Teflon Coated Fiberglass Fabric Roof - High Quality Fiberglass Geogrid for Road

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

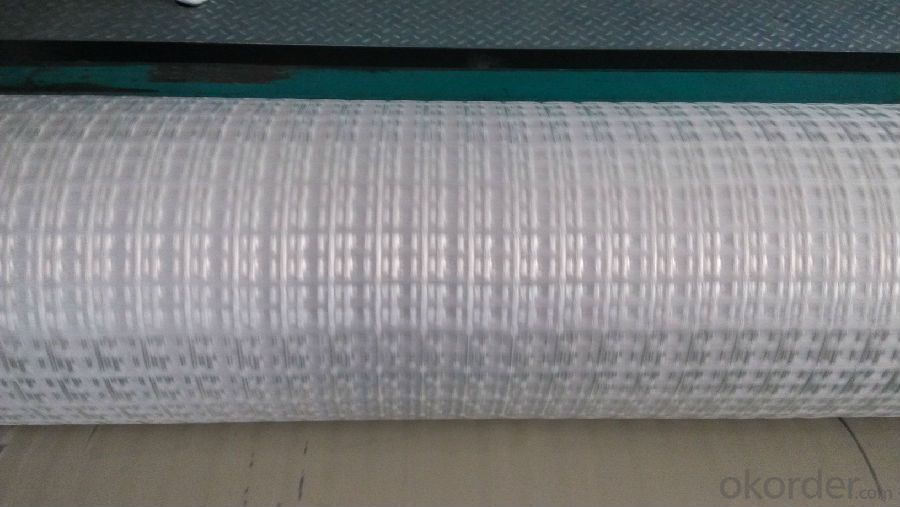

1.Brief Introduction

Product has high strength, low elongation, high temperature, high modulus , light weight , good toughness, corrosion resistance , long life , etc. , can be widely used in the old concrete pavement , maintenance of airport runways , dams , river banks , while slope protection , road bridge , enhancement engineering field, to the road surface can be enhanced , reinforced to prevent pavement rutting fatigue crack , hot and cold telescopic cracks and reflection cracks below , and can the pavement load stress dispersion , extending pavement life .

2.Characteristics

The high tensile strength low - elongation : Fiberglass geogrid is a glass fiber , while the high tensile strength of glass fiber , more than other fibers and ordinary metals . Its high modulus , high resistance to deformation , elongation at break of less than 3% .

3.Application

Physical and chemical stability after special treatment agent coated handle , fiberglass geogrid to resist a variety of physical wear and chemical attack , but also to resist biological erosion and climate change to ensure that its performance is unaffected by the loss .

5.FAQ

Good thermal stability : the melting point of glass fibers is above 1000 °C , to ensure the stability of the glass fiber geogrids to withstand high temperature in a paving job .

- Q: Is fiberglass fabric resistant to chemical degradation?

- Fiberglass fabric is known for its excellent resistance to chemical degradation. Due to its composition of glass fibers, which are impervious to most chemicals, it is highly resistant to the effects of various corrosive substances. Fiberglass fabric can withstand exposure to acids, alkalis, solvents, oils, and other chemicals commonly found in industrial environments without significant degradation. This makes it a preferred choice for applications where chemical resistance is of utmost importance, such as in the manufacturing of chemical storage tanks, pipes, and linings. Additionally, fiberglass fabric's resistance to chemical degradation also contributes to its durability and longevity, making it a reliable material for a wide range of industrial and commercial applications.

- Q: Can fiberglass fabrics be used for reinforcement in wind turbine blades?

- Certainly! Fiberglass fabrics are capable of reinforcing wind turbine blades. They possess numerous properties that render them appropriate for this purpose. Primarily, they exhibit a high strength-to-weight ratio, enabling them to provide exceptional strength without burdening the blades with excessive weight. This is crucial for wind turbine blades, as they must remain lightweight in order to efficiently harness wind energy. Moreover, fiberglass fabrics display exceptional fatigue resistance, which holds great significance for wind turbine blades due to the constant cyclic loading they experience from wind forces. The ability of fiberglass fabrics to endure repeated stress without deteriorating ensures the longevity and durability of the blades. Furthermore, fiberglass fabrics exhibit commendable dimensional stability, meaning they undergo minimal shrinkage or expansion when exposed to temperature fluctuations or moisture. This property is vital for wind turbine blades, as they must maintain their shape and structural integrity in varying environmental conditions. Additionally, fiberglass fabrics are resistant to corrosion, which proves advantageous for wind turbine blades that face harsh outdoor environments with elevated levels of moisture and salt. The corrosion resistance of fiberglass fabrics safeguards the blades against degradation, thereby enhancing their lifespan. To summarize, fiberglass fabrics encompass a range of properties that render them appropriate for reinforcing wind turbine blades. These properties include a high strength-to-weight ratio, fatigue resistance, dimensional stability, and corrosion resistance. Consequently, wind turbines operate efficiently and endure for longer periods.

- Q: Can fiberglass fabric be used for filtration in water treatment plants?

- Filtration in water treatment plants can indeed benefit from the utilization of fiberglass fabric. Renowned for its exceptional durability, high strength, and chemical resistance, fiberglass fabric proves to be an apt choice for filtration purposes. Its efficacy in extracting suspended solids, sediment, and other particles from water guarantees a supply of cleaner and safer water. Furthermore, due to its ability to endure elevated temperatures and pressures, fiberglass fabric is well-suited for the diverse filtration techniques employed in water treatment plants.

- Q: Are there any specific certifications or standards for fiberglass fabrics?

- Yes, there are specific certifications and standards for fiberglass fabrics. One of the most widely recognized certifications for fiberglass fabrics is the ISO 9001:2015 certification, which signifies that the manufacturer has implemented a quality management system and meets the international standards for product quality. In addition, there are specific standards developed by organizations like ASTM International (formerly known as the American Society for Testing and Materials) that outline the testing methods and performance requirements for fiberglass fabrics. For example, ASTM D579-67(2013) provides standard specifications for glass fiber fabrics, while ASTM D3774-16a covers the testing of woven fabrics. Furthermore, there are industry-specific certifications that fiberglass fabric manufacturers may seek, such as the NORSOK M-710 certification for offshore applications or the MIL-STD-810 certification for military-grade fabrics. These certifications and standards help ensure that fiberglass fabrics meet certain quality, safety, and performance criteria. They provide customers with confidence in the product's reliability and help manufacturers demonstrate their commitment to producing high-quality fiberglass fabrics.

- Q: Are fiberglass fabrics resistant to shrinkage or stretching?

- Fiberglass fabrics are known for their resistance to both shrinkage and stretching.

- Q: Can fiberglass fabric be used for making signs and banners?

- Signs and banners can indeed be made using fiberglass fabric. This material possesses various advantages that make it suitable for this purpose. Notably, it is a lightweight and durable option that can withstand different weather conditions and UV radiation. Consequently, signs and banners made from fiberglass fabric can endure outdoor applications and maintain their appearance for an extended period. Additionally, this fabric allows for easy printing, enabling the creation of vibrant and visually appealing designs. Its flexibility also makes it versatile for shaping and manipulating, thus providing numerous options for designing signs and banners. In conclusion, fiberglass fabric is a dependable and efficient choice for creating durable, weather-resistant, and printable signs and banners.

- Q: Is fiberglass fabric resistant to UV rays?

- Indeed, UV rays are unable to penetrate fiberglass fabric. Fiberglass, which consists of a combination of glass fibers and resin, possesses remarkable durability and the ability to withstand various environmental elements, including UV radiation. The glass fibers employed in fiberglass fabric inherently possess resistance to UV degradation, making the fabric highly impervious to the detrimental effects of ultraviolet rays emitted by the sun. As a result, fiberglass fabric has become widely favored for a plethora of applications that are exposed to sunlight, such as outdoor furniture, awnings, boat covers, and other outdoor products. Moreover, the UV resistance of fiberglass fabric guarantees its long-term strength and integrity, even when subjected to extended periods of sun exposure.

- Q: What is the typical weight per square yard of fiberglass fabrics?

- The weight per square yard of fiberglass fabrics can differ based on the fabric's type and purpose. On average, fiberglass fabrics generally weigh between 0.8 and 2 ounces per square yard. This weight can be affected by factors like fabric thickness, fiberglass strand density, and any added coatings or treatments. It's worth mentioning that this weight can also be measured in grams per square meter (gsm) based on regional or industry preferences.

- Q: Can fiberglass fabric be used for making window screens?

- Certainly, window screens can indeed be made using fiberglass fabric. Fiberglass, being a lightweight and durable material, possesses resistance against tears, corrosion, and the harmful effects of UV rays. This outstanding quality makes it an excellent choice for crafting window screens. Moreover, its high flexibility enables effortless installation and removal. In addition to these benefits, fiberglass fabric boasts a fine mesh structure that effectively blocks insects while still permitting airflow and maintaining visibility. All in all, fiberglass fabric is widely favored and considered a dependable option for producing window screens.

- Q: What is the weight of fiberglass fabric?

- The weight of fiberglass fabric can vary depending on the specific type and thickness, but generally, it is lightweight and typically ranges from 3 to 10 ounces per square yard.

Send your message to us

Teflon Coated Fiberglass Fabric Roof - High Quality Fiberglass Geogrid for Road

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords