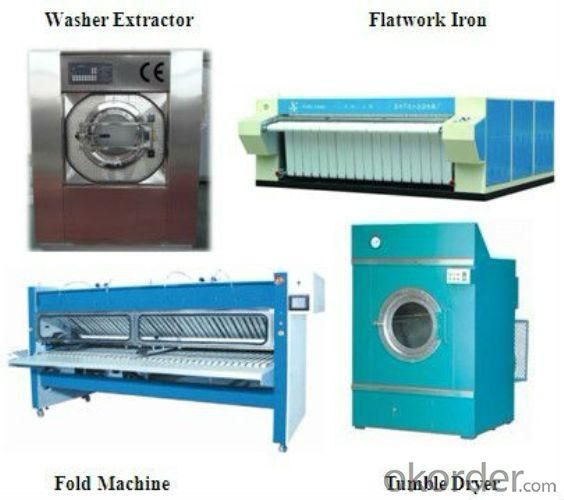

Heavy Duty Washing Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 100 Set Per Month set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications of Heavy Duty Washing Machine

1.heavy duty washing machine from 15kg to 100kg

2.material is Stainless Steel, steam and electric heated , computer control

Packaging & Delivery of Heavy Duty Washing Machine

Packaging Details: wooden

Delivery Detail: 30days when receive the deposit

Technical Parameter of Heavy Duty Washing Machine

| Type | XTQ-15H | XTQ-30H | XTQ-50H | XTQ-70H | XTQ-100H | |||

| Min | 10kg | 20kg | 35kg | 50kg | 70kg | |||

| Max | 15kg | 30kg | 50kg | 70kg | 100kg | |||

| Diameter | 650mm | 902 mm | 1015 mm | 1200 mm | 1200 mm | |||

| Diameter deepness | 450 mm | 500 mm | 610 mm | 626 mm | 785 mm | |||

| Volume | 149 mm | 320 mm | 528 mm | 708 mm | 887 mm | |||

| High | 1510 mm | 1760 mm | 1900 mm | 2300 mm | 2300 mm | |||

| Length | 1010 mm | 1410 mm | 1650 mm | 1850 mm | 1850 mm | |||

| Width | 1110 mm | 1430 mm | 1750 mm | 1800 mm | 2100 mm | |||

| Washing rotate speed | 50r/min | 36 r/min | 35 r/min | 33 r/min | 31 r/min | |||

| Uniformity speed | 90 r/min | 72 r/min | 75 r/min | 70 r/min | 65 r/min | |||

| Mid speed | 450 r/min | 420 r/min | 380 r/min | 350 r/min | 310 r/min | |||

| High speed | 890 r/min | 780 r/min | 760 r/min | 680 r/min | 680 r/min | |||

| Motor | 2.2Kw | 4.0 Kw | 5.5 Kw | 7.5 Kw | 7.5 Kw | |||

| Draining valve | Φ 70mm | Φ 140mm | Φ 140mm | Φ 140mm | Φ 140mm | |||

| Hot water pipe | 3/4″ | 3/2″ | 3/2″ | 3/2″ | 3/2″ | |||

| Cold | 3/4″ | 3/2″ | 3/2″ | 3/2″ | 3/2″ | |||

| Steam pipe | 3/4″ | 1″ | 1″ | 1″ | 1″ | |||

| Power supply | Standard:380+N-3PH-50Hz | |||||||

| Weight | 950kg | 1900kg | 2600kg | 2800kg | 3130kg | |||

- Q: What is the transformation of the textile industry?

- In China, Nike and Kentucky as a household name, if Taiwan from the technical side of the formation of transformation, the United States from the brand side to find the fulcrum. Through the brand, consumers can get a unique interest and experience, rational experience is based on the product, emotional experience is based on emotion. The same piece of clothing, paste the trademark of Nike, the value of immediately jump up, which is competitive!

- Q: What are the hazards of textile warehouses?

- As the stereotypes machine high temperature, accumulation of cashmere, oil and more fire risk is great.

- Q: What is capsule printing and imitation leather printing?

- Single-core with a dye, multi-core with a variety of dyes, composite multi-layer composed of multi-layer composite microcapsules

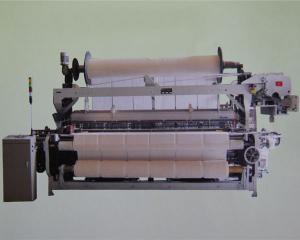

- Q: What is the composition of the loom?

- Multi-color for the weft device: alternating supply of different weft to intertwine, without parking.

- Q: What is the difference between the textile industry and the cotton industry?

- Textile industry in China is a labor-intensive and relatively large dependence on foreign industries. China is the world's largest textile and garment production and exporting countries, textile and garment exports sustained and stable growth to ensure that China's foreign exchange reserves, balance of payments, the RMB exchange rate stability, to solve social employment and the sustainable development of the textile industry is essential.

- Q: What is used textile machinery import clearance process ?

- First determine the customs code (HS) of the equipment to confirm whether to allow imports, whether it relates to imported electromechanical

- Q: How does the shuttleless loom work?

- In the supply of weft yarn, but also directly using the package package, through the weft access device into the weft insertion mechanism, so that the loom out of the frequent twisting action.

- Q: What is the difference between the late Qing machine and the British steam textile machine?

- The shortcomings of hydraulic textile: ① limited to the availability of water resources in the rural areas, but also by the climate and the impact of the season.② factory buildings in the river on both sides of the increasingly difficult transportation .3 where the conditions of construction, the landlord took the opportunity to lift High area of the factory area.

- Q: What is the details of the ginning machine in the textile printing and dyeing industry?

- Metal processing industry: steel plate cleaning production line brush roll coating production line brush brush roll straightening brush brush roller combination brush roll. Polishing cleaning industry: all kinds of polishing with bristles brush sanding machine brush brush washing machine brush brush Cotton cloth round cotton cloth wool wool wheel wool round pig mane wheel wire wheel sweeper box brush road cleaning car manganese steel wire brush and cleaning roller brush disc brush brush brush brush. Scrubber disc brush roller brush, brush barrel machine Brush, planter

- Q: What is the textile handmade textile?

- The original loom was originally directly separated by the fingers of the warp, and later changed to the stick opening and playing latitude. This stick gradually evolved in the shape, thickness and function have a difference, that is, with the comprehensive pole (or heald rod), sub-stick and weaving knife division of labor. The heap is also developed from one to several or ten roots to suit the needs of the weave pattern

We are a well-known enterprise specializing in the production and sales of textile machinery,Since the establishment of our company, we have been devoted to setting up a good quality management system.

1. Manufacturer Overview

| Location | Taizhou, China |

| Year Established | 2003 |

| Annual Output Value | 10-30Setyear |

| Main Markets | Mid East; Eastern Europe; Westen Europen |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 50% |

| No.of Employees in Trade Department | 300 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 28000 square meters |

| No. of Production Lines | Above10 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Heavy Duty Washing Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 100 Set Per Month set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords