Electrolytic Tinplate Sheets for Food Tin Packing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 7000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Electrolytic Tinplate Sheets for Food Tin Packing Description

Electrolytic Tin Plate Coils and Sheets for Foods Metal Packaging, is one thin steel sheet with a coating of tin applied by electrolytic deposition. Tinplate made by this process is essentially a sandwich in which the central core is strip steel. This core is cleaned in a pickling solution and then fed through tanks containing electrolyte, where tin is deposited on both sides. As the strip passes between high-frequency electric induction coils, it is heated so that the tin coating melts and flows to form a lustrous coat.

2.Main Features of the Electrolytic Tinplate Sheets for Food Tin Packing

Appearance – Electrolytic Tin Plate is characterized by its beautiful metallic luster. Products with various kinds of surface roughness are produced by selecting the surface finish of the substrate steel sheet.

Paintability and printability – Electrolytic Tin Plates have excellent paintability and printability. Printing is beautifully finished using various lacquers and inks.

Formability and strength – Electrolytic Tin Plates have got very good formability and strength. By selecting a proper temper grade, appropriate formability is obtained for different applications as well as the required strength after forming.

Corrosion resistance – Tinplate has got good corrosion resistance. By selecting a proper coating weight, appropriate corrosion resistance is obtained against container contents. Coated items should meet 24 hour 5 % salt spray requirement.

Solderability and weldability – Electrolytic Tin Plates can be joined both by soldering or welding. These properties of tinplate are used for making various types of cans.

Hygienic – Tin coating provides good and non toxic barrier properties to protect food products from impurities, bacteria, moisture, light and odours.

Safe – Tinplate being low weight and high strength makes food cans easy to ship and transport.

Eco friendly – Tinplate offers 100 % recyclability.

Tin is not good for low temperature applications since it changes structure and loses adhesion when exposed to temperatures below – 40 deg C.

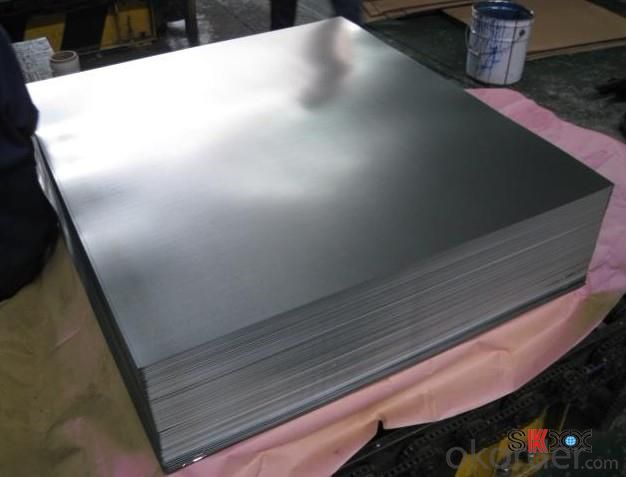

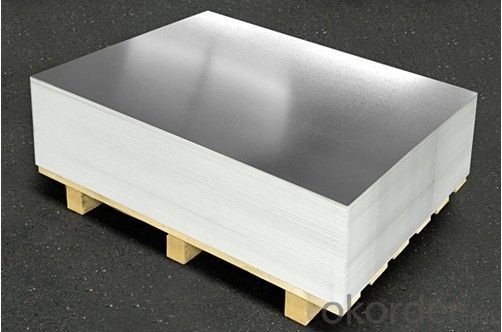

3.Electrolytic Tin Plate Coils and Sheets for Foods Metal Packaging Images

4.Electrolytic Tinplate Sheets for Food Tin Packing Specification

Standard | ISO 11949 -1995, GB/T2520-2000,JIS G3303,ASTM A623, BS EN 10202

|

Material | MR,SPCC |

Thickness | 0.15mm - 0.50mm |

Width | 600mm -1150mm |

Temper | T1-T5 |

Annealing | BA & CA |

Coil Inner Diameter | 508mm |

Weight | 6-10 tons/coil 1~1.7 tons/sheets bundle |

Passivation | 311 |

Oil | DOS |

Surface | Finish,bright,stone,matte,silver |

5.FAQ of Electrolytic Tinplate Sheets for Food Tin Packing

-How to place .an order or contact you ?

Please send us Email. we will give you a quick response in seconds .

- How is your quality ?

All our quality is prime even the secondary quality . We have many years experience

In this field with serious quality control standard . Advanced equipment, We welcome your visit to our factory .

- Q: Can tinplate be used for packaging electronic devices?

- Yes, tinplate can be used for packaging electronic devices. Tinplate is a common material used in the manufacturing of various packaging products, including cans, containers, and boxes. It provides durability, protection against moisture, and electromagnetic shielding, which makes it suitable for packaging electronic devices and safeguarding them during transportation and storage.

- Q: How does tinplate contribute to the overall sustainability of packaging?

- Tinplate contributes to the overall sustainability of packaging in several ways. Firstly, tinplate is a highly durable and long-lasting material, which means that packaging made from tinplate can be reused and recycled multiple times without losing its quality. This helps reduce the need for producing new packaging materials, conserving resources and minimizing waste. Additionally, tinplate is 100% recyclable, meaning that it can be easily recovered and turned into new products, reducing the environmental impact associated with its disposal. Moreover, tinplate offers excellent protection and preservation properties, ensuring the longevity and safety of packaged goods, thus reducing food waste and promoting sustainable consumption. Overall, tinplate packaging plays a significant role in achieving a circular economy by minimizing waste generation, conserving resources, and promoting sustainable practices.

- Q: How does tinplate perform in terms of tamper-evident features?

- Tinplate performs exceptionally well in terms of tamper-evident features. Its inherent strength and durability make it difficult to tamper with or manipulate without leaving clear signs of tampering. Additionally, tinplate can be customized with various tamper-evident mechanisms such as seals, closures, or indicators, further enhancing its reliability as a tamper-evident packaging material.

- Q: How is tinplate used in the construction industry?

- Tinplate is commonly used in the construction industry for various applications. It is often utilized for roofing materials, such as tinplate shingles or metal roof panels, due to its durability, weather resistance, and corrosion protection. Additionally, tinplate is used for cladding or siding purposes, providing an aesthetically pleasing and long-lasting exterior finish for buildings. Its versatility also extends to ductwork, where tinplate is used to fabricate air conditioning and ventilation systems. Overall, tinplate's strength, flexibility, and protective properties make it a valuable material in the construction sector.

- Q: What are the main challenges in tinplate welding and soldering?

- Some of the main challenges in tinplate welding and soldering include ensuring proper surface preparation to achieve good adhesion, dealing with the thin gauge of tinplate which can make it more prone to warping or burning, and finding suitable fluxes and solder alloys that can effectively bond with tinplate due to its unique properties. Additionally, the presence of tin oxide on the surface of tinplate can hinder the formation of strong welds or solder joints, requiring special techniques or treatments to address this issue.

- Q: Cookies with tinplate packaging has what advantage?

- Mature technology and high production efficiency: the production of tinplate has a long history, mature technology is a set of production equipment with matching, high production efficiency, can meet a variety of product packaging needs.

- Q: How does the tin coating affect the weldability of tinplate?

- The tin coating on tinplate actually improves the weldability of the material. It acts as a protective layer, preventing oxidation and minimizing the formation of impurities during the welding process. This results in a stronger and more reliable weld, making tinplate a preferred choice for various applications requiring good weldability.

- Q: Can tinplate be welded?

- Yes, tinplate can be welded. Welding tinplate involves joining two or more pieces of tinplate together using various welding techniques such as spot welding or seam welding.

- Q: What are the safety considerations when handling tinplate?

- When handling tinplate, it is important to consider several safety precautions. Firstly, tinplate can have sharp edges, so it is essential to wear protective gloves to prevent cuts or injuries. Additionally, tinplate may contain sharp metal burrs that can cause cuts or punctures. Therefore, it is advisable to handle the material carefully and avoid dragging or sliding it across surfaces. Furthermore, tinplate is susceptible to rusting, so it should be stored in a dry environment to prevent corrosion. Lastly, tinplate can be heavy, so proper lifting techniques should be employed to avoid strains or back injuries.

- Q: What are the different ways to label tinplate closures?

- There are several ways to label tinplate closures, including direct printing, labeling with adhesive labels, embossing, and laser engraving. Each method offers its own advantages and can be chosen based on factors such as cost, durability, and desired aesthetic appeal.

Send your message to us

Electrolytic Tinplate Sheets for Food Tin Packing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 7000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords