Stainless Steel Coil Cold Rolled 304 AISI With Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Coil Cold Rolled 304 With Good Quality

1.Structure of Stainless Steel Coil Cold Rolled 304 With Good Quality

Cold Rolled stainless steel Coil with good quality is one of the raw material of the cold rolled stainless steel Coil, which can be used directly in many places. Stainless Steel (Stainless Steel) is short for acid-proof Stainless Steel, resistant to weak corrosive medium such as air, steam, water, or with a Stainless Steel grade.

2.Main Features of Prefabricated Steel Structure High Building Project

Weldability: The purpose of the different requirement for welding performance are different.1 Kind of tableware generally do not require the performance of welding, even including some pot class enterprise. But the vast majority of products all need raw materials welding performance is good, like the 2 kinds of tableware, thermos flask, steel pipes, water heaters, water dispensers, etc.

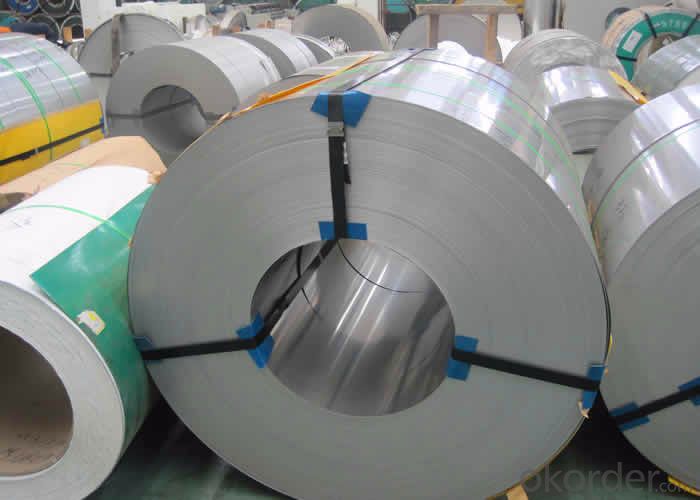

3. Stainless Steel Coil Cold Rolled 304 With Good Quality Images

4. Stainless Steel Coil Cold Rolled 304 With Good Quality Specification

The word "stainless steel" is not merely refers to a pure stainless steel, but said more than one hundred kinds of stainless steel industry, the development of each stainless steel has good performance in their specific applications. The key to the success of the first is to make clear purpose, and then determine the correct material. Related to architectural construction applications usually only six types of steel. They contain 17 ~ 22% chromium, good steel contains nickel. Add molybdenum can further improve the atmospheric corrosion resistance, especially containing chloride atmospheric corrosion resistance. Stainless steel often according to the state of organization can be divided into: martensite steel, ferritic steel, austenitic steel, austenitic (two-phase) - ferrite stainless steel and precipitation hardening stainless steel, etc. In addition, according to ingredients can be divided into: chromium stainless steel, chromium nickel stainless steel and chromium manganese nitrogen stainless steel, etc.

5. Applications of Stainless Steel Coil 304 With Good Quality

1. Kitchenware: tableware, cookware, Stoves…

2. Food packing: storage cans, food containers…

3. Construction: bridge, roofing, wall, decoration, bathroom accessories…

4. Precision instruments: electrical products, aerospace…

5. Others: automotive parts, machine building, chemical processing, farming…

6.FAQ of Stainless Steel Coil 304 With Good Quality

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How is the packaging and delivery?

Standard export packing (Coil: waterproof paper + protective steel ring; Circle: wooden box), or as your requirement and the delivery term is based on the project.

④How long can we receive the product after purchase?

In the purchase of product within 20 working days, We will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 20 to 40 working days can be served.

- Q: How do you prevent discoloration of stainless steel strips?

- To prevent discoloration of stainless steel strips, there are several steps you can take: 1. Regular cleaning: Stainless steel should be cleaned regularly to remove any dirt, grime, or other contaminants that can lead to discoloration. Use a mild detergent or stainless steel cleaner and a soft cloth or sponge to clean the strips. Avoid using abrasive materials or harsh chemicals that can scratch or damage the surface. 2. Proper drying: After cleaning, make sure to thoroughly dry the stainless steel strips to prevent water spots or mineral deposits from forming. Use a clean, lint-free cloth to dry the surface, ensuring no moisture remains. 3. Avoid exposure to harsh chemicals: Stainless steel is resistant to many chemicals, but prolonged exposure to certain substances can cause discoloration. Avoid contact with bleach, chlorides, acids, and other corrosive chemicals as much as possible. If accidental exposure occurs, rinse the strips immediately with clean water and dry thoroughly. 4. Protective coating: Applying a protective coating or finish can help prevent discoloration and enhance the appearance of stainless steel strips. There are various types of coatings available, such as clear lacquer, polyurethane, or wax. Follow the manufacturer's instructions for application and reapplication as needed. 5. Avoid high temperatures: Excessive heat can cause stainless steel to discolor or even warp. Avoid placing hot pans, pots, or other objects directly on the stainless steel strips. Use trivets, pot holders, or heat-resistant mats to protect the surface. 6. Regular maintenance: In addition to regular cleaning, periodic maintenance can help prevent discoloration. Inspect the strips for any signs of damage or corrosion, and address any issues promptly. If discoloration does occur, there are stainless steel cleaners and polishes available that can help restore the original appearance. By following these preventive measures and maintaining proper care, you can significantly reduce the risk of discoloration and keep your stainless steel strips looking clean and vibrant for longer periods.

- Q: How do stainless steel strips perform in cryogenic environments?

- Stainless steel strips perform well in cryogenic environments as they exhibit excellent resistance to low temperatures, maintaining their strength, toughness, and corrosion resistance.

- Q: Can stainless steel strips be used for architectural canopies?

- Yes, stainless steel strips can be used for architectural canopies. Stainless steel is known for its durability, strength, and resistance to corrosion, making it a popular choice for architectural applications. The strips can be shaped and fabricated to create unique and visually appealing canopies that offer protection from the elements while maintaining a sleek and modern aesthetic.

- Q: How do stainless steel strips perform in the presence of alkalis?

- Stainless steel strips generally have good resistance to alkalis, making them suitable for various applications where they may come in contact with alkalis without experiencing significant corrosion or degradation.

- Q: Can stainless steel strips be used in the production of automotive body panels?

- Yes, stainless steel strips can be used in the production of automotive body panels. Stainless steel is known for its durability, corrosion resistance, and aesthetic appeal, making it a suitable material for automotive applications. It provides strength and protection against rust, making it a popular choice for body panels that need to withstand harsh weather conditions and potential impacts.

- Q: Can stainless steel strips be used in the pharmaceutical industry?

- Yes, stainless steel strips can be used in the pharmaceutical industry. Stainless steel is a popular material choice due to its high corrosion resistance, durability, and ability to withstand high temperatures and harsh chemicals. It is commonly used for manufacturing pharmaceutical equipment, storage tanks, and process piping to maintain hygienic conditions and prevent contamination in pharmaceutical processes.

- Q: Can stainless steel strips be used in medical instrument manufacturing?

- Indeed, the utilization of stainless steel strips is applicable in the manufacturing of medical instruments. The medical industry frequently opts for stainless steel as a material of choice due to its exceptional characteristics, such as its resistance to corrosion, formidable strength, and ability to withstand high temperatures. These properties render stainless steel strips highly suitable for an extensive array of medical instruments, encompassing surgical tools, dental implements, implantable devices, and diagnostic apparatuses. Moreover, stainless steel possesses the added advantage of being effortlessly cleaned and sterilized, a vital requirement in upholding a sterile environment within medical facilities. Consequently, stainless steel strips are extensively employed in the manufacturing of medical instruments owing to their robustness, dependability, and hygienic attributes.

- Q: What are the different types of stainless steel strip edges?

- Various applications commonly utilize different types of stainless steel strip edges. These options include: 1. Mill Edge: Generated during the hot rolling process, this standard edge features a slightly rounded shape and may contain some mill scale. 2. Slit Edge: Achieved by slicing the coil into narrower strips, this edge is characterized by a straight form, smooth surface, and absence of burrs. 3. Deburred Edge: Formed by eliminating any burrs or sharp edges from the slit edge, this type provides a smoother and safer finish. 4. Rounded Edge: By rounding the strip's sharp edges, this edge is frequently employed in safety-conscious industries like food production. 5. Beveled Edge: Created through the beveling of the strip at a specific angle, this edge finds application in scenarios requiring a tight fit or welding. The selection of a stainless steel strip edge depends on the specific application and desired outcome. Each edge type possesses unique advantages and may be suitable for varying purposes.

- Q: How do you prevent stress corrosion cracking of stainless steel strips?

- To prevent stress corrosion cracking of stainless steel strips, several measures can be taken: 1. Material selection: Choose the appropriate grade of stainless steel that resists stress corrosion cracking. Austenitic stainless steels, such as 304 and 316, are commonly used due to their high resistance to corrosion. 2. Avoid exposure to corrosive environments: Ensure that the stainless steel strips are not exposed to environments containing corrosive elements such as chlorides, acids, or alkalis. This can be achieved by proper storage and handling, as well as avoiding contact with chemicals that might cause corrosion. 3. Control stress levels: Stress corrosion cracking is more likely to occur when stainless steel is subjected to tensile stress. Minimize stress levels by avoiding excessive bending, forming, or welding of the strips. Proper design and manufacturing techniques, such as using appropriate radii for bends and reducing residual stresses, can help prevent stress corrosion cracking. 4. Surface protection: Apply a protective coating or passivation treatment to the stainless steel strips to create a barrier against corrosive agents. Passivation removes surface contaminants and forms a passive oxide layer, enhancing the material's resistance to corrosion. 5. Regular maintenance and inspection: Regularly inspect the stainless steel strips for signs of corrosion or cracking. This allows early detection and corrective actions to be taken, preventing further damage and ensuring the longevity of the material. By following these preventive measures, stress corrosion cracking can be effectively minimized, ensuring the durability and performance of stainless steel strips in various applications.

- Q: Can stainless steel strips be used for pressure vessels?

- Yes, stainless steel strips can be used for pressure vessels. Stainless steel is known for its high strength, corrosion resistance, and durability, making it suitable for various applications, including pressure vessels. It is commonly used in industries such as oil and gas, chemical processing, and food processing. Stainless steel strips are often used to fabricate pressure vessels due to their flexibility and ease of shaping into the desired form. Additionally, stainless steel has excellent mechanical properties, allowing it to withstand high pressures and temperature variations. However, it is important to consider the specific requirements and standards for pressure vessels in each application to ensure that the chosen stainless steel grade and strip thickness meet the necessary criteria.

Send your message to us

Stainless Steel Coil Cold Rolled 304 AISI With Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords