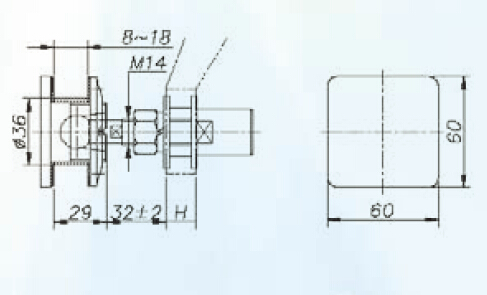

Square Shape Flat Cap Routel for Spider AT30

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 Piece/Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Product Name | Square Shape Flat Cap Routel for Spider AT30 |

Material | Stainless Steel 304/316. |

Finish | Natural |

Glass thickness | 8~18mm |

Bolt Size | M14 |

Max. axial bearing capacity | 4500N |

Max. Radial Bearing capacity | 2000N |

Adjustable angle | ±10 degree |

Min Order | 100piece/ pieces |

Packing | Inner Box + Carton Box |

Supply capacity | 100000 piece/ pieces per month |

Delivery time | 20~35 days after receipt of down payment |

Export market | Asia, America, Europe, Africa, markets. |

1. Reliable Supplier |

2. High Quality |

3. Standard Producing Technology |

4. Competitive Factory Price |

5. Fast Delivery |

Product Pictures:

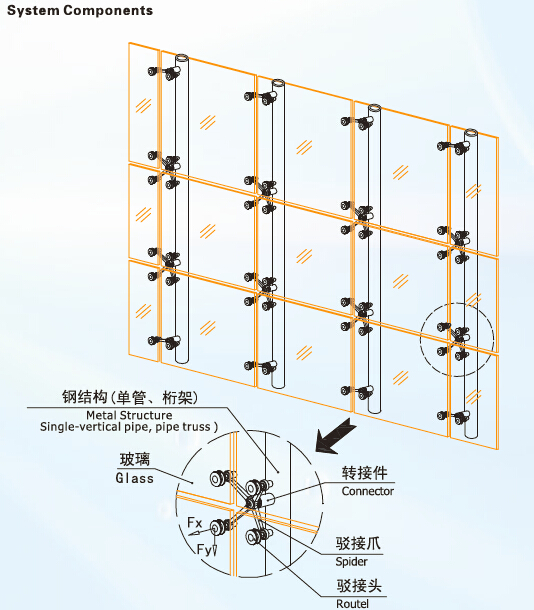

- Q: The installation method of the splicing jaws

- Steel beams and glass are ready to ensure that the location is not wrong, as well as glass holes, adapter and steel beam welding no problem. Put the claws on the transfer, engage in tight. Put the splice on the glass, engage in tight, do not forget the middle of the gasket. Then, the glass is mounted, the splice is connected with the splicing jaws, but do not twist too tightly, and then adjust the position and adjust the error. Finally, tighten, check the next to ensure safety. Ordinary is so loaded, of course, there are different styles, installation methods are different, but not difficult.

- Q: A set of curtain wall point of the stainless steel access to the claws, including what?

- Stainless steel access pawls generally include the shuttle paw and the access head, the model has 150 series, 160 series, 200 series, 220 series, 250 series, 300 series, divided into four claws, three claws, 90 degrees two claws, 180 degrees two claws , Long claws, short claws, from the material there are 202 material, 304 material, 316 material and so on! Some of the specific circumstances to be customized!

- Q: Who knows which factory is good? Recommended!

- Not bad money to buy hard, the best brand.

- Q: Glass curtain wall glass installation process requirements which out

- The stainless steel splicing pawl-type curtain wall fittings are composed of splice joints, splicing claws, adapter parts and so on. The splicing jaws are mainly used as supporting link joints and pass the load to the fixed supporting structure system, which is connected with the glass curtain wall An important accessory. With the impact of the curtain wall industry, in order to achieve the best effect of the use of stainless steel splicing claws, construction details are essential, and today to introduce some of the details of the construction of the splicing claws and the need to pay attention to the problem.

- Q: Would like to ask about the two ways of fixing the glass curtain wall glass

- 1. The glass panel is fixed to the support structure by a glass rib structure. The load of the panel is transmitted through the glass rib structure to the support structure and the main structure. 2. Splicing claws are divided into X-shaped, H-shaped, mountain-shaped, etc .; according to the surface treatment is divided into mirror light, matte, fluorocarbon spray; by material is divided into stainless steel, aluminum and so on. Glass curtain wall auxiliary tool this Rieter electric basket

- Q: What are the accessories of the point-supported glass curtain wall?

- Point-type glass curtain wall accessories are stainless steel curtain wall adapter, split joints, split claws, glass clip, handrail pieces, rain canopy accessories, support rods, rods, cable, stainless steel mini cable and so on.

- Q: How is the glass curtain wall attached to the steel frame fixed on the steel frame

- Steel structure point curtain wall cylindrical adapter seat welded to the steel structure, the splicing claw screw to the adapter seat, the joint and then fixed to the splicing claw

- Q: What is the reason for rusting the claws?

- Stainless steel is the surface of the formation of a very thin layer of thin and strong and stable stable chromium oxide film (protective film), to prevent oxygen atoms continue to infiltrate, continue to oxidize, and get the ability to resist corrosion. There is some reason, this film is constantly destroyed, the air or liquid and oxygen atoms will continue to infiltrate or metal iron atoms continue to precipitate out to form loose iron oxide, metal surface will be constantly Rust.

- Q: What are the skeleton of the glass curtain wall system

- Pendant glass curtain wall This is the use of four-jaw stainless steel pendant with the column welding, pendant of each claw with a glass of a hole connected to the two pendant at the same time with four glass connected, or a piece of glass fixed on the four pendant. Four holes drill holes.

- Q: Can the bike rear pendant be affixed to the car glass?

- Point glass curtain wall to be fully considered before installation: connecting stainless steel splicing jaws of the steel structure during the construction of the size of the deviation, to re-line positioning. When confronting the glass, consider the pore size of the glass mounting hole.

Send your message to us

Square Shape Flat Cap Routel for Spider AT30

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 Piece/Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches