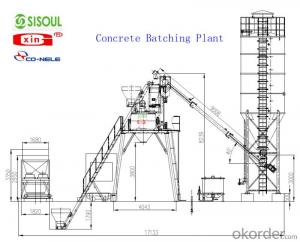

Concrete Batching (mixing) Plant Control System

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 50 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Concrete Batching Plant Control System

ELECTRIC CONTROL SYSTEM

【Software Characteristic】

The control program is developed by ourselves according to requirements of concrete performance, and adhered to practical situation of production process, with all kinds of function.

● 1. Batching process and parameter are displayed on the same interface, and can be modified online.

● 2. Freely setup the a mounts of storage prescription. You can choose several prescriptions at the same time, shift them freely and modify the data online.

● 3. Adopt the technology of double speed feeding and automatic fall compensation so as to ensure weighing precision of each batch.

● 4. The parameter such as rate of water content, interval between door opening and closing, can be modified online.

● 5. The system can inspect main parameters intelligently, so it will prevent some mistakes caused by mistake input.

● 6. There is double-computer and double-control mode, so you can choose any control.

● 7. The system has perfect functions of data finding and printing.

【Hardware Characteristic】

◆ The electric parts we choose are famous international brand Schneider/Siemens, with high quality and reliable performance.

◆ The industry control computer and A/D card are made by Yanhua, and have good performance with environment, which can ensure safety in production.

◆ The imported sensor and meter have a reliable performance on inputting and dealing with data. Meanwhile, it is to operate them and safe to use.

◆ The console is designed elaborately which suits body structure, so you would feel comfortable and happy during work.

◆ Excellent protection makes maintenance and debugging easy and safe operation.

- Q: What kind of sand do you need for a concrete plant? I don't know where to start!

- Give you a website to see. Specializing in concrete mixing stations. Hope that useful.

- Q: What is the concrete of the mixing station?

- I am at the work station, the concrete mixing plant is operating goods, use the material such as cement, fly ash, sand, water reducing agent in strict accordance with the provisions of the state standard the ratio of mixing, through concrete truck mixer (commonly known as "car" river) transportation to the construction site, recycled concrete pump for handlebar concrete on the building site. For building products safety, now the big building construction are banned to mix concrete, concrete supply must to the recognition of concrete mixing station to buy, hope to help you.

- Q: What type of concrete mixer is needed for each hour of concrete 90 cubic meters?

- If it's a theoretical one, it's going to build 90 lines per hour, which is 90 square hours per hour, and if it's actually 90 square, it's going to be at least 120 stations.

- Q: What is the concept of on-site concrete mixer station

- Concrete mixing station is mainly composed of mixing console, materials weighing system, material conveying system, material storage system and control system of large system and other ancillary facilities. Action: concrete mixing plant is used to concentrate the mixing of concrete, also called concrete precast. Because its mechanization, high degree of automation, productivity is high, and can guarantee the quality of concrete and cement, commonly used in concrete, long duration and site of quantities focus of large and medium-sized water conservancy, electric power, Bridges and other projects. Centralized with the development of municipal construction, stirring, provide commercial concrete mixing station has great advantages, and thus get rapid development, and to promote concrete pumping construction, the mixing, transportation, casting machinery joint operation to create the conditions. Basic introduction: concrete mixing station is mainly composed of mixing console, materials weighing system, material conveying system, material storage system and control system of large system and other ancillary facilities.

- Q: How much water does a concrete mixer use every day?

- It is also a waste of water to flush the transports. Suppose you flush a vehicle with 1-2t water, rinse it 2-3 times a day, and use 20 cars a day for a medium size of a blender, 40 to 120 t a day. From this perspective, the reuse of washing water is very conducive to environmental protection and water conservation. The rational recycling of water in the mixing stations is also gradually being promoted. Our new hydraulic patent product concrete wastewater and sewage circulation recycling used by many domestic manufacturers, most of new mixing plant began to use the recycling equipment. The wastewater recovery system has made some efforts for the environmental cause of China.

- Q: How to choose a good concrete mixer station?

- The concrete mixing station of choose and buy should focus on quality and quantity. Some users choose and buy when the concrete mixing station, don't know how should choose the equipment, now there are goods on the market of concrete mixing station, concrete mixing station, concrete mixing station. Users should choose different devices and different type of concrete mixing stations according to their own situation.

- Q: What are the ingredients for the concrete mixing stations?

- It is the raw materials for the concrete mixers, the sand, stone, cement, fly ash, mineral powder, various admixtures, water, basically these seven raw materials.

- Q: What are the facilities of the concrete mixing station

- It can be divided into five large parts of the mixing host, material weighing system, material conveying system, material storage system and control system

- Q: Concrete mixstations belong to no special equipment

- Is not mixing station is places or facilities, equipment, for whether the equipment belongs to the special equipment to check the catalog of special equipment, included in the directory is the special equipment, is not included.

- Q: What is the daily routine of the concrete mixing station?

- Your question is fun, you ask is daily work refers to a person or the institution will have job or responsibility, and concrete mixing plant is short for a single search or mixing unit, I put the question to you "what's the concrete mixing station management personnel daily work including".

Send your message to us

Concrete Batching (mixing) Plant Control System

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 50 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords