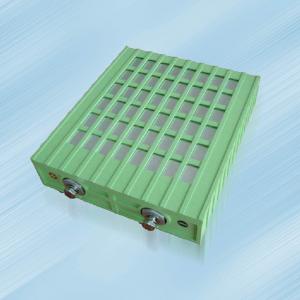

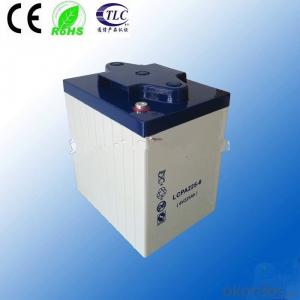

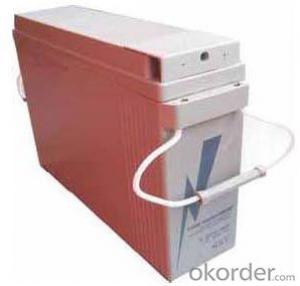

front terminal 12V 100AH high temperature battery

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 24 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Temperature VRLA Batteries, GFMH Series

Overview

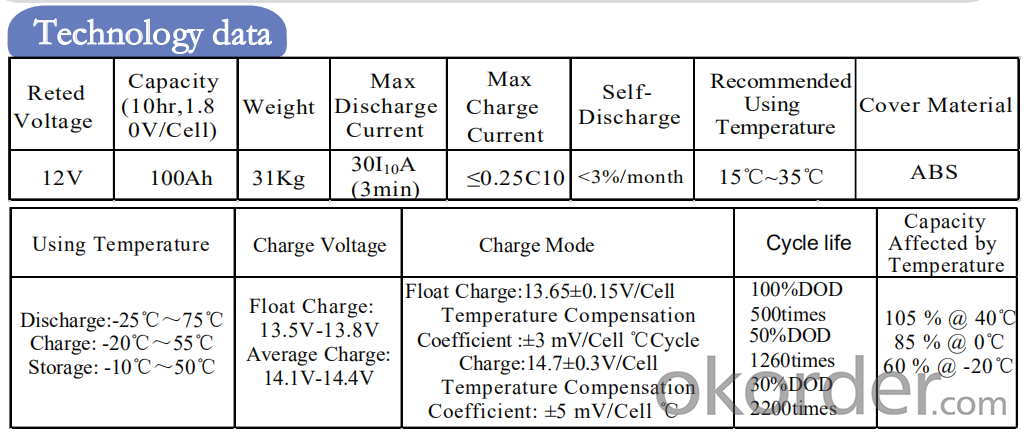

The series of high temperature resistance VRLA batteries, This is used upgraded additives and special high temperature curing process, and it has got long lifetime in the environment of high temperature. The cover of battery is made of synthetic plastic (ABS) with capabilities of anti-fire and high temperature resistance and matches the requirement of 105 ºC. The safety valve is used upgraded rubber head with the max Expansion 3% in high temperature. The design of unique ultra-fine glass fiber separator is effectively anti-water loss. GFMH series battery matches the requirement -25℃-75℃ with long and stable lifetime 15℃-40℃. The high performance & high efficiency is the ideal choice to the extreme environments against communications, electricity and energy storage industry.

Features:

GFMH battery has got wide temperature range and outstanding high temperature performance. It can be used in a range of -25 ℃ ~ + 75 ℃, and it can be long-term use in a range of 15 ~ 40 ℃.

- Q: What is the difference between a maintenance-free battery and a conventional battery?

- As a result of maintenance-free batteries using lead-calcium alloy grille, the amount of water generated when charging less water evaporation, coupled with the shell with a sealed structure, the release of sulfuric acid gas is also very small, so it compared with the traditional battery, With no need to add any liquid, the wiring pile head, wire and body corrosion less anti-overcharge capacity, starting current, power storage time is long, by the car people welcome.

- Q: What are the technical parameters of the battery?

- Usually the capacity of the power supply is expressed by kV · A or kW. However, as a power supply VRLA battery, the use of security (A · h) that its capacity is more accurate.

- Q: How to determine the battery is good or bad?

- Observe the battery electrolyte is turbid, turbidity that the battery positive plate softening. Observe the bottom of the battery whether there is sediment, if the plate off the battery capacity has been inadequate. Hand hit the battery two electrode piles If you hear an empty voice that pole pile and plate break. With a thick wire short-circuit positive and negative pile observation of the battery filling holes, such as the discovery of a bubble appears that the interval has been damaged.

- Q: How to deal with waste batteries?

- The rest of the various types of waste batteries are generally shipped to a special toxic, hazardous landfill, but this approach not only cost too much but also cause waste, because there are many useful raw materials available.

- Q: Maintenance-free battery how to detect it?

- Do not always check the color of the electric eye for maintenance-free batteries. Green for the full power; black for the lack of electricity, need to be added to charge; gray or light yellow for the electrolyte is insufficient, because maintenance-free battery can not add liquid, should immediately replace the battery.

- Q: What battery does the van use?

- The most obvious feature of lead-acid batteries is the top of the plastic cover can be unscrewed, there are ventilation holes above. These fillers are used to fill pure water, check the electrolyte and the use of exhaust gas. In theory, lead-acid batteries need to check the density of each electrolyte and the level of liquid, if there is a need to add distilled water. But with the upgrading of battery manufacturing technology, lead-acid battery development for the lead-acid maintenance-free batteries and colloidal maintenance-free batteries, lead-acid batteries do not need to add electrolyte or distilled water. Mainly the use of positive electrode to produce oxygen can be absorbed in the negative oxygen cycle, to prevent water reduction. Lead-acid water batteries are mostly used in tractors, tricycles, car start, etc., and maintenance-free lead-acid battery wider range of applications, including uninterruptible power supply, electric vehicle power, electric bicycle batteries. Lead-acid batteries according to the application needs to be divided into constant current discharge (such as uninterruptible power supply) and instantaneous discharge (such as car to start the battery).

- Q: What is the meaning of the battery above 12v65Ah?

- 12V is said to be the voltage, 65Ah is the current. (A is the unit of current. H is the time unit .1 hours.)

- Q: What kind of battery is divided into?

- Ordinary battery: ordinary battery plate is composed of lead and lead oxide, the electrolyte is sulfuric acid aqueous solution. Its main advantage is the voltage stability, the price is cheap.

- Q: Battery 200ah / 104 what does that mean?

- 2V battery capacity (from 200AH-3000AH have) long design, good stability, the price is also expensive; 12V battery capacity is generally the largest 250AH, design life as 2V, price economy, high current discharge better.

- Q: How does battery activation work?

- If you are talking about dry batteries, that is, to add sulfuric acid can use the battery (commonly known as water bottles), then it is because the long-term storage so that a high degree of oxidation of the negative board, plus acid will be a high temperature, Low, you can add acid in the pool after the addition of a small current for a long time to charge, you can solve. Generally with 0.05C charge to 3 times can be.

Send your message to us

front terminal 12V 100AH high temperature battery

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 24 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords