Stainless Steel Marble Bracket/Accessories

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 Pieces pc

- Supply Capability:

- 1000000 Pieces Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

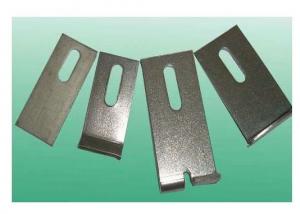

Type: Stainless steel marble bracket

Place of Origin: Jiangsu China (Mainland)

Model Number: ST-G01

Introduction:

The non-rust of the stainless steel means it can have certain chemical stability around the corrosion mediums of air, water, acid, alkali, salt or others. But it does not mean the stainless steel will never rust. Whether the stainless steel will rust or not is influenced by the molecular structures, the processing technic, and the operating environment and so on. To prevent the stainless steel from rusting extremely, please pay attention to the followings:

1. Stone fixation, stainless steel/Inox

2. Z Restraint/Support bracket/anchor

3. Brackets can be adjustable in 3 directions

1 |

Product Name |

Stainless steel marble bracket/accessories |

2 |

Brand |

|

3 |

Model |

ST-G01 |

4 |

Size |

According to customers' requirements |

5 |

Material |

201, 302, 304, 304L, 316, 316L, according to customers' requirements |

6 |

Standard |

GB, JIS, AISI, BS, DIN |

8 |

Finishing |

Cold draw hairline and Fluorocarbon coating(all kinds of colors) |

9 |

Usage |

stainless steel angle to fix marble stone one the wall |

10 |

Package |

Bubble bag + Inner box + Carton |

11 |

MOQ |

5000 pieces |

12 |

Delivery time |

15-30 days after receiving the full payment |

13 |

Price |

0-100 USD/piece |

14 |

Service | 1.Product design drawings (CAD) |

| 2.Professional engineer advices | ||

| 3.Installation guiding | ||

| 4.Product Warranty is offered | ||

| 5.OEM, ODM , Customer design | ||

15 |

Payment |

L/C, T/T |

16 |

Ability |

1000,000 pieces/month |

Suggestion:

1. Recommended projection size between 45 mm to 135 mm and loads up to 800N.

2. In horizontal joint installation slabs are pinned on the bottom and upper sides. Anchors act as load bearing carrying half the weight of the slabs above. Anchors also act as restraint holding the slabs below and restraining against wind suction and pressure.

3. In vertical joints installation slabs are pinned at the left and right sides. Anchors on the bottom are load-bearing anchors carrying the whole weight of the slab. Half the slab is on the left and half the slab is on the right. Anchors on the top are restraint anchors holding the slabs and restraining against wind suction and pressure.

4. Three - dimensional adjustability allows quick and easy installation.

After many years, we can:

Own design - meet the project needs;

Own production - ensure that the project in a timely manner;

Rigorous testing - ensure good quality;

Dedication to service - ensure customer's satisfaction;

The whole management - ensure Honor.

- Q: What is the difference between the price of the pick up claw?

- Material 201,304,316, from time to good, the most commonly used is 304. The larger the size, of course, the price is smaller than the size of the expensive

- Q: What is the meaning of the radial curtain of the glass curtain wall?

- Uses: Splicing claws in the glass curtain wall played a role in the convergence of the joints through the load to the steel structure or other body structure, its mechanical properties in this is particularly important. Performance Description: The use of splicing claws to connect the glass curtain wall transparent appearance, because no walls, good lighting, indoor space and outdoor environment can be integrated. Split claws support structure and diverse, to meet the needs of different building structures and decorative effects. Part of the split jaw pieces with spherical hinge connection, with the ability to absorb deformation, safety is also a great guarantee

- Q: The installation method of the splicing jaws

- Splicing claw installation method is not difficult, a few things on the assembly under OK.

- Q: What are the fittings of the stainless steel splicing jaws used on the glass curtain wall?

- There are smelting furnace, that is, you can customize the meaning of non-standard parts, this is not much, only individual home, the furnace like this

- Q: Glass curtain wall glass installation process requirements which out

- The first is the preparation before the installation. Stainless steel splicing jaws Before installing, check whether the mounting position of the splicing jaws is accurate. Proof of the steel structure of the main support of the vertical, elevation, beam height and level of compliance with the design requirements, with particular attention to the installation of holes in the review. And then clean the stainless steel and sucker, according to the weight of stainless steel and sucker to determine the number of suction cups. And use the steel brush to clean the surface of the steel tank and the bottom of the groove, the bottom of the stainless steel stainless steel U-shaped steel groove should be added chloroprene rubber pad from the edge of the stainless steel 1/4 width. Field installation of stainless steel splicing claws need to pay attention to the point is due to the specific size of the splicing system size can not be wrong, you must use the torque wrench to determine the torque, the purpose of doing so is to ensure that the joints at the air tightness and watertight Sex. Then install the splice and stainless steel on the mounting platform and install it with the splicing jaws. After the installation of the scene, to ensure that the level of stainless steel deviation within the allowable range, should pay attention to adjust the position up and down about. After all the adjustments are completed, the overall flatness of the facade should be checked to ensure correctness.

- Q: Splicing the claws of the claws

- The appearance of the glass curtain wall with the connection of the pawl is transparent, and the interior space and the outdoor environment are fused due to the lack of wall and good lighting. Split claws support structure and diverse, to meet the needs of different building structures and decorative effects.

- Q: Members of the master is good, I want to pull the claw side of the stainless steel support the side of the glass, one side installed in the antiseptic wood, please practice in the anti-wood that side how to install, how fixed on the wood preservative.

- Directly with expansion bolts fixed on the wood preservative. The splicing jaws are mainly used as support joints and transfer loads to a fixed support structure, which is an important accessory to the glass curtain wall.

- Q: What are the skeleton of the glass curtain wall system

- Pendant glass curtain wall This is the use of four-jaw stainless steel pendant with the column welding, pendant of each claw with a glass of a hole connected to the two pendant at the same time with four glass connected, or a piece of glass fixed on the four pendant. Four holes drill holes.

- Q: Can the splicing jaw be welded to the stainless steel tube?

- Split claws support structure and diverse, to meet the needs of different building structures and decorative effects. Part of the split jaw pieces with spherical hinge connection, with the ability to absorb deformation, in the security also has a great protection.

- Q: How many of the glass curtain wall are to be welded to the pillar

- Specific force situation Caixing, Rui Teng curtain wall is the industry well-known brands, you can ask their technical staff.

1. Manufacturer Overview

| Location | Zhejiang, China |

| Year Established | 2010 |

| Annual Output Value | US$1 Million - US$2.5 Million |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe South Asia Domestic Market |

| Company Certifications | ISO 9001:2000 ISO 9001:2008 CELAB |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | NINGBO,SHANGHAI |

| Export Percentage | 51% - 60% |

| No.of Employees in Trade Department | 3-5 People |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 3,000-5,000 square meters |

| No. of Production Lines | 8 |

| Contract Manufacturing | OEM Service Offered Design Service Offered |

| Product Price Range | Low and/or Average |

Send your message to us

Stainless Steel Marble Bracket/Accessories

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 Pieces pc

- Supply Capability:

- 1000000 Pieces Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches