Stainless Steel Sheet with Best Quality in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 45555555 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of stainless steel plate:

stanless steel sheet roll

Manufacturer since 2003;

Origin from Baosteel & Tisco;

100% Manufacture's direct deal.

Festures of stainless steel plate:

Material: 201

Finish: 2B, BA, No.4, HL

Thickness: 0.2mm~2.5mm

Size: 1000*2000mm,1219*2438mm or as per customers' request

Application: Kitchenware, decoration, construction and building ornament, product parts manufacturing and stainless steel products tooling and so on

Specifications of stainless steel plate:

Product Name | cr 1219x2438 stanless steel sheet 201 |

standared | JIS, AISI, ASTM, GB, DIN,SUS |

Thickness | 0.2mm~2.5mm |

Size | 1000*2000mm,1219*2438mm or as per customers' request |

Surface finish | 2B, BA, Hair Line, No.1,No.4, Mirror Finish |

Application | Kitchenware, decoration construction and building ornament, product parts manufacturing and stainless steel products tooling and so on |

Payment terms | T/T 30% for deposit, Balance against the copy of B/L; or L/C at sight |

Product Packing | wooden pallet |

Delivery time | within 15-20 working days after we got your 30% deposit |

Attention | FREE SAMPLES can be sent on request. We promise to provide our valued clients with high quality products, low price, and excellent client services. |

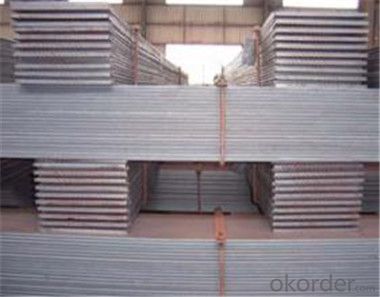

Images of stainless steel plate:

FAQ:

1. What is your package?

Packing situation: standard seaworthy packing or as customer required.

2. How long is the lead time?

Delivery time: 45 days after order confirmed.

3. What payment term do you accept?

Payment: T/T or L/C at sight.

- Q: What are the different types of steel wire rod coatings used for increased strength?

- To enhance the strength of steel wire rods, various coatings are commonly applied. These coatings aim to improve the mechanical properties and overall performance of the wire rod. One frequently used coating for increased strength is zinc coating, also known as galvanizing. This process involves immersing the wire rod in molten zinc, resulting in a protective layer that offers excellent corrosion resistance. Furthermore, the zinc coating acts as a barrier, preventing direct contact with corrosive substances and thereby increasing the wire rod's strength and durability. Another coating option for increased strength is polymer coating. This protective layer is applied to the wire rod through methods like extrusion or electrostatic spraying. It provides resistance against abrasion, impact, and corrosion while also enhancing flexibility and fatigue resistance, ultimately improving the wire rod's overall strength. Epoxy coatings are also commonly used to increase strength. These coatings, composed of a mixture of resin and hardener, are applied to the wire rod's surface through electrostatic deposition. They offer exceptional adhesion and chemical resistance, making the wire rod stronger and more corrosion-resistant. Additionally, ceramic coatings are utilized to enhance the strength of steel wire rods. These coatings are typically applied through thermal spraying techniques, where a ceramic material is heated and propelled onto the wire rod's surface. Ceramic coatings provide exceptional hardness, wear resistance, and high-temperature resistance, making the wire rod more robust and suitable for demanding applications. In conclusion, zinc coating, polymer coating, epoxy coating, and ceramic coating are among the various types of steel wire rod coatings used to increase strength. Each of these coatings offers distinct advantages in terms of corrosion resistance, flexibility, adhesion, and wear resistance, ultimately enhancing the wire rod's strength and durability.

- Q: What are the different types of wire drawing dies used for steel wire rod?

- There are typically two types of wire drawing dies used for steel wire rods: tungsten carbide dies and diamond dies. Tungsten carbide dies are commonly used for drawing steel wire rods with larger diameters, while diamond dies are used for finer wire diameters. These dies help in shaping and reducing the diameter of the wire rods during the drawing process, resulting in a smoother surface finish and improved mechanical properties.

- Q: What are the common industry workshops for steel wire rod?

- Some common industry workshops for steel wire rod include wire drawing workshops, annealing workshops, coating workshops, and testing workshops.

- Q: What are the storage and handling requirements for steel wire rod?

- The storage and handling requirements for steel wire rod include keeping it in a dry and clean environment to prevent corrosion, avoiding direct contact with moisture and chemicals, and ensuring proper ventilation. It should be stored in a well-ventilated area away from sources of heat or open flames. Handling should be done with appropriate lifting equipment to prevent damage. Additionally, steel wire rod should be stored in a way that prevents deformation and maintains its structural integrity.

- Q: How does the thermal conductivity of steel wire rod vary with different heat treatment processes?

- Different heat treatment processes can significantly affect the thermal conductivity of steel wire rod. Heat treatment is a method used to modify the physical and mechanical properties of steel, including its thermal conductivity. One commonly used heat treatment process is annealing. This process involves heating the steel wire rod to a specific temperature and then slowly cooling it. Annealing helps to alleviate internal stresses and enhance the steel's ductility and toughness. In terms of thermal conductivity, annealing can enhance it by reducing impurities and improving the crystal structure of the steel. As a result, there is improved heat transfer efficiency, leading to higher thermal conductivity. In contrast, quenching is a heat treatment process that rapidly cools the steel wire rod after heating it to a high temperature. This process is typically employed to increase the hardness and strength of the steel. However, quenching can also result in a decrease in thermal conductivity. The rapid cooling causes the formation of a fine-grained microstructure, which can hinder heat movement through the material. Another heat treatment process that affects the thermal conductivity of steel wire rod is tempering. Tempering is conducted after quenching and involves reheating the steel to a lower temperature before cooling it again. This process helps to reduce brittleness and improve toughness. Regarding thermal conductivity, the effect of tempering can vary depending on the specific temperature and duration of the process. Generally, tempering can slightly decrease the thermal conductivity of steel wire rod by promoting the formation of small carbide particles, which act as thermal barriers. Overall, the thermal conductivity of steel wire rod can be influenced by different heat treatment processes. Annealing typically increases thermal conductivity, while quenching and tempering may potentially decrease it. The specific parameters of the heat treatment, such as temperature, cooling rate, and duration, play a crucial role in determining the resulting thermal conductivity of the steel.

- Q: How is the tensile strength of steel wire rod tested?

- The tensile strength of steel wire rod is typically tested using a universal testing machine. The rod is securely clamped at both ends, and a gradually increasing force is applied until the rod breaks. The maximum force applied just before the break is measured and used to calculate the tensile strength of the steel wire rod.

- Q: How is steel wire rod used in the manufacturing of wire rope rings?

- Steel wire rod is used as the primary raw material in the manufacturing of wire rope rings. It is first drawn into a wire of the required diameter and then twisted into strands. These strands are then helically wrapped around a core to form a wire rope, which is subsequently shaped into rings. The high strength and durability of steel wire rod make it an ideal material for wire rope rings, providing them with the necessary load-bearing capacity and resistance to wear and tear.

- Q: How is steel wire rod used in the manufacturing of wire for automotive exhaust systems?

- Steel wire rod is a crucial component in the manufacturing process of wire for automotive exhaust systems. It serves as the raw material for the production of high-quality wire used in these systems. To begin with, steel wire rod undergoes a series of processes to transform it into wire suitable for automotive exhaust systems. The rod is first heated and then passed through a series of rolling mills to reduce its diameter and increase its length. This process, known as hot rolling, ensures that the wire rod achieves the desired dimensions and mechanical properties. Once the wire rod has been rolled to the desired size, it is then subjected to further processing. This may include surface treatment, such as pickling or coating, to enhance its corrosion resistance and durability. Additionally, the wire may undergo specialized heat treatments, such as annealing or quenching, to improve its strength and flexibility. After these treatments, the wire is ready to be used in the manufacturing of automotive exhaust systems. It is typically formed into intricate shapes and configurations to fit specific exhaust components, such as catalytic converters, mufflers, or exhaust pipes. The wire is carefully bent, coiled, or woven to achieve the desired shape and ensure a secure fit within the exhaust system. The wire plays a critical role in the overall performance of automotive exhaust systems. It is used for various purposes, including providing structural support, reducing vibration and noise, and facilitating the flow of exhaust gases. The durability and strength provided by steel wire rod ensure that the wire can withstand the harsh conditions of the exhaust system, including high temperatures, corrosive gases, and mechanical stresses. In summary, steel wire rod is an essential material used in the manufacturing of wire for automotive exhaust systems. Through a series of processing steps, the wire rod is transformed into high-quality wire that is used to create intricate shapes and configurations for exhaust components. The strength, durability, and corrosion resistance of the wire ensure optimal performance of the exhaust system, contributing to the overall efficiency and longevity of the vehicle.

- Q: How is steel wire rod used in the production of wire mesh for agricultural fencing?

- Steel wire rod is an essential raw material in the production of wire mesh for agricultural fencing. It is first drawn into a thinner wire, which is then woven or welded together to create the mesh pattern. This steel wire rod provides the strength and durability necessary for the fencing to withstand the elements and protect agricultural areas.

- Q: What is the typical diameter range of steel wire rod?

- The typical diameter range of steel wire rod can vary depending on the specific application and industry. However, in general, steel wire rods typically have a diameter ranging from 5.5mm to 20mm. The specific diameter chosen for a particular wire rod is determined by factors such as the intended use, strength requirements, and manufacturing processes. Different industries, such as construction, automotive, and electrical, may have their own specific diameter requirements for steel wire rods to meet the desired properties and performance standards of their products.

Send your message to us

Stainless Steel Sheet with Best Quality in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 45555555 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords