Steel Coupler Rebar Scaffolding Tube Made as Good Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Coupler Rebar Scaffolding Tube High Quality

1.Description of Steel Coupler Rebar Scaffolding Galvanized Scaffolding Tube:

Lapped joints are not always an appropriate means of connecting rebar. The use of Steel Rebar Couplers can simplify the design and construction of reinforced concrete and reduce the amount of reinforcement required.

The threaded steel coupler system is designed as a threaded reinforcement connection with 100% load transmission. The steel coupler rebar connection system is suitable for both static and dynamic load transmission in construction joints.

The coupler is designed as a threaded reinforcement connection for formed construction joints. Reinforcement work is normally carried out on both sides of the construction joint using lap joints or one side is anchored. The bar lengths are based on the structural analysis requirements of the building component and are calculated from anchorage and lap lengths.

2.Advantages of Steel Coupler Rebar Lift Scaffolding Galvanized Scaffolding Tube:

Advantages of Cut and Bend Services

Rebars are cut and bent to exact specifications, ensuring precision and consistency.

Cut and bend reinforcement bars do conform to BS 8666.

Material wastage is controlled and reduced.

Lesser on-site labour is required.

Better utilisation of on-site space, logistics and reduction of inventory on-site.

In-house processes and procedures that ensure traceability down to the order level

Weather independent

The coupler system provides the opportunity to connect rebars quickly, easily and cost effectively, even when large rebar diameters are used. This makes the steel coupler rebar range a logical extension to our rebendable CNBM reinforcement continuity system for rebars over 12 mm.

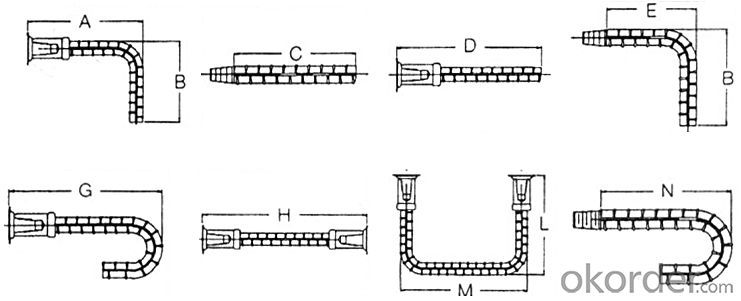

3.Available sizes of Steel Coupler Rebar Scaffolding Galvanized Scaffolding Tube:

14mm,16mm,18mm,20mm,22mmm,25mm,28mm,32mm,36mm,40mm

4.Delivery:

Delivery Term: FOB / CFR / CIF available.

Delivery Time: 15 days or less after order confirmed.

5.Why choose us?

Technical Expertise

Experienced Management

Stringent Quality Control

Exemplary Service

On-Time Delivery

Wide Product Range

Competitive Pricing

Huge branch network capable of catering worldwide

6.FAQ

Why Us?

We are one of the Top 500 in the world, largest construction materials supplier in China. Also we are a state-owned company and respond to every customer with large and also small orders.

We own professional manufacturers with powerful producing capacity.

Extensive and comprehensive quality control system

Excellent products with competitive prices.

Efficient services in pre and after sale.

Full energy with affluent experience team.

- Q: I've had my scaffolding piercing for about a week now and when cleaning i've just dabbed the hydrogen peroxide and salt water around my ear. However i read that i should be rotating it when cleaning it. Should i rotate it after only a week?

- you dont need to rotate a scaffolding piercing because its in such a place that it will rotate on its own throughout the day/night

- Q: Key points for safety of portal scaffolding

- The main points of the safety of portal scaffolding1, scaffold erection must be held by professional Jia Zigong, and according to the current national standard "special operations personnel safety assessment management rules" (GB5036) qualification certificates. Staff should conduct regular physical examination, which is not suitable for high operator, not on the scaffold.

- Q: What is rolling scaffolding?

- Scaffold (pipe staging) that has wheels in the legs. Any metal scaffolding that you've seen can be fitted with wheels to make it mobile.

- Q: For indoor use of mobile scaffolding safety construction plan! Four support points with four pulleys with brake!The construction scheme of scaffolding safety belt for indoor high Jiqiu braking pulley, for about 12 meters of buildings, indoor emergency please heroes!

- Double pole scaffolding and scaffold for decoration of the vertical distance rod step distance should be less than or equal to 2.0m. peaceFrom the operation layer (floor) scaffold surface height is over 2.0m, the width of working layer deck should not be less than: scaffold for 750mm in scaffolding for the clearance of 500mm. edge of the plank and wall should be more than 300 mm, and blocking foot clearance should be more than 100mm. when the side board is not close to the pole, should with reliable fixation.

- Q: Right! I've heard from so many different people about this. Some say that you should never twist an industrial because it can damage the delicate newly healing skin cells. Others say that you must twist it to prevent the jewelry from healing attached to the skin and to be able to clean it properly.There really doesn't seem to be a definitive answer!My piercer has said not to twist it, so I haven't been, and I'm happy that the piercing is clean enough, etc. However I'm interested in whether any of you out there have found that not twisting it can damage it more than doing so.Thanks

- My piercer told me to move the bar up and down, not to twist it around. And now, it's a year and a few months later and I've never had any problems with mine. It healed perfectly.

- Q: Scaffold removal should comply with those requirements......

- 3 removal of safety technical measures should be made clear to each operator. 4 removal of the scaffolding materials, debris and ground obstacles, and will be affected by the mechanical and electrical equipment and other pipelines, such as removal or protection.

- Q: Okay so I want to get either done, I just want to know which one is more painful. Not felling that nervous because I have had my nose and tongue done. I want to know which one is more painful and how to clean each of them. And also with the lip, is it more like the tongue with what foods you can eat and how hard it is to eat?

- The lip is an interesting piercing. The person doing your piercing will clamp you lip, causing a mild discomfort to distract you and guide the needle and ring in, takes less than a minute. Virtually painless, unless your pain threshold is sensitive. Also, if you get a monroe (left upper lip) or madonna (right upper lip), it would vary from a medusa (center middle lip) because that us where the skin is the thickest. Lower lips piercings are about the same. You start of with a longer laret ring for two weeks to compensate for swelling than get a normal one. It is going inside your mouth so be careful how you chew. m Clean the inside of your mouth after every time you eat with a non alcohol mouth rinse or saltwater rinse. As for the outside take some warm water and non iodized salt and gently twist the labret while using a q tip to gently clean around it.

- Q: Introduction of external scaffolding

- 2 the size and surface quality of steel pipe shall meet the following requirements:1) the new steel pipe should have quality certificate, quality inspection report; steel surface should be flat and smooth, no cracks, scarring, delamination, dislocation, bend, burr, indentation and scratch depth of steel pipe; allowable deviation table item allowable deviation inspection tool 1 welded steel pipe size (mm) diameter 48 wall 3.5 -0.5 thick 2 vernier caliper at two ends of the steel tube shear diagonal deviation 1.7 corner ruler feeler, the outer surface of the steel pipe 3 corrosion depth is less than or equal to 0.50 bar 4 vernier caliper end bend L = 1.5m = 5, 5 pole bending steel ruler 3m<l = 4m4m<l = 6.5m = 12 = 206 level bar, inclined bar bending steel pipe L = 6.5m = 302) from drilling pipe.

- Q: I got my scaffolding approximately about 7 weeks ago maybe just a lil over, I want to know when is a good time to change the bar/take it out, I am keeping up with cleaning it 2 to 3 times a day with the saline solution, even though, it only requires to be cleaned 1-2 times a day to be fair though

- 9-12 months of healing time so 9-12 months until you change it. You should never change an unhealed piercing. Take it from someone who had to retire her industrial piercing from changing it too early, leave it alone until it is 100% healed.

- Q: male scaffolders only if i was swinging on the scaffold would ya stomp on my fingers with ya workboots on?

- depends how many times have i told you to get off?

Send your message to us

Steel Coupler Rebar Scaffolding Tube Made as Good Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords