Stainless Steel Sheet SS305 with Best Quality in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 45555555 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of stainless steel plate:

stanless steel sheet roll

Manufacturer since 2003;

Origin from Baosteel & Tisco;

100% Manufacture's direct deal.

Festures of stainless steel plate:

| Packaging Details: | standard packing to export 4 eye bands and 3 circumferential bands in steel, galvanized metal fluted rings on inner and outer edges, galvanized metal & waterproof paper wall protection disk, galvanized metal & waterproof paper around circumference |

| Delivery Detail: | 15-25 days after received your deposit or to your quantity |

Specifications of stainless steel plate:

Product Name | cr 1219x2438 stanless steel sheet 201 |

standared | JIS, AISI, ASTM, GB, DIN,SUS |

Thickness | 0.2mm~2.5mm |

Size | 1000*2000mm,1219*2438mm or as per customers' request |

Surface finish | 2B, BA, Hair Line, No.1,No.4, Mirror Finish |

Application | Kitchenware, decoration construction and building ornament, product parts manufacturing and stainless steel products tooling and so on |

Payment terms | T/T 30% for deposit, Balance against the copy of B/L; or L/C at sight |

Product Packing | wooden pallet |

Delivery time | within 15-20 working days after we got your 30% deposit |

Attention | FREE SAMPLES can be sent on request. |

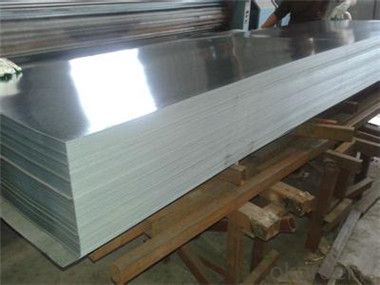

Images of stainless steel plate:

FAQ:

1. What is your package?

Packing situation: standard seaworthy packing or as customer required.

2. How long is the lead time?

Delivery time: 45 days after order confirmed.

3. What payment term do you accept?

Payment: T/T or L/C at sight.

- Q: What are the common mechanical properties of steel wire rod?

- The common mechanical properties of steel wire rod include high tensile strength, good ductility, excellent toughness, and high resistance to fatigue.

- Q: How are steel wire rods used in the manufacturing of mesh screens for filtration and separation?

- Steel wire rods are used in the manufacturing of mesh screens for filtration and separation by being woven together to form a strong and durable mesh structure. These rods provide the necessary strength and rigidity to support the mesh and ensure it can withstand the pressure and demands of the filtration and separation processes.

- Q: How is the steel wire rod market affected by changes in trade policies?

- The steel wire rod market can be significantly affected by changes in trade policies. Tariffs or quotas, for example, have the power to influence supply and demand dynamics, production costs, and the competitiveness of steel wire rod producers. When tariffs are imposed on steel wire rod imports, it becomes more expensive for domestic manufacturers to source raw materials, as the cost of importing the product increases. Consequently, the price of steel wire rod in the domestic market may rise, impacting the profitability of manufacturers and potentially reducing demand. Conversely, if tariffs are placed on steel wire rod exports, it limits the market access for domestic manufacturers, which in turn reduces their ability to sell their products internationally and potentially affects their revenue. Quotas on steel wire rod imports can also have a significant impact on the market. By limiting the quantity of imported steel wire rod that can enter the domestic market, quotas can cause a decrease in supply, potentially resulting in a shortage and driving up prices. Similarly, if quotas are imposed on steel wire rod exports, it may restrict the ability of domestic manufacturers to access international markets, thus reducing their market reach and potentially affecting their profitability. Furthermore, trade policies can impact the competitiveness of domestic steel wire rod producers. If trade policies favor domestic producers by imposing higher tariffs on imports, it provides them with a competitive advantage by making imported steel wire rod more expensive. This, in turn, can encourage domestic production and potentially lead to increased investment in the industry. Conversely, if trade policies favor imports by imposing higher tariffs on exports, it can hinder the competitiveness of domestic producers, making it challenging for them to compete in international markets. In conclusion, changes in trade policies can have both positive and negative impacts on the steel wire rod market. The extent of these impacts depends on the specific trade policies implemented and the reactions of market participants.

- Q: What are the major trade associations and organizations in the steel wire rod industry?

- The steel wire rod industry comprises numerous significant trade associations and organizations. Among them are the following prominent ones: 1. American Wire Producers Association (AWPA): AWPA serves as a trade association that represents manufacturers of steel wire and wire products in North America. Its primary focus lies in promoting the industry's interests, offering technical expertise, and facilitating networking opportunities for its members. 2. International Wire & Machinery Association (IWMA): IWMA operates as a global trade association that brings together companies involved in wire and cable production and processing. It arranges industry events, provides market intelligence, and fosters collaboration and knowledge-sharing among its members. 3. Wire Association International (WAI): WAI functions as a non-profit organization dedicated to advancing, educating, and innovating the wire and cable industry. It offers educational resources, organizes technical conferences and exhibitions, and provides networking opportunities for professionals in the field. 4. European Steel Association (EUROFER): EUROFER represents the European steel industry, including manufacturers of wire rods. Its objective is to promote a competitive and sustainable steel industry in Europe. EUROFER advocates for its members' interests at the European Union level and offers industry-related information and services. 5. China Iron and Steel Association (CISA): CISA serves as a national trade association that represents the Chinese iron and steel industry, including wire rod producers. It plays a crucial role in policy advocacy, market research, and coordination among stakeholders in China's industry. These trade associations and organizations play a vital role in supporting the steel wire rod industry. They provide a platform for collaboration, knowledge-sharing, and addressing common challenges. Furthermore, they serve as valuable resources for industry professionals, offering technical expertise, market information, and networking opportunities.

- Q: What are the main factors influencing the choice of steel wire rod order storage tracking options?

- There are several main factors that influence the choice of steel wire rod order storage tracking options. Firstly, the size and complexity of the storage facility play a significant role in determining the tracking options. If the facility is large and has multiple storage areas or racks, it becomes essential to have a comprehensive tracking system that can accurately locate and monitor each order of steel wire rod. Secondly, the frequency and volume of incoming and outgoing orders also impact the choice of tracking options. If the facility handles a high volume of orders on a regular basis, a real-time tracking system that provides instant updates on the status and location of each order becomes crucial for efficient operations. Thirdly, the level of automation in the storage facility is another factor to consider. If the facility is highly automated, with robotic systems handling the movement and storage of steel wire rod, the tracking options should integrate seamlessly with the automation system to ensure accurate and synchronized tracking of orders. Additionally, the specific requirements and preferences of the customers and suppliers can influence the choice of tracking options. Some customers may require real-time updates and visibility into the status of their orders, while others may prioritize cost-effectiveness or simplicity. Similarly, suppliers may have their own tracking systems in place, which need to be compatible with the storage facility's tracking options. Lastly, the overall budget allocated for implementing and maintaining the tracking system is an important consideration. More advanced tracking options, such as RFID or barcode systems, may require higher upfront investment and ongoing maintenance costs. Therefore, the financial resources available will impact the chosen tracking options. In conclusion, the choice of steel wire rod order storage tracking options is influenced by factors such as the size and complexity of the storage facility, the frequency and volume of orders, the level of automation, customer and supplier requirements, and budget constraints. By carefully considering these factors, an appropriate tracking system can be selected to streamline operations and enhance efficiency in managing steel wire rod orders.

- Q: What are the different inclusion testing methods for steel wire rod?

- Steel wire rod commonly undergoes several different inclusion testing methods to detect and analyze non-metallic impurities that can affect its quality and performance. One method frequently used is microscopic examination. This involves taking a sample of the wire rod and preparing it for examination under a microscope. The sample is typically polished and etched to enhance visibility. By observing the size, shape, and distribution of the inclusions, they can be identified and characterized. Another widely employed inclusion testing method is ultrasonic testing. This technique employs high-frequency sound waves to detect and analyze inclusions in the wire rod. The waves pass through the material, and any disturbances caused by inclusions are detected and analyzed. This method provides information about the size, location, and type of inclusions present. In addition to these methods, more advanced techniques are available for inclusion testing. These include scanning electron microscopy (SEM), energy-dispersive X-ray spectroscopy (EDS), and X-ray diffraction (XRD). SEM allows for highly detailed imaging of inclusions, while EDS provides elemental analysis. XRD is used to determine the crystallographic structure of the inclusions. The choice of inclusion testing method depends on several factors, such as required accuracy, the specific type of inclusions of interest, and available equipment and expertise. Each method has its own advantages and limitations, so it is often advantageous to use a combination of techniques to gain a comprehensive understanding of the inclusions in steel wire rod.

- Q: How are steel wire rods used in the manufacturing of bicycle spokes for strength and flexibility?

- The manufacturing process of bicycle spokes relies heavily on steel wire rods, which are crucial for providing both strength and flexibility. These rods are essential as they enable optimal performance by withstanding the various forces and stresses encountered during cycling, such as the rider's weight and impacts from uneven surfaces. The strength of steel wire rods holds immense importance in bicycle spokes, as they need to support the rider's weight and transfer the force generated from pedaling to the wheels. Steel is renowned for its high tensile strength, making it capable of resisting significant pulling or stretching forces without breaking. This characteristic makes it an ideal material for bicycle spokes that must sustain the rider's weight and maintain stability. Additionally, steel wire rods offer exceptional flexibility, allowing the spokes to efficiently absorb and distribute external forces. This flexibility plays a significant role in shock absorption and vibration reduction, thus minimizing the impact on the overall structure of the bicycle and enhancing the rider's comfort. Manufacturers typically shape the steel wire rods into specific profiles to optimize both strength and flexibility. Often, these rods undergo a cold-drawing process, which further enhances their tensile strength while preserving their flexibility. As a result, cold-drawn steel wire rods possess the necessary strength to withstand the forces experienced during cycling, yet they retain enough flexibility to enable the spokes to adapt and accommodate different road conditions. In conclusion, the utilization of steel wire rods is indispensably crucial in bicycle spoke manufacturing due to their integral role in providing strength and flexibility. With their high tensile strength, these rods ensure the spokes can effectively bear the rider's weight and transfer forces, while their flexibility aids in shock absorption and vibration reduction. Ultimately, steel wire rods are vital components that guarantee the durability and performance required for spokes in bicycle manufacturing.

- Q: How is steel wire rod used in the production of wire for musical instruments?

- Steel wire rod is used in the production of wire for musical instruments as it provides the necessary strength and durability required for the strings. Through a series of processes such as drawing, annealing, and coating, the steel wire rod is transformed into thin and flexible wire that can be used for guitar, piano, or violin strings. The quality of the steel wire rod directly affects the sound quality and longevity of the instrument's strings, making it an essential component in their production.

- Q: What are the common applications of pre-stressed and oil tempered steel wire rod?

- Pre-stressed steel wire rod is commonly used in construction and engineering applications, such as for pre-tensioning or post-tensioning of concrete structures, bridges, and high-rise buildings. It helps to improve the load-bearing capacity, durability, and overall structural integrity of these projects. On the other hand, oil tempered steel wire rod is frequently utilized in the manufacturing of springs, suspension systems, and other high-stress applications. Its unique properties, obtained through the tempering process, provide excellent resistance to fatigue and ensure reliable performance in demanding industries such as automotive, aerospace, and machinery.

- Q: How is steel wire rod used in the production of wire mesh for animal enclosures?

- Steel wire rod is an essential element in manufacturing wire mesh for animal enclosures, as it serves as the primary material from which the wire mesh is formed. The wire rod, typically composed of low carbon steel, undergoes a series of processes to achieve the desired wire mesh. To begin, the steel wire rod is drawn through a set of dies to reduce its diameter and increase its length. This wire drawing process ensures that the wire rod possesses the appropriate thickness and strength required for its intended use in animal enclosures. Once the wire has been drawn, it is often galvanized to enhance its durability and resistance to corrosion. Galvanization entails immersing the wire in molten zinc, resulting in a protective zinc coating that effectively prevents rust and prolongs the lifespan of the wire mesh. Subsequently, the galvanized wire is either woven or welded together to form the wire mesh structure. Woven wire mesh is created by interlocking the wires in a crisscross pattern, resulting in a robust and flexible mesh. Conversely, welded wire mesh is fashioned by joining the wires together at their intersections, yielding a more rigid and stable mesh. The wire mesh produced from steel wire rod offers several benefits for animal enclosures. Its strength and durability enable it to withstand the impact and pressure exerted by animals, ensuring their safe containment. Additionally, the small gaps between the wires provide ventilation and visibility, allowing animals to see their surroundings while maintaining a secure enclosure. In conclusion, steel wire rod plays a crucial role in the production of wire mesh for animal enclosures, providing the necessary strength, durability, and security to create a safe and reliable enclosure for various types of animals.

Send your message to us

Stainless Steel Sheet SS305 with Best Quality in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 45555555 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords