High quality wire rod 6.5mm-14mm SAE1008 and 1006

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Product Description:

Specifications of Wire Rod SAE1008B:

Steel Grade: SAE1008B Standard: ASTM, GB

Diameter: 5.5mm, 6.5mm, 7mm,8mm,9mm,10mm,12mm,14mm

Type: Drawn Wire Alloy or Not: Alloy Brand Name: N-RIVER

Technique: Hot Rolled Place of Origin: China Mainland

Chemical Composition:

Please kindly find our chemistry of our material based on SAE1008B as below for your information

Grade | Chemical Composition (%) | |||||

C | Mn | S | P | Si | B | |

SAE1008B | 0.10max | 0.32max | 0.045max | 0.040max | 0.30max | 0.0008min |

Mechanical properties | ||||||

Yield strength(N/mm2) | Tensile strength(N/mm2) | Elongation (%) | ||||

≥195 | 350-380 | ≥32 | ||||

Usage and Applications of Wire Rod SAE1008B:

After hot-rolled the products shaped into coil and delivery as finished product, including round, square, rectangular, hexagonal and so on. Since most of the products are round, it is generally called wire rod. Carbon steel wire rod is widely used in construction and manufacturing. Carbon steel wire rod is mainly used for reinforcement of reinforced concrete and welded structure or reprocessed (roberts , nail, etc.) materials, especially used to produce wire drawing, welding electrode, nails, spring, electronic, precise machinery parts and so on.

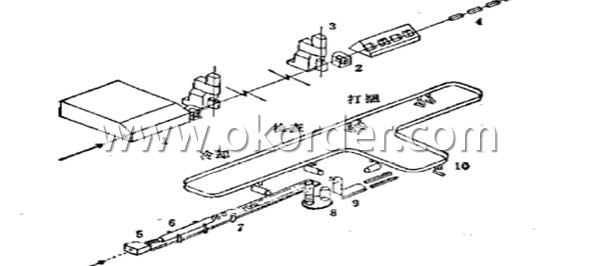

Production Process of Wire Rod SAE1008B:

1-Furnace 2-Roughing Mill 3-High-speed Finishing Mill 4-Water-cooled Device 5-Coiling Device

6-Cooling Device 7-Chain Conveyer 8-Spool Collecting Device 9-Spool Down Device 10-Hook Conveyer

Packaging & Delivery of Wire Rod SAE1008B:

Packaging Detail: products are packed in coil and then shipped by container or bulk vessel

Each coil weight: 2-3MT

Delivery Detail: within 45 days after received deposit or LC.

Label: to be specified by customer, generally, each bundle has 1-2 labels

Trade terms: CFR, CIF

Wire Rod in Container

Wire Rod in Bulk Vessel

Note:

1. Our products are produced according to national standard (GB), if not, supply according to national standards (GB) or agreement as customer required.

2. Other Grade and Standard carbon steel wire rod we can supply:

Grade: H08A, 30MnSi, 62B-82B

Standard: AISI, BS, JIS, DIN

The Minimum Order Quantity of these products is high, and need to be confirmed.

3. We can not only supply carbon steel wire rod; if you need anything about building materials, please contact us.

4. Please send us your detail specifications when inquire. We will reply to you as soon as possible. We sincerely hope we can establish a long stable business relationship.

- Q: What are the main factors influencing the choice of steel wire rod order warranty claims process?

- The main factors influencing the choice of steel wire rod order warranty claims process can vary depending on various aspects. Firstly, the quality of the steel wire rod plays a significant role in determining the warranty claims process. If the wire rod is of high quality and meets the required standards, then the warranty claims process may be less frequent and straightforward. On the other hand, if the wire rod has inherent flaws or defects, it is more likely to result in warranty claims, and the process may be more complex. Secondly, the terms and conditions of the warranty provided by the supplier or manufacturer can greatly influence the choice of the warranty claims process. The duration of the warranty, the coverage provided, and any limitations or exclusions can impact the decision-making process. If the warranty offers comprehensive coverage and is backed by a reputable supplier, it may instill confidence in the buyer, making them more inclined to choose that particular warranty claims process. Furthermore, the availability and efficiency of customer support and after-sales service are important factors in deciding the warranty claims process. A prompt and responsive customer support team can expedite the claims process, provide necessary guidance, and address any concerns or queries from the buyer. This level of support can significantly influence the choice of the warranty claims process, as it ensures a smoother and more satisfactory experience for the buyer. Additionally, the reputation and track record of the supplier or manufacturer can also impact the decision-making process. Buyers are more likely to choose a warranty claims process from a trusted and reliable supplier with a history of honoring their warranty obligations promptly and fairly. This factor can provide peace of mind to the buyer and increase their confidence in choosing a particular warranty claims process. Lastly, the cost and convenience of the warranty claims process can also influence the choice. If the process is cost-effective and convenient for the buyer, they may be more inclined to choose that particular warranty claims process. This can include factors such as the ease of filing a claim, the time taken for resolution, and any associated costs or deductibles. Overall, the main factors influencing the choice of steel wire rod order warranty claims process revolve around the quality of the product, the terms and conditions of the warranty, the availability of customer support, the reputation of the supplier, and the cost and convenience of the process.

- Q: Can steel wire rod be used in the production of springs?

- Yes, steel wire rod can be used in the production of springs. Steel wire rod is commonly used due to its high strength and durability, which are essential characteristics for springs that need to withstand repeated stress and maintain their shape over time.

- Q: What are the common forming techniques used for steel wire rod?

- The common forming techniques used for steel wire rod include drawing, rolling, and extrusion.

- Q: How is the surface roughness of steel wire rod measured?

- The surface roughness of steel wire rod is commonly measured using a device called a profilometer. This instrument scans the surface of the wire rod and provides measurements of the roughness parameters such as Ra (average roughness), Rz (maximum peak-to-valley height), and Rt (total roughness). These measurements help determine the quality and suitability of the wire rod for various applications.

- Q: How is steel wire rod used in the manufacturing of wire forms for aerospace applications?

- Steel wire rod is used in the manufacturing of wire forms for aerospace applications as it provides high strength and durability, making it suitable for critical components. The wire rod is first drawn through a series of dies to obtain the desired diameter and then undergoes various shaping processes such as bending, coiling, or twisting to create intricate wire forms. These wire forms are used in various aerospace applications such as aircraft seating, control systems, and structural components due to their ability to withstand high loads and maintain their shape even under extreme conditions.

- Q: What are the main components of steel wire rod?

- The main components of steel wire rod are iron, carbon, and other alloying elements such as manganese, silicon, and chromium.

- Q: How is steel wire rod used in the production of wire mesh for filtration?

- The production of wire mesh for filtration requires the use of steel wire rod, which is an indispensable component. This raw material is utilized to manufacture wire mesh, a widely used product in industries like mining, construction, and agriculture. To create wire mesh for filtration purposes, the steel wire rod undergoes a series of manufacturing processes. Initially, the wire rod is heated and then rolled into thin strands known as wire. These wires have a consistent diameter and a smooth surface, ensuring top-notch filtration quality. Subsequently, the wire is woven or welded to achieve the desired mesh pattern. The weaving process involves interlacing the wires above and below each other, resulting in a sturdy and long-lasting mesh structure. Alternatively, the wires can be welded at their intersections to create a more rigid mesh. The selection of steel wire rod for wire mesh production is based on its specific properties. Steel is renowned for its strength, durability, and resistance to corrosion, making it an excellent choice for demanding filtration applications. Additionally, the wire rod can undergo additional treatments to enhance its performance, such as applying coatings to improve resistance against abrasion or chemicals. Once the wire mesh is manufactured, it finds application in various filtration processes. Wire mesh filters are commonly employed to separate solids from liquids or gases, effectively eliminating impurities and contaminants. Moreover, they can be utilized as sieves or screens to classify or separate materials based on their size or shape. In conclusion, the utilization of steel wire rod is paramount in the production of wire mesh for filtration purposes. Through a series of manufacturing processes, wire mesh is created and extensively utilized in diverse filtration applications across various industries. The strength, durability, and corrosion resistance of steel make it an ideal choice for filtration needs that demand excellence.

- Q: How is the cleanliness of steel wire rod assessed?

- The cleanliness of steel wire rod is assessed through various methods and techniques to ensure high-quality standards. One common method used is visual inspection, where trained personnel thoroughly scan the surface of the wire rod for any visible defects such as scale, cracks, pits, or other surface irregularities that could affect its cleanliness. Another technique is magnetic particle testing, which involves placing the wire rod in a magnetic field and applying magnetic particles to the surface. Any discontinuities or defects in the material will cause the particles to be attracted and accumulate, making them visible under proper lighting conditions. Ultrasonic testing is also employed to assess the cleanliness of steel wire rod. This non-destructive testing method uses high-frequency sound waves to detect internal defects such as inclusions, voids, or other imperfections that are not visually apparent. Ultrasonic waves are transmitted through the wire rod, and any reflections or changes in the waves' pattern can indicate the presence of defects. Chemical analysis is another crucial aspect of assessing cleanliness. Samples of the wire rod are taken and subjected to chemical tests to determine the composition and impurity levels. This analysis can identify contaminants such as sulfur, phosphorus, or other elements that may affect the cleanliness of the steel. Overall, a combination of visual inspection, magnetic particle testing, ultrasonic testing, and chemical analysis is typically used to assess the cleanliness of steel wire rod. By implementing these methods, manufacturers can ensure that the wire rod meets the required cleanliness standards, guaranteeing its suitability for various applications.

- Q: How is steel wire rod used in the manufacturing of wire forms for security fencing?

- Steel wire rod is an essential component in the manufacturing of wire forms for security fencing. It serves as the main raw material for creating durable and strong wire fences. Firstly, steel wire rod is processed through a series of mechanical and chemical treatments to enhance its properties, such as strength, flexibility, and corrosion resistance. This ensures that the wire forms produced from it can withstand harsh weather conditions, physical impact, and attempts of breaching. Once the steel wire rod is prepared, it is then formed into various shapes and sizes to fit the specific requirements of security fencing. This can include straight wires, coils, or even intricate designs like barbed wire or razor wire, depending on the level of security desired. The wire forms are then assembled and connected to create the desired security fence structure. This can involve weaving, welding, or fastening the wire forms together using specialized tools and techniques. The strength and durability of the steel wire rod ensures that the fence will maintain its structural integrity and resist any attempts to cut, break, or tamper with it. Moreover, steel wire rod can also be galvanized or coated with protective layers to enhance its resistance to corrosion, rust, and other environmental factors. This further increases the lifespan of the security fence and reduces the need for frequent maintenance or replacement. In summary, steel wire rod plays a crucial role in the manufacturing of wire forms for security fencing. Its strength, durability, and resistance to corrosion make it an ideal material for creating robust and long-lasting fences that provide effective security measures.

- Q: What is the hardness range of steel wire rod?

- The hardness range of steel wire rod typically varies between 350 to 550 on the Brinell hardness scale.

Send your message to us

High quality wire rod 6.5mm-14mm SAE1008 and 1006

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords