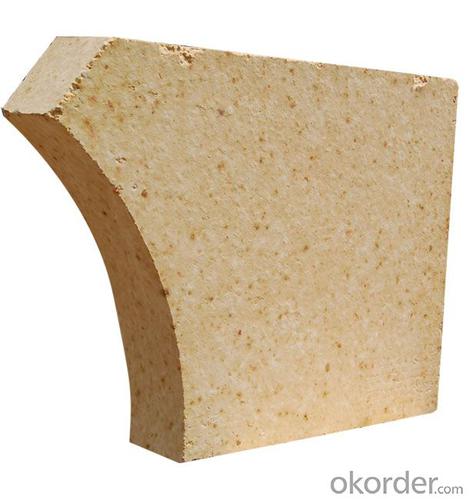

High Alumina Brick for Steelmaking EAF

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

炼钢电炉顶用高铝砖

| |||||||||||||||||||||||||||||||||||

Specifications:

Product features: high alumina brick to select of steelmaking furnace be yangquan super bauxite clinker asthe main raw material, after high pressure forming, high temperature sintering. The main mineral composition as corundum and mullite phase, has excellent high temperature mechanical properties and resistance to chemical attack. Especially not burning products, appearance is more accurate size, good thermal shock stability.

- Q: Density of high alumina bricks

- The density of high alumina bricks is determined according to the price. The average density is between 2.3-2.5g/cm3. The higher the density, the higher the price, the higher the aluminum bricks are in the industry. More than 2.4 are required.

- Q: How are the high alumina bricks fired?

- According to the quality requirements of different grades of high alumina brick, choose different grades of bauxite raw materials, it is conducive to rational use, fine materials, fine distribution, as far as possible not to use mixed grade severe raw materials. The quality of the clinker depends on the calcination temperature, calcination temperature, sintering temperature should be generally reached or slightly higher than that of alumina clinker sintering, to ensure the full and possible high volume density, and the two secondary Mullitization and sintering shrinkage effect in calcination process. Lightweight high alumina brick, also known as high aluminum insulation brick (high-aluminium heat insulating brick). A lightweight refractory consisting of mullite and glass phases or corundum in excess of 48%. The volume density is 0.4 ~ 1.35g/cm3. The porosity is 66% ~ 73%, and the compressive strength is 1 ~ 8MPa. Better thermal shock resistance.

- Q: Aluminum content 38, silicon content 55 What refractory bricks?

- High alumina brick:The mineral composition of the high alumina brick is determined by the bauxite used. The mineral composition of the clinker is usually mullite, corundum and glass. The theoretical composition of mullite is Al2O371.8%, SiO2 28.2%, and its melting decomposition temperature is 1840 DEG C. With acicular crystal, network cross structure, high temperature state showed better strength. Corundum in the form of alpha -Al2O3, melting point of 2050 degrees, hardness of Mohs 9, showing a granular and columnar crystal, has good chemical stability, acid, alkaline slag have a certain resistance. Based on the composition of mullite minerals, the phase composition of high alumina brick can be judged according to the content of Al2O3. When the bricks are below Al2O3 71.8%, the base of the composition is mullite and SiO2, such as grade LZ-48 bricks. Because it contains a large number of SiO2 formed in the liquid phase under high temperature is 20% ~ 30%; brick in Al2O3 more than 71.8%, the excess Al2O3 formed corundum crystal under high temperature, while generating 2 high temperature phase, eutectic temperature rise by the low content of Al2O3 brick 1595 C to 1840 C, such as grade LZ-75 brick. In fact, it is impossible to produce a complete phase equilibrium in the process of production, but the glass phase is very small, and there is no more than 10% in the partial gap of the Yu Jing phase

- Q: Corundum, high alumina and fireclay refractory difference is what

- They differ in that the alumina content is different, and the content is in order: corundum > high alumina > clay.

- Q: What are the high temperature refractory mortars made of?

- Products used in metallurgy, building materials, machinery, chemical, power industry, industrial thermal furnace, for masonryBuilding clay brick, high alumina brick and corundum brick have the characteristics of full grey seam, good airtightness, high bonding strength, high temperature performance and suitable construction time

- Q: What's the weight of the refractory bricks?

- Fireclay refractory bricks: 3.4kg-3.8kg - according to the quality of raw materials, prices ranging from 1 yuan to 2.7 yuan, high alumina refractory brick: three, high aluminum in 3.9kg or so. Ordinary T-3 firebrick weight calculation method: 230*114*65*2.2/2.1.

- Q: What is the apparent porosity of high alumina brick?

- Total porosity is porosity refers to the total volume of sample porosity in the percentage of total volume of samples. Apparent porosity refers to the percentage of the total volume of openings, pores, and total specimens in the sample.

- Q: What kind of material is the general metal case?

- Generally speaking, the outer surface of the case is usually made of a steel plate of more than 1 millimeters. The thickness and the material of the steel plate are directly related to the rigidity of the case, as well as the capability of sound insulation and anti electromagnetic radiation. The regular manufacturers of the chassis plate thickness not less than 1.3mm, but there are also some small manufacturers with a thickness of only about 1mm steel, we do not need the ruler to the amount, as long as you put him up, the more weight in the same volume of the chassis is better, in addition, we can also use the finger bomb case shell. If you can hear the crisp percussion sound proof of the casing plate is thin and brittle, if you hear is relatively dull and heavy sound that the chassis material must be good, good general steel plate coated with a layer of thin zinc (bright part), so it can withstand high strength, impact resistance, hardness high elasticity. The frame parts of the chassis are made of high quality materials with high hardness. They are bent into angle shapes or strip shapes. We can shake the chassis frame of the case by hand. Good chassis should be relatively stable, and inferior chassis light is easy to shake. When choosing, we should also pay attention to the outer edge of the case and the edge of the inner bracket. Whether the incision is smooth or not, a good case will not appear in the case of rough edges, sharp edges, burrs and so on. While the poor case appears above phenomenon, often appear when installing the blood splattered". Generally speaking, the chassis must go through the corresponding grinding process before leaving the factory. The edge of the flat plate some burr, edges and corners are rounded, the corresponding fold some corner. When you install such a case, you don't worry about cuts, and some rough, poorly built cabinets tend to scratch your hands.

- Q: Is glass wool inorganic thermal insulation material?

- The characteristics of glass wool, glass wool is the molten glass fibrosis, the formation of cotton like material, chemical composition of glass, is a kind of inorganic fibers. With good forming, small volume density, thermal conductivity, both thermal insulation, sound-absorbing performance, corrosion resistance, chemical stability.

- Q: What are the categories of bricks?

- In a proper ratio of lime sand brick and quartz sand, sand or fine sand, the ground, Kazumi Wa, semi dry pressing and autoclaved curing and. The fly ash brick is made of fly ash as main raw material and mixed with cement material such as coal gangue, stone powder or clay. It is made up of batching, molding, drying and roasting. It can make full use of industrial waste residue and save fuel.

Send your message to us

High Alumina Brick for Steelmaking EAF

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords