Machine Length Tan BOPP Packing Tape with Water Based Acrylic OPP Adhesive Tape

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 50000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Material | BOPP film+pressure-sensitive glue |

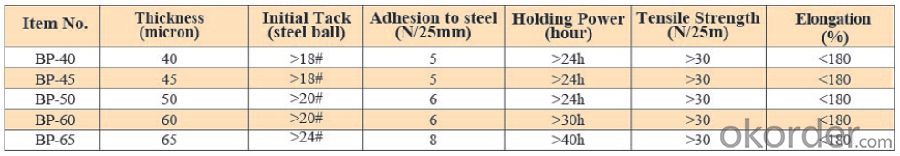

Total Thickness | 35mic-65mic |

Width | 10/11/12/15/17/18/24/30/40/42/45/46.5/48/50/50.4/52.5/55/57/60/72mm |

Length | 30y-1000m |

Tensile | above360N/25mm |

Adhesion | above25N/25mm |

Initial Adhesive | 20-24# |

Color | Clear, white, yellow, red, blue, green, etc |

Tape Paper Core | 2.5/ 2.8/ 3/ 3.5/ 4/ 4.5/ 5/ 5.5/ 6 mm |

Jumbo Roll | 1280/980/960mmX4000m |

Available in maximum four colors print by Rotogravure Prints.(empty printing, full printing) | |

Payment | T/T(30% deposit, and the balance upon the copy of B/L ) |

L/C(30% deposit, the balance by L/C at sight ) | |

Main Market | North America/Asia/Western Europe/South America/Africa |

Certifications | CTI(TPCH,RoHs) |

MOQ | 5000rolls |

Product Discription

Applications:

Shipping, packaging, bundling, wrapping.

Ideal for sealing of cartons, merchandise, pallets

Excellent performer for both hand and machine application.

Advantages:

Characteristic:Strong adhesion,good for packing ,easy tear, low odor

Material:BOPP with high tension strength, good quality glue .

OEM Offer:The tape can be made as your request(weigh,length,microns,color,paper core etc)

Management:Has many firstlevel manager,and control the quality in the process of the production.

Glue store :Can store over 220T glue for one-time

FAQ:

1. Q:Can we order the customized logo tape?

A: Yes, we can offer the customized logo tape.

2. Q: Are you sure about the quality and length?

A: We are factory, Quality is the best advertisement. we can sure you about the quality and length.

3. Q:Can you make our logo on the paper core of the tape?

A:yes,we can help to print. and the mould cost will be $50. If the quantity is 300 cartons, then will be free of logo charge.

- Q: Does packaging tape have a specific weight capacity?

- Yes, packaging tape generally does not have a specific weight capacity as it is primarily used for sealing and securing packages rather than providing structural support.

- Q: Is packaging tape safe to use on plastic picture frames?

- Yes, packaging tape is generally safe to use on plastic picture frames. Packaging tape is designed to be strong and durable, making it suitable for securing items, including plastic frames. However, it is important to consider a few factors before using packaging tape on plastic picture frames. Firstly, ensure that the tape does not have any adhesive that could potentially damage or leave residue on the frame. It is advisable to test a small, inconspicuous area of the frame with the tape before applying it to the entire frame. Additionally, when removing the tape, do so carefully to avoid any potential damage to the frame. Overall, as long as you exercise caution and choose an appropriate tape, packaging tape should be safe to use on plastic picture frames.

- Q: Is packaging tape heat resistant?

- Yes, packaging tape is typically heat resistant. Most packaging tapes are made from materials such as polypropylene or vinyl, which can withstand moderate temperatures without melting or losing their adhesive properties. However, it is important to check the specific specifications and limitations of the packaging tape you are using to ensure it is suitable for your intended application.

- Q: Can packaging tape be used for sealing glass containers?

- Indeed, glass containers can be sealed using packaging tape. Packaging tapes are specifically engineered to offer a robust and reliable seal on diverse surfaces, glass included. When applied correctly, the tape adheres firmly to the glass, forming a secure seal that safeguards the container's contents. Nonetheless, it is crucial to acknowledge that not all packaging tapes are suitable for glass containers. It is advisable to utilize a tape explicitly designed for glass or a heavy-duty packaging tape with exceptional adhesive properties to guarantee an effective seal.

- Q: Can packaging tape be used for sealing plastic storage bags?

- Yes, packaging tape can be used for sealing plastic storage bags. It provides a strong adhesive bond that helps keep the bags securely sealed.

- Q: Is packaging tape safe to use on plastic cutting mats?

- Yes, packaging tape is generally safe to use on plastic cutting mats. However, it is important to ensure that the adhesive used in the tape does not contain any harmful chemicals that could potentially damage or contaminate the plastic surface of the cutting mat. It is recommended to check the manufacturer's instructions or do a patch test on a small area of the mat before applying the tape extensively.

- Q: Can packaging tape be used for sealing packages with confidential or sensitive contents?

- Packaging tape can be used for sealing packages with confidential or sensitive contents, but it is not the most secure option. For enhanced security, it is advisable to consider using tamper-evident or tamper-resistant packaging solutions, such as security tape or specialized envelopes, to provide an additional layer of protection against unauthorized access or tampering.

- Q: Can packaging tape be used for sealing protective packaging materials like bubble wrap?

- Indeed, bubble wrap can be effectively sealed with packaging tape. The purpose of packaging tape is to establish a robust and secure seal on diverse materials, bubble wrap included. In the packaging and shipping sectors, it is widely employed to guarantee the safety and security of package contents throughout transportation. To ensure optimal protection and prevent any potential harm or exposure, it is essential to apply the tape along the edges of the bubble wrap, creating a snug seal.

- Q: What are the alternatives to packaging tape for sealing packages?

- There are several alternatives to packaging tape for sealing packages. Here are a few options: 1. Gummed tape: Gummed tape, also known as water-activated tape, is a popular alternative. It is made of paper or reinforced material and requires water to activate the adhesive. Gummed tape forms a strong bond with the package and provides a tamper-evident seal. 2. Strapping: Strapping is commonly used for securing heavy or bulky packages. It involves using plastic or metal straps to hold the package tightly together. Strapping can be more secure than tape, especially for larger or irregularly shaped items. 3. Shrink wrap: Shrink wrap is a plastic film that can be wrapped around the package and sealed using heat. As the film shrinks, it tightly conforms to the shape of the package, providing a secure seal. Shrink wrap is commonly used for wrapping pallets or bundling multiple items together. 4. Adhesive labels: Adhesive labels can be used as an alternative to tape for sealing packages. These labels have a strong adhesive backing that sticks to the package, providing a secure seal. They are especially useful for small or lightweight items. 5. Twine or string: For lighter packages, twine or string can be used to secure the contents. Simply wrap the string around the package multiple times and tie it securely. While this method may not be as strong as tape, it can be a cost-effective and eco-friendly option. Ultimately, the choice of alternative to packaging tape depends on the size, weight, and nature of the package. Each option has its own advantages and disadvantages, so it's important to consider the specific requirements of the shipment before making a decision.

- Q: Can packaging tape be used for sealing gardening or outdoor equipment?

- Indeed, gardening or outdoor equipment can be effectively sealed using packaging tape. Specifically engineered to securely seal boxes and packages, packaging tape proves itself as an excellent option for sealing outdoor gear like gardening tools, outdoor furniture, and other equipment. Its robust and long-lasting seal is capable of enduring outdoor conditions, including moisture and temperature fluctuations. Nevertheless, it is worth mentioning that if the equipment or packaging tape is expected to endure harsh weather conditions or prolonged outdoor usage, opting for specialized outdoor or weather-resistant tape would be more suitable to ensure enhanced durability and longevity.

Send your message to us

Machine Length Tan BOPP Packing Tape with Water Based Acrylic OPP Adhesive Tape

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 50000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords