SR High Speed PVC Insulating Compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 3000 Tons kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

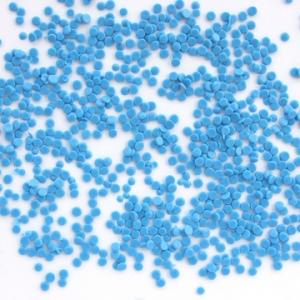

SR High Speed PVCInsulating Compound

I. Type andapplication

Type | Product | Application and Cable Specification |

2701N | 70℃ PVC insulating compound | PVC insulating compound for programmable exchanger wires. The extrude speed could be more than 1200m/min |

2801N | 80℃PVC insulating compound | PVC insulating compound for programmable exchanger wires. The extrude speed could be more than 1200m/min |

5801N-SR-1 | 80℃semi-hard PVC insulating compound | Applied to jumper wire of BT net 7000, 8000 and 9000 as insulation. |

5801N-SR | 80℃semi-hard PVC insulating compound | UL80℃semi-hard PVC as insulation. |

II. Productdescription

High speedPVC insulating compound for programmable exchanger wires, based onPVC resin, is made into granula by mixing, plastification and granulation withadding plasticizer, stabilizing agent, lubricant, modifying agent and etc.

III. Processing

It is recommended that compound should beprocessed with common extruder having a minimum L/D ratio of 20.

The following temperature(℃) profile of extruder is recommended:

Zone | Zone 1 | Zone 2 | Zone 3 | Zone 4 | Head | Die |

Temperature ℃ | 150 | 165 | 175 | 180 | 180 | 175 |

IV. Storageand transport

Packaging:25kg/bag,PE membrane inside bag and Kraft outside bag.

Storage and transport: Avoiding in directsunlight and weathering. The storage place should be in clean, cool, dry, andventilated conditions.

V. Properties

Table

Item | Unit | Standard Value | |||

2701N | 2801N | 5801N-SR-1 | 5801N-SR | ||

Tensile Strength | ≥ MPa | 18.0 | 18.0 | 30.0 | 24.0 |

Elongation at Break | ≥ % | 150 | 150 | 100 | 150 |

Impact Brittleness Temperature | ℃ | -15 | - | - | -10 |

Volume Resistivity, at 20℃ | ≥Ω﹒m | 1.0×1012 | 1.0×1012 | 1.0×1012 | 1.0×1011 |

Volume Resistivity, at 70℃ | ≥Ω﹒m | 1.0×109 | 1.0×1010 | - | - |

Dielectric Strength | ≥ MV/m | 22 | 22 | 20 | 20 |

Thermal Stability Time at 200℃ | ≥ min | 60 | 80 | 120 | 80 |

Hot Deformation | ≤ % | 40 | 40 | 40 | 40 |

Thermal Aging |

|

|

|

|

|

Aging Temperature | ℃ | 100±2 | 120±2 | 80±2 | 113±1 |

Aging Time | h | 168 | 168 | 168 | 168 |

Tensile Strength after aging | ≥ MPa | 18.0 | 18.0 | - | - |

Variation on Tensile Strength | % | ±20 | ±20 | ≥80 | ≥80 |

Elongation at Break after aging | ≥ % | 150 | 150 | - | - |

Variation on Elongation at Break | % | ±20 | ±20 | ≥80 | ≥75 |

Loss of Mass after aging | ≤ g/m2 | 20 | 20 | 10 | - |

- Q: How does an olive net help with harvesting olives?

- An olive net helps with harvesting olives by being placed under the olive tree to catch any fallen olives during the harvesting process. This prevents the olives from getting dirty or damaged by the ground, making it easier to collect and sort them later.

- Q: What is the difference between plastic PP1, PP2, PP3 and PP4?

- PP4 corrosive gases that contain acids, bases, and chemicals. PP5 high impact, toughening, weathering,.PP6, heat aging. PP6 applications: air conditioning systems. PP7 good chemical resistance, good liquidity, medium heat resistance, can be used in home appliances, automotive applications, industrial applications. PP8 high heat resistant. PP9 for automotive impeller and so on. PP10 high rigidity, high heat resistance, high gloss, high definition, used in food containers.

- Q: Can olive nets be used in regions with sandy or rocky soils?

- Yes, olive nets can be used in regions with sandy or rocky soils. These nets are primarily used to collect olives during harvest, regardless of the soil type. The nets are spread on the ground beneath the olive trees, catching the falling olives. The soil composition does not affect the functionality or efficiency of the nets in collecting the olives.

- Q: How do you know when it's the right time to install olive nets?

- The right time to install olive nets is typically determined by the maturity of the olives. It is recommended to install the nets when the olives have reached their desired ripeness and are ready for harvesting. Additionally, weather conditions and the presence of pests or birds in the orchard can also influence the decision to install olive nets.

- Q: How do olive nets impact the overall shelf life of the harvested olives?

- Olive nets can significantly impact the overall shelf life of harvested olives. By using these nets during the harvesting process, the olives are protected from falling on the ground and being exposed to soil, dust, and other contaminants. This helps to maintain the cleanliness and quality of the olives, ultimately extending their shelf life. Additionally, olive nets also prevent direct sunlight exposure, which can cause oxidation and deterioration of the fruit. Overall, using olive nets improves the longevity and freshness of the harvested olives, ensuring they can be stored and enjoyed for a longer period.

- Q: Can olive nets be used in different weather conditions?

- Yes, olive nets can be used in different weather conditions. They are designed to protect olive trees from birds and other pests, and are typically made of durable materials that can withstand various weather conditions such as rain, wind, and sun.

- Q: Can olive nets be used to reduce the risk of soil erosion in areas with poor soil conditions?

- Yes, olive nets can be used to reduce the risk of soil erosion in areas with poor soil conditions. Olive nets are designed to cover the soil surface, acting as a protective barrier against wind and water erosion. They help to stabilize the soil, prevent surface runoff, and promote water infiltration. Additionally, olive nets can also provide shade and retain moisture, which can improve the overall soil conditions and reduce erosion risks.

- Q: Do olive nets require any special maintenance during the off-season?

- Yes, olive nets require proper maintenance during the off-season. It is recommended to clean and store them properly to ensure their longevity. This can involve removing any debris or leaves trapped in the netting, gently washing them, and storing them in a dry place to prevent mold or damage. Additionally, regular inspection for any damages or wear is essential to address any issues before the next season.

- Q: Do all plastics have plasticizers?

- Plasticizer is divided into toxic and non-toxic, relieved, and now the plastic basically useless toxic plasticizers, and generally do not contain phthalate two formic acid

- Q: What sizes do olive nets come in?

- Olive nets come in various sizes, ranging from small sizes suitable for home gardens to larger sizes suitable for commercial olive groves.

Send your message to us

SR High Speed PVC Insulating Compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 3000 Tons kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords