Swivel Scaffolding Swivel Couplers with Perfect Performances

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 16000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Timber-beam Formwork

.Timber beam wall formwork is used for the concrete pouring of wall. The application of large areas formwork has greatly increased the construction efficiency and reduced the cost.

. The system is convenient for construction and it is easy to control the quality.

.The system has two parts, formwork and pull-push props. The formwork is made of plywood, timber beam and steel waling. Pull-push props can be designed according to the project or simply select the standard props. Tie-yoke and tie-rod are used to reinforce the corner.

2. Main Features of Timber beam wall formworks

-convenient for construction

-easy to control the quality

-easy, rapid and economical.

3. Timber beam wall formwork Images

4. Timber Beam Wall Formwork Specifications

Timber beam column formwork is used for the concrete pouring of square or rectangle column. The system has the same structure and similar connection type with wall formwork.

5. FAQ of Timber-beam Formwork

1) What can we do for you?

.We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in Timber-beam Formwork, please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Timber-beam Formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: As Customer's Requirements

.Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

.Shipping time:

Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

Other mass qty of Timber-beam Formwork, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

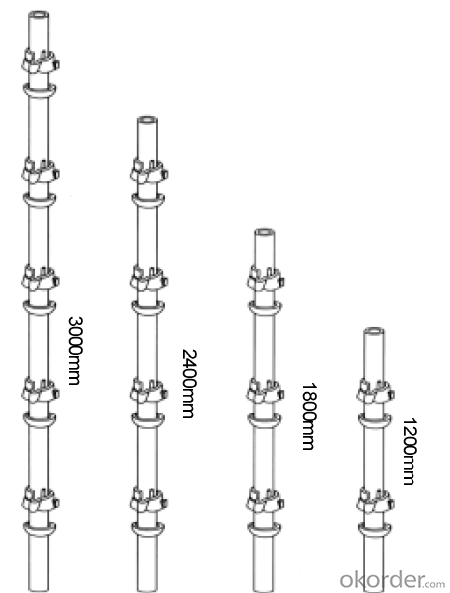

- Q: Said chrysanthemum disc scaffolding system, disc scaffolding system, wheel type scaffolding system, buckle scaffold, layher frame

- Crossbar HG-30 3001.67HG-60 6002.82HG-90 9003.97HG-120 12005.12HG-150 15006.28

- Q: Scaffolding installation and precautions?

- Began to set up the column, should be set up every 6 span of a throw support, even after the installation of the wall is stable, can be removed according to the circumstances.

- Q: Which kind of scaffolding is the most convenient and time-saving?

- The advantages of the new scaffold (compared with the bowl button) are as follows:1, with sufficient mechanical strength, stiffness and stability, safe and reliable work.2, the node connection without frame degree, has the ability to self lock, installation and disassembly flexible and quick, easy to grasp, support, removal efficiency than the bowl buckle type multifunctional scaffolding about three times, can save labor, labor, save time. In the process of construction, opening and closing channels at any time.

- Q: I would like to ask how much scaffolding steel prices, scaffolding steel pipe use what are the requirements?

- Hello, you ask this question is not answered, you are building it, I am here to help you check a lot of information on the Internet, here to share with you, you can look at the reference price, the price there is no uniform standard, each region is different, the price is for reference only. Practice has proved that the new scaffold not only safe and reliable construction, installation speed, and the amount of steel scaffolding can be reduced to 33%, disassembly efficiency is improved by more than two times, the construction cost can be decreased, the construction site civilization, clean and tidy.

- Q: A 520 kg box sits 1.4 m from the left end. What is the tension in the right hand side wire? (g = 9.8 m/s2) ____________ Newtons

- Because the scaffold is not moving, we can assume that the net Torque acting on the scaffold equals zero. Net Torque = 0 torque = Force x distance (d) Use the left end of the scaffold as the center point. This will eliminate the Torque caused by the left wire (d = 0, so torque = 0) There are now three forces creating torque on the scaffold. There is the weight (m x g) of the scaffold, at 3.5m from the left end. m1 x g x 3.5m There is the weight of the crate, located 1.4m from the left end: m2 x g x 1.4m These two torques are countered by the torque caused by the Tension (T) of the right wire, located 7m from the left side. T x 7m The sum of these torques is zero. (T x 7m) - (m1 x g x 3.5m) - (m2 x g x 1.4m) = zero solve for T T = ((m1 x g x 3.5m) + (m2 x g x 1.4m)) / 7m T = ((115kg x 9.8m/s^2 x 3.5m) + (520kg x 9.8m/s^2 x 1.4m)) = 1.58 x 10^3 N Hope this helps.

- Q: Okay so I got a scaffold piercing about 5 days ago now. I've been cleaning it with Claire's piercing stuff. What I do is I pour it onto a little bit of loo roll and squeeze it all out on where the holes are. I have not been twisting it at all, but my friend told me that I should soak it in warm salty water and twist it twice a day. I have no idea what to do now as I have researched it and some people say that I shouldn't twist it because it will drag more bacteria into it and could get it infected. Also I have massive scabs around both ends of the bar, I've tried to pick them off as they are pretty uncomfortable, but it didn't work as they are rock solid, so how do I get these off? I have no idea what to do, my piercer didn't say anything about twisting it just cleaning it twice a day. Oh and if it helps I'm 13:) Thanks. X

- Why are you using Claire's crap? You need to be doing sea salt soaks twice a day for 5-10 minutes each soak with 1/4th of a teaspoon of non-iodized sea salt to 8oz of hot water. Don't twist them as that drags in crust and bacteria and tears up the inside of the piercing. Stop trying to pick stuff off from your ear and go have a reputable piercer check out the scabbing, it could be crust it could be something wrong. If your piercer didn't tell you to do sea salt soaks to keep it clean go to a better piercer.

- Q: how did they turn the cells into a polymer for the heart scaffold ?

- May have misunderstood. The heart is gently stripped of cells by using a detergent - this leaves the extracelllular matrix - a polymer of collagen - inert and insoluble. New cells (stem cells) will then be added to the structure to repopulate it with living heart muscle which gain coordination and structure from the matrix.

- Q: Fastener type steel pipe scaffold composed of which components?

- 3.3 foot plate3.3.1 foot plate can be made of steel, wood, bamboo materials, the quality of a single foot board should not be greater than 30kg.3.3.2 stamping steel feet of the material should be consistent with the existing national standard carbon structural steel GB/T700 Q235Class steel provisions.3.3.3 wooden foot plate material should be consistent with the current national standard "wood structure design code" GB50005 IIaMaterial requirements. Foot plate thickness should not be less than 50mm, both ends should be set to the diameter of not less than 4mm platingZinc wire hoop two.3.3.4 bamboo scaffold board shall be adopted by bamboo or bamboo bamboo string plate, bamboo; bamboo string amphipodsshouban shouldIn accordance with the existing industry standards "construction of wood Scaffolding Safety Technical Specifications" JGJ 164 of the relevant provisions.3.4 adjustable support3.4.1 adjustable support screw outer diameter shall not be less than 36mm, diameter and pitch should be in line with the current national standard "ladder"Type screw thread GB/T 5796.2, GB/T 5796.3 provisions.

- Q: I'm interested in a scaffold career in the oil rigs in the north sea

- Sorry if I'm not serious, but go to Hong Kong as there they do scaffolding made of bamboo and 170 floors high ,2000mtrs above the sea level... Now that is serious...

- Q: What are the safety requirements for the dismantling of construction scaffolding

- (5) remove the material, structural parts, etc., it is strictly prohibited to throw down, the use of rope tied firmly slow down, or with a crane, basket and other means of transport to the ground.(6) the scaffolding removed, should make clear the workplace after work, all materials and components should be neatly stacked, safe and stable, and timely transport.

Send your message to us

Swivel Scaffolding Swivel Couplers with Perfect Performances

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 16000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords