Steel Tile Roll Forming Machine Manufacturer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 PCS

- Supply Capability:

- 100 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

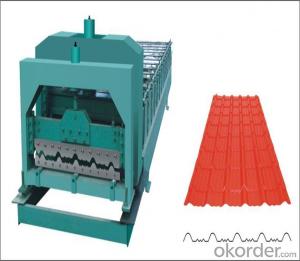

1.Structure of steel tile roll forming machine:

Steel tile roll forming machine consists of feeding, forming, after forming cutting production of color plate smooth appearance beautiful appearances, uniform lacquer veins, high strength, durable, widely used in industrial and civil buildings, such as workshop, warehouse, gymnasium, exhibition halls, theaters and other surface and wall.

2.Main Features of the steel tile roll forming machine:

The tile roll forming machine has the advantages of good corrosion resistance, colorful, beautiful appearance, convenient processing molding and the advantages of the the original strength of the steel plate and the cost is low.

First generation and second generation "automatic moulding color tile equipment" adopt "swinging cylinder driving sliding table", "swinging cylinder" belong to "moulded caigang watts equipment" is "extremely fragile" in accessories, if the forming speed is too fast, cause a large sliding table shock, buffer vibration easily, cause the tiles have crack, is the first and the second generation "stubborn" in the color tile equipment. So the fastest forming up to 6 pieces per minute.

3.Steel tile roll forming machine Images

4.Steel tile roll forming machine Specification

Steel tile roll forming machine has a lot of parameters to set, by using the text screen or touch screen setting. Parameter setting, which has two kinds of equipment parameters and user setting.

Equipment parameters: single pulse length, impulse, molding, molding time, cutter and so on.

User parameters: the number, length, pitch, the first section, small section, section number, preloading and so on.

Main moter power 5.5KW

Hydraulic station power 4KW

Hydraulic oil pump CB-E310

Sprocket P-25.4

Roller station 13

Yield strength 32MPa

Diameter of principal axis 90MM

Material of roller 45#steel hard chrome plating

Processing speed 10-15m/min

Thickness 0.3-1.2 mm

Installation dimension about(L*W*H) 7.5*1.3*1.5M

Total weight 4.2T

Equipment parts includes:roll forming system, hydraulic system, PLC frequency conversion control system, counter, cutting system,decoiler .

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

1). What’s your machine installation & commissioning, training:

1or2 technicians will be dispatched to Buyer’s plant for installation & commissioning. Work period: in 5 days. The expense of round trip tickets, accommodation, safety and interpretation shall be covered by Buyer, additional pay allowance to the technicians.

2). Can you make machine according to my design?

Yes, we have experienced technical team to work out the suitable design for you and confirm with you until you agree.

3). What is the warranty for our machine?

We have one year guarantee, and provide whole life's technical support.

4).Is the machine automatic?

Yes, it can be manual and automatic.

5).what policy for broken parts?

within one year,we offer free parts. If beyond one year,you need to buy by factory cost

- Q: What raw materials and equipment do you need for your own admixture?

- The admixture of concrete mixing station using a lot of more phyletic, the effect is different also, early strength agent, retarder, water reducing agent, and release agent, antifreeze, etc., which is a kind of do not know you to call. The admixtures are usually made by professional manufacturers, and the ingredients are not the same.

- Q: What kind of sand do you need for a concrete plant? I don't know where to start!

- It's usually in the middle of the two, between 2.3 and 3.0 and of course the fineness modulus between 2.3 and 3.0 is the best of the two and that's the best way to get the kind of sand that you want to do to help you

- Q: What type of concrete mixer is needed for each hour of concrete 90 cubic meters?

- Many manufacturers will say that the HZS90 station is the one that makes 90 square concrete. In fact, the HZS90 station is supposed to produce 90 square concrete when it is in theory, and it is actually not up to 75 square

- Q: Cement warehouse introduction, storage reserves?

- This one has a lot of small, see how to configure, usually at 200 tons above each warehouse

- Q: How much concrete is produced per hour by HZS180 concrete mixer?

- Depending on the different areas of the site, the requirement is between 10 and 300, 000, which requires a high level of testing equipment. The cost is relatively higher. The best way is to find a few different test equipment suppliers, according to different manufacturers, equipment, and make a simple quote analysis

- Q: How much water does a concrete mixer use every day?

- It is also a waste of water to flush the transports. Suppose you flush a vehicle with 1-2t water, rinse it 2-3 times a day, and use 20 cars a day for a medium size of a blender, 40 to 120 t a day. From this perspective, the reuse of washing water is very conducive to environmental protection and water conservation. The rational recycling of water in the mixing stations is also gradually being promoted. Our new hydraulic patent product concrete wastewater and sewage circulation recycling used by many domestic manufacturers, most of new mixing plant began to use the recycling equipment. The wastewater recovery system has made some efforts for the environmental cause of China.

- Q: How to choose a good concrete mixer station?

- Selection is best good survey is supply and demand situation of you and how many mixing station, concrete demand how, don't blindly pursuing big equipment, vehicles and personnel left unused, but it is now generally good, as long as the operation, mixing station not at a loss

- Q: How long does it take to build a concrete mixer station?

- The core part of the stirring station: stirring the host, electronic control system, weighing element and instrument. The mixer should choose to use the stirring stability, the maintenance is simple and convenient, the service life is long, the match is supplied with the sufficient production plant. The electric component must choose the international brand products, preferably the imported original product, to guarantee the reliable; The software of the computer system shall be developed by the manufacturer in order to be upgraded and replaced in the future. And there should be a pro version of the software (piracy is prone to malfunctions and possible intellectual property lawsuits).

- Q: How much concrete is produced by the js1000 type of the concrete mixing station

- The production standard test concrete is not less than 50 cubic meters per hour. But the actual situation is (fully automatic), usually more than 40 cubic meters per hour. The cement productivity would be low by hand. Concrete mixing station, also known as concrete mixing station, concrete mixing station is mainly composed of mixing console, materials weighing system, conveying system, material storage system and control system and so on five big systems and other ancillary facilities. Because building aggregate measurement compared with standing aggregate metering, reduced the four of the intermediate links, and the vertical blanking metering, saved measuring time, thus greatly improving the production efficiency, under the condition of the same model, mixing building production efficiency than mixing plant production efficiency by a third. Concrete mixing station is mainly composed of material storage system, materials weighing system, material conveying system, mixing console and electric control system and other ancillary facilities. The mixing and electrical control system is a key part of the whole equipment.

- Q: What is the difference between a concrete mixer and a concrete mixer

- The bone material of the mixing tower is on the top, and the aggregate is measured directly into the mixer. The concrete bin of the commercial concrete station is below, and the bone material is measured and then transported into the mixer after being transported by the inclined belt (which also has some use of the elevator). In a popular way, it is called the building, which is called the second ascent. The steel structure will be larger and the diagonal belt will be relatively longer because of the bone material in the mixing building. But in productivity, the churn is about a fifth higher than the commercial concrete station. In operation, because the inclined belt of the commercial concrete station starts frequently, the energy consumption and the failure rate will increase, and the energy consumption of the mixing building is lower than the failure rate. In the end, because the production capacity of the concrete station is small, the structure is easily disassembled and can be made into a container transfer site, which is suitable for the construction site. The mixing tower is large and high in productivity, and can only be used as a fixed mixer, suitable for the supply of large water projects or large quantities of goods. So customers in the difference between commercial concrete, concrete stand and commodity concrete mixing floor, from aggregate (material), the production efficiency and so on, to choose and buy the right equipment.

Send your message to us

Steel Tile Roll Forming Machine Manufacturer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 PCS

- Supply Capability:

- 100 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords