tinplate using a printing plate. Offset printing is a similar technique that uses a rubber blanket to transfer the image. Embossing creates raised or recessed patterns on the tinplate, adding texture and depth. Metalizing involves coating the tinplate with a thin layer of metal, such as aluminum or gold, to create a reflective surface. These techniques are commonly used to enhance the visual appeal and branding of tinplate products.

- Q: How does tinplate contribute to the circular economy in the steel industry?

- Tinplate contributes to the circular economy in the steel industry by being a highly recyclable material. It can be easily recovered and reused, reducing the need for extracting new resources. Additionally, tinplate's durability and corrosion resistance properties make it suitable for multiple uses, further extending its lifecycle and minimizing waste.

Send your message to us

Quality of Tin Free Steels TFS

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords