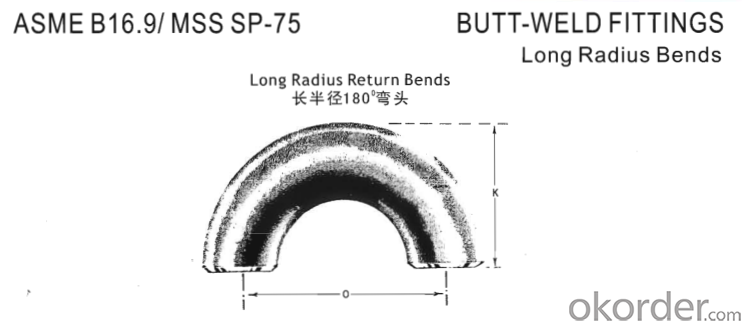

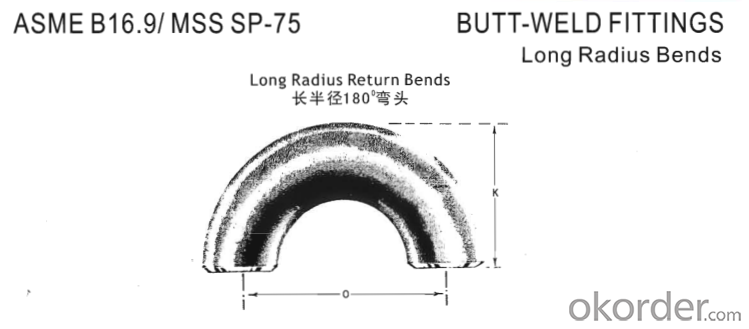

Alloy Steel Pipe Fittings Butt-Welding 180° Long Radius Bends

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features standards and products of our butt welding fittings:

Features of butt welding fittings:

1. High class materials

Our products only use high class raw materials of carbon/alloy steel pipes made from NKK or MANNESSMANN equipment for ordinary, high pressure, low/high temperature,boiler and other purposes.

2. Uniform wall thickness and perfectly round

This can be achieved by our particular technical knowhow and our quality control program.

3. Accurate dimension

Efficient piping work can be made only with fittings of correct dimensions and shapes. Our fittings are finished to have accurate straight/ plane ends, beveled angle...etc. to applicable standards by means of two or three spindle beveling machines.

Standards of butt welding fittings:

Our welding fittings are manufactured in compliance with the following appliance standards:

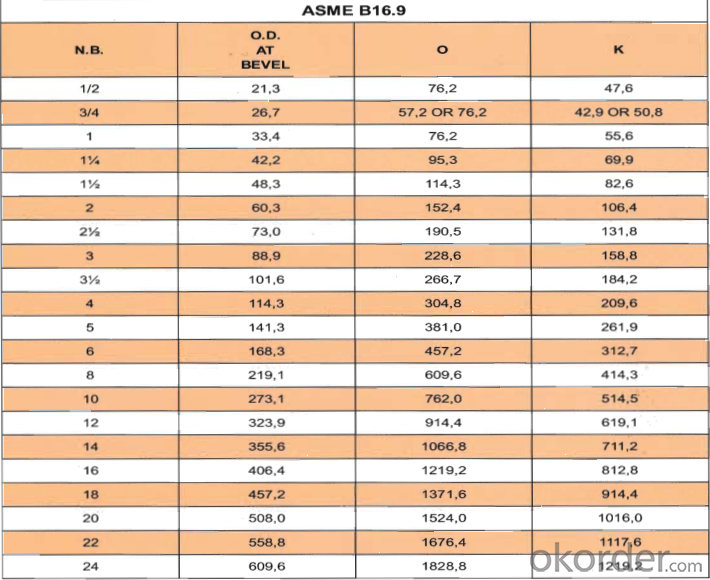

ASME B16.9 ASTM A234 MSS-SP43 WPHY60 JIS B2311 DIN2605

ASTM A403 MSS-SP75 WPHY65 JIS B2312 DIN2606

ASTM A420 WPHY42 WPHY70 JIS B2313 DIN2616

ASTM A860 WPHY52 DIN2615

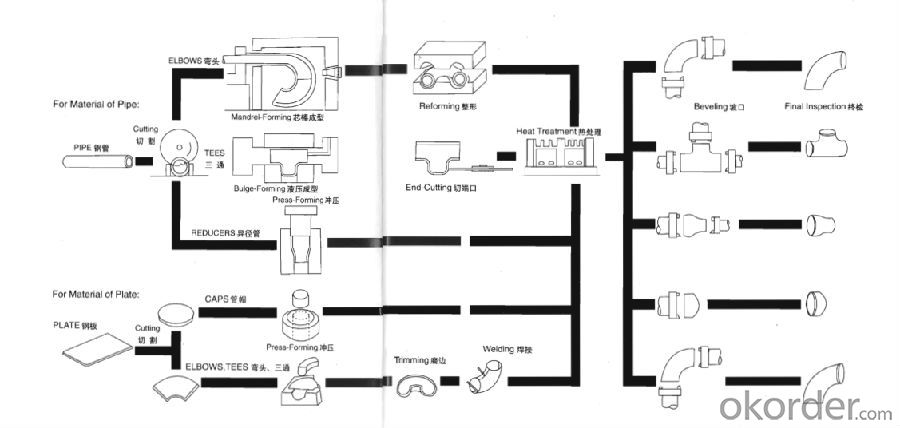

Manufacturing method and process:

BUTT-WELD FITTINGS ASME B16.9/MSS SP-75

180° Long radius bends:

Packing of butt welding fittings:

FAQ of butt-welding fittings:

1) Q: What’s your main product? Which kinds of products are more competitive in your product range?

A: Our main products are steel flanges, pipe fittings and steel pipes.

Competitive Items: flanges in stainless steel, carbon steel, alloy steel and punching carbon steel

Butt welded pipe fittings in stainless and carbon steel

2) Q: what’s your largest size of flange and fitting? How long is the production cycle?

A: The largest flange we could produce is 80’’ and the largest fitting is 50’’.

In general, we spend 20-25 days in a 20-ton order. If necessary, we could make it shorter.

3) Q: Could you produce according to the drawings?

A: Sure. We could produce according to the provided drawings, which include forged and casted items.

4) Q: What kind of certificates do you have?

A: We have ISO, TUV, API,SGS,BV etc. fittings in stainless and carbon stee

Malleable Iron ,Stainless and carbon steel pipes

- Q: Can flared and jacketed hydraulic couplings be used as gas line couplings?

- Yes, but it's not economical.Hydraulic pipe joint pressure is very high, commonly used in 16MPa, 25MPa, 35MPa several levels.

- Q: i have fibromialga (sp) and it really helps if i sleep with one but im anxious that its not the best choice.. please help :)

- Well don't expect to walk on the field after a week of practice and be the best one. I have been playing for 8 years, I'm a freshman in high school, I'm 14. I play varsity JV. We have practice everyday for 2+ hours wheather its raining, cold, hot, sleeting, etc., and sometimes on the weekend. I don't have much free time, so if your gonna play for your school or city large then get ready for nonstop pratice. Most people say soccer is that you just run up and down the field and it takes a long time to score. well its not, its more to it when your a player. Its a very contact sport so you may get winded or knocked out but youve gotta get back up to the ball. you need to know how to dribble, run endurance, run for speed, head the ball, chest the ball, kicking when your pressured, defending, shooting, juggling, corner kicks, pks, throw ins. etc etc. You need to know the rules and all the postions. It takes a lot of skills, if you feel like its too much, ask one of the girls to do some one on one with you on the weekend then try out next year. If you put your heart into something, anything is possible.

- Q: Or are you lobbying for a fire breathing dragon park in your neighborhood like I am?Since Winkie is just a baby I've been slapped with 4 law suits because all he wants to do is play with the dogs he doesn't mean to scorch them.

- Most High pressure compressed gas tanks are of seamless construction (forged from one piece of metal), of high quality materials, produced under carefully controlled conditions and fully tested. Most common pipe has a welded seam, and if you screwed on the caps, that would mean you are using threaded pipe and cutting the threads reduces the strength. High quality seamless pipe with suitable welded fittings could potentially have a working pressure in the thousands of PSI, but that is different than what you seem to be asking about.

- Q: POLL: Is there a fire extinguisher in your home? BQ: Do you know how to use it?

- I think 14 is Frame 25 is either pixel or mega pixel i cant remember which is smaller 26 is a telephoto lens 40 is flash down 4 diffuseri think that is how it is spelled

- Q: Im doing this for a school project.. So if you could please answer this I need your opinions!

- I asked the stylist a good shampoo Conditioner last time I got my hair cut and she suggested Tresemme I have been using it now for like 7 months straight and have noticed a big change.

- Q: so i'm an incredibly heavy sleeper, but i'm planning on going to a residential high school after this school year and i'd have to wake up to an alarm clock, does anyone have any suggestions on how to make that easier?

- Make sure you get the pipe fittings glued on well, especially if this is a crawlspace or somesuch where you might not detect a new leak quickly. Next time you cut the pipe, glue in a clean-out fitting. You would still need to own, rent or borrow a snake, but having clean-outs every 50 or 100 ft will make that a lot easier.

- Q: what industries commonly use control system?

- AS LONG AS YOU HAVE ONE CAT ON THE TRUCK UR EMISSIONS SHOULDN'T CHANGE TO A DEGREE WHERE YOU'LL FAIL INPECTION. AND 9 OUT OF 10 TIMES, ITS NOT A DOUBLE CAT SYSTEM, ONE IS THE CAT AND THE OTHER IS A RESONATOR. I DID THE SAME THING TO MY FULL SIZE BRONCO AND ITS FINE. JUST MAKE SURE ALL THE PIPES AND FITTINGS R TIGHT OR U'LL GET AN EXHAUST LEAK

- Q: Can the medium and high pressure system fail to use the raw meal belt, and can the raw meal belt be corroded into the oil circuit by the oil corrosion?What kind of sealant do you use? Recommend it

- It is best not to use, with American conical teeth hard seal, NPTF generally very few people with this. High precision ah!

- Q: I've got an 6 speed, 2 wheel drive, 2008 Jeep Sahara Unlimited and I need snow chains or cables for my tires. My tires are 255/70/18 and need best to know what works awesome for Icy/snow roads?

- Its not easily done. The fittings allow a lap joint which is then soldered making a very strong and robust joint. What you are proposing would create a butt joint and they are very weak. There are some types of rubber boots that might allow this to be done but I've not seen anything exactly like what you are requesting.

- Q: OK I was 12 when I started wetting the bed.I just wasent once or twice it was everyday.I started wearing a diaper.I would fill it up then it would leak out .To make it worse my mom would make my sister go to the store to get daipers .She always bought boy super hero or transformer.Then should would take me to the store just to pull down my pANTS.I got rubber sheets.but it still leaked out.One time i went camping with a friend .i leaked all in the tent.I was still sleeping so my friend took a picture of me with my front wet, and my diaper completely fullCAN YOU TELL ME YOUR STORY OR SOMTHING THAT COULD HELP IM 14 WETTING THE BED HELP AM I WIERD OR A LOOSER

- What you will need is plenty of 4, 3, 2, 11/2 schedule 40 DWV PVC pipe. Plenty of fittings, and a 4 twin clean-out. A couple of quart cans of primer glue, a trencher, a tape measure, hammer a few long stakes, a torpedo level..and a good saw. You will also need a couple rolls of 3/4 type L soft copper, and depending on the size house, 2 to 3 rolls 1/2 type L soft copper. The copper fittings to make a distribution manifold at the water heater. An acetylene B tank torch, some sand cloth, tinning flux and a roll of lead-free solder. You have to know how to read the plans in order to get any water lines that are in the center of the wall it stubs up into, as well as where to rough-in the main trunk drain line, its branches and vent stacks for easy drainage. You have to know how to weld without wasting solder and clogging the pipe. You will have to know what to do after the frame of the house is put up and the second stage entails; stubbing up out and running stack-out. When the house is almost finished, its time for fixtures. AND you have to do it all following your state/county/city plumbing codes for what size pipe can run what and get a permit inspection. You cannot move ahead to the next stage without a green tag. Think you can handle it? It takes some apprentices at least two years of the three required before he can take the license test to get a clear vision of how to not waste materials and still design a system that works without fail for decades and decades. So, to answer your query: Yes, its hard.

Send your message to us

Alloy Steel Pipe Fittings Butt-Welding 180° Long Radius Bends

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords