TFS-TIN FREE STEEL SHEET

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

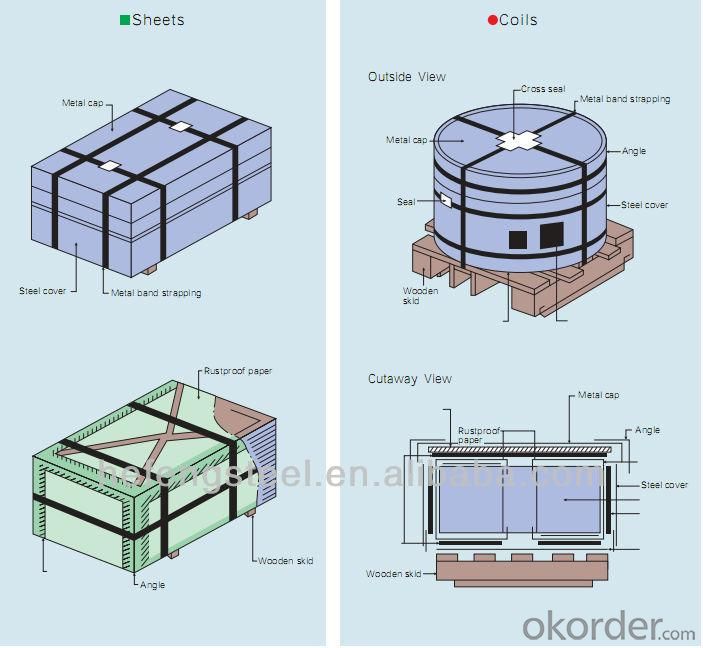

Package details:

Rust-proof paper+thin plastic film+cardboard+galvanized iron+mental band+wooden pallet. Laded into 20 feet container with max weight 25 tons

- Q: How does tinplate handle exposure to pressure and impact?

- Tinplate is known for its excellent strength and durability, making it capable of handling exposure to both pressure and impact effectively. It can withstand moderate levels of pressure without deformation or damage, and its rigid structure helps to absorb and distribute impact forces, minimizing the risk of denting or cracking. Overall, tinplate's resilience and robustness make it a reliable choice for applications where exposure to pressure and impact is expected.

- Q: What are the different methods of recycling tinplate packaging?

- The different methods of recycling tinplate packaging include sorting, cleaning, shredding, melting, and reprocessing. Sorting involves separating tinplate packaging from other materials. Cleaning removes any contaminants from the tinplate. Shredding breaks down the tinplate into smaller pieces. Melting helps to separate the tin coating from the steel base. Finally, reprocessing involves transforming the separated tin and steel into new products or materials.

- Q: What are the main challenges in tinplate transportation?

- The main challenges in tinplate transportation include ensuring proper packaging and securing of the tinplates to prevent damage during transit, managing the weight and volume limitations imposed by transportation regulations, coordinating logistics and transportation routes to minimize delivery times and costs, and addressing potential issues related to customs and import/export regulations for international shipments. Additionally, maintaining product quality and preventing contamination or corrosion during transportation are also important challenges to overcome.

- Q: How does tinplate contribute to the aesthetics of furniture?

- Tinplate contributes to the aesthetics of furniture by adding a unique and visually appealing element. Its shiny and reflective surface can enhance the overall look of furniture, giving it a modern and stylish appearance. Additionally, tinplate can be easily customized and decorated with various patterns and colors, allowing for endless design possibilities and the creation of eye-catching furniture pieces.

- Q: How does tinplate contribute to the performance of sports equipment?

- Tinplate contributes to the performance of sports equipment by providing a durable and lightweight material that is resistant to corrosion. It is commonly used in the manufacturing of cans, containers, and protective coatings for sports equipment, ensuring longevity and enhancing performance. Additionally, tinplate offers excellent adhesion properties, allowing for better grip and control, especially in activities that involve handling equipment such as racquets, bats, or golf clubs.

- Q: How does the thickness of tinplate affect its strength?

- The thickness of tinplate directly affects its strength. Generally, thicker tinplate tends to be stronger and more resistant to deformation or damage compared to thinner tinplate. This is because the increased thickness provides a greater amount of material, resulting in improved structural integrity and resistance to external forces.

- Q: How is tinplate coated for aerosol cans?

- Tinplate is coated for aerosol cans through a process called electrolytic tin coating. In this process, a thin layer of tin is deposited onto the surface of the tinplate by immersing it in a bath of tin solution. The tin coating provides a protective barrier against corrosion and ensures the cans remain durable and airtight.

- Q: How does tinplate perform in terms of insulation properties?

- Tinplate does not perform well in terms of insulation properties as it is a good conductor of heat and electricity.

- Q: How does tinplate perform in terms of moisture barrier properties?

- Tinplate performs exceptionally well in terms of moisture barrier properties. Due to its inherent corrosion resistance and impermeable nature, it effectively prevents moisture from penetrating the surface, ensuring the protection and preservation of the contents within.

- Q: How does tinplate compare to plastic in terms of sustainability?

- Tinplate generally has a higher sustainability profile compared to plastic due to several reasons. Firstly, tinplate is a highly recyclable material, with a recycling rate of around 90%, while plastic recycling rates vary and are generally lower. This means that tinplate is more likely to be reused and diverted from landfills, reducing its environmental impact. Additionally, tinplate production requires significantly less energy and emits fewer greenhouse gases compared to plastic manufacturing. Moreover, tinplate is more durable and has a longer lifespan, making it suitable for multiple uses, whereas plastic is often single-use and contributes to the growing waste problem. Overall, tinplate offers better sustainability prospects in terms of recycling, energy consumption, and durability compared to plastic.

Send your message to us

TFS-TIN FREE STEEL SHEET

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords