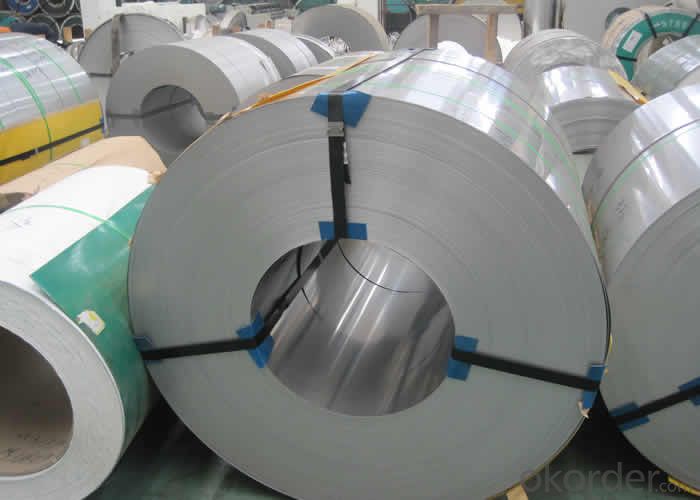

Hot Rolled Stainless Steel Coil 201 Narrow Strip No.1 Finish

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot Rolled Stainless Steel Coil 201 Narrow Strip No.1 Finish

Hot Rolled Stainless Steel 201 half copper Chemical Composition(%) |

| |||||||

C | Si | Mn | P | S | Ni | Cr | Cu |

|

0.1 | 0.5 | 10 | 0.04 | 0.01 | 1.20/1.30 | 13.00/14.00 | 0.8/1.0 |

|

Grade: | 200 Series | Standard: | JIS,AISI,ASTM,GB,DIN | Thickness: | 2.5/3.0/4.0mm |

Width: | 485/510/550/610/1010/1240mm | Place of Origin: | Shanghai China (Mainland) | Brand Name: | CNBM |

Model Number: | 201 | Technique: | Hot Rolled | Application: | Industrial tubes/kitchen/bath |

Certification: | ISO | THK: | 2.5/3.0/4.0mm | Face: | No.1 |

Usage: | tubes/kitchen/bath | Origin: | CHINA | ||

Packaging Detail: For customer's requirement

Delivery Detail:10-30days

201 Hot Rolled Stainless Steel Coil Specifications

THK:2.3/2.5/3.0/4.0mm

Width:485/510/550/610/1010/1240mm

Face:No.1

201 Hot rolled stainless steel Coil Application

Stainless steel is a production which not easy rust,acid resistance and corrosion resistance,so it is widely

used in light industry,heavy industry,daily necessities and the decoration industry.

201 hot rolled stainless steel coil, use to produce cold rolled stainless steel coil and stainless steel tube, pipe.

201 Hot Rolled Stainless Steel Coil

Strength Of Extension:100,000 To 180,000 Psi;

Yield Strength:50,000 To 150,000 Psi

Elongation :55 To 60%;

Modulus Of Elasticity:29,000,000 Psi;

Density :.280lbs/Cubic Inch(7.93g/Cm3)

- Q: Can stainless steel strips be used for architectural canopies?

- Architectural canopies can indeed utilize stainless steel strips. This material possesses exceptional durability and resistance to corrosion, rendering it ideal for outdoor purposes, including canopies. Its sleek and contemporary appearance enhances the elegance of architectural designs. Moreover, stainless steel strips can be effortlessly shaped and crafted into diverse dimensions, enabling the creation of personalized canopy designs. Furthermore, stainless steel's robustness and ability to withstand harsh weather conditions make it a dependable option for canopies that endure over time.

- Q: Are stainless steel strips suitable for high-temperature exhaust systems?

- Yes, stainless steel strips are suitable for high-temperature exhaust systems. Stainless steel is a corrosion-resistant and heat-resistant material that maintains its strength and integrity at high temperatures. It has excellent oxidation resistance, making it ideal for applications where the exhaust gases reach elevated temperatures. Stainless steel strips can withstand the extreme heat generated by exhaust systems, ensuring durability and reliability. Additionally, stainless steel's resistance to corrosion and rust allows it to withstand the harsh conditions and corrosive elements present in exhaust systems. Overall, stainless steel strips are a suitable choice for high-temperature exhaust systems due to their heat resistance, durability, and corrosion resistance properties.

- Q: What are the dimensions of stainless steel strips?

- The dimensions of stainless steel strips vary depending on their specific application and manufacturer. However, common dimensions for stainless steel strips range from 0.1 to 3.0mm in thickness and 10 to 600mm in width.

- Q: What are the factors affecting the strength of 111 stainless steel strips?

- The factors affecting the strength of 111 stainless steel strips include the composition of the steel, the manufacturing process, the temperature and time of heat treatment, the amount and distribution of impurities, the presence of strain hardening, and the thickness of the strips.

- Q: Can stainless steel strips be used in the electronics manufacturing industry?

- Yes, stainless steel strips can be used in the electronics manufacturing industry. They are commonly used for various applications such as shielding, grounding, and structural components in electronic devices. Stainless steel's corrosion resistance and high strength make it suitable for these purposes.

- Q: Are stainless steel strips suitable for brewery tanks?

- Indeed, brewery tanks find stainless steel strips to be incredibly suitable. Given its outstanding corrosion resistance, durability, and hygienic qualities, stainless steel remains a favored option for brewery equipment. By utilizing stainless steel strips, the tanks are safeguarded against rust, staining, and chemical reactions, rendering them exceptionally well-suited for beer storage and fermentation. Moreover, stainless steel's ease of cleaning is paramount in preserving the beer's quality and flavor. Consequently, incorporating stainless steel strips in brewery tanks emerges as a dependable and pragmatic decision for the brewing industry.

- Q: What is the corrosion resistance of stainless steel strips in saltwater?

- Stainless steel strips have excellent corrosion resistance in saltwater environments. The high chromium content in stainless steel forms a protective layer of chromium oxide on the surface, which acts as a barrier against corrosion and prevents the metal from reacting with saltwater. This makes stainless steel strips highly resistant to rust and corrosion caused by saltwater exposure. Additionally, stainless steel is also resistant to pitting corrosion, which is a common form of corrosion in saltwater environments. Therefore, stainless steel strips are widely used in marine applications, such as shipbuilding and offshore structures, where they are exposed to saltwater conditions.

- Q: Can stainless steel strips be heat resistant?

- Yes, stainless steel strips can be heat resistant. Stainless steel is known for its high resistance to heat and corrosion. Depending on the grade of stainless steel, it can withstand temperatures ranging from a few hundred degrees Celsius to over a thousand degrees Celsius. This makes stainless steel strips suitable for various applications where heat resistance is required, such as in automotive, aerospace, and industrial sectors. Additionally, stainless steel's heat resistance properties make it an ideal choice for cookware, oven components, and other household appliances that are exposed to high temperatures.

- Q: Can stainless steel strips be used in the production of aerospace components?

- Yes, stainless steel strips can be used in the production of aerospace components. Stainless steel offers excellent strength, corrosion resistance, and heat resistance properties, making it suitable for various aerospace applications. It is commonly used in the fabrication of aircraft structures, engine components, and other vital aerospace parts.

- Q: Can 111 stainless steel strips be used in nuclear power plants?

- Yes, 111 stainless steel strips can be used in nuclear power plants. Stainless steel is commonly used in nuclear power plants due to its excellent corrosion resistance, high strength, and ability to withstand high temperatures. The specific grade, 111 stainless steel, may be suitable depending on the specific application and requirements within the nuclear power plant.

Send your message to us

Hot Rolled Stainless Steel Coil 201 Narrow Strip No.1 Finish

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords