Spline shaft OEM hobbing,shaving,grinding for machine OEM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

| Material: | Steel,as requirements | Processing: | Forging | Pressure Angle: | 20 |

| Place of Origin: | Zhejiang China (Mainland) | technology of material: | forging | technology of machining: | hobbing,shaving,grinding |

| heatreatment: | nitriding,carburization | OEM: | is acceptable |

Packaging & Delivery

| Packaging Detail: | packed in carton |

| Delivery Detail: | 70days |

Specifications

1.produce as drawings

2.material will be as requirements

3.strictly quality control

4.OEM is acceptable

Products information:

1. suitable for many sorts of transmission system, such as agriculture tractor, wind power, truck and other industry zone.

2. material and precision can be as requirements.

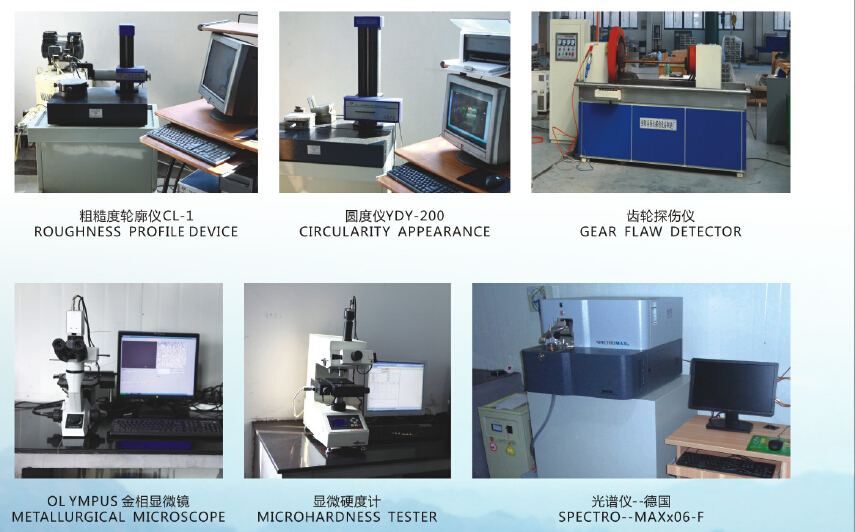

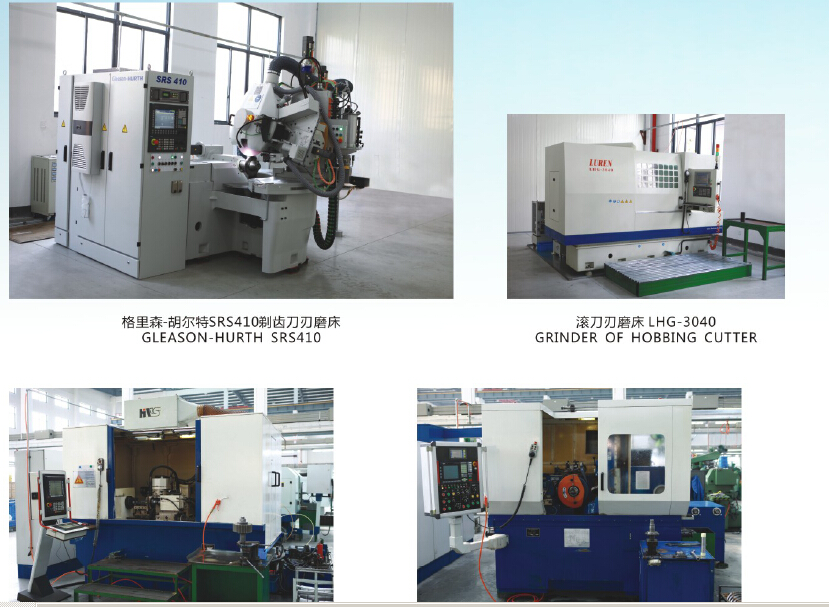

3. we have complete gear machining equipments: gear hobbing machine, shaving machine, gear shaper, gear grinding machine, and our own heat treatment center. all of the production procedure are strictly controlled by ourselves, no cooperation procession, so we can sure the final products to meet your requirements.

4.each processing, strictly quality control

5.certificate: ISO9001, ISO/TS16949

- Q: In the processing of gear ring down end angle is cumbersome, requires a lot of hard work, Master Wang, senior, Ariadne, how fast, mass production? What kind of chamfer do you use? What knife do you use? We take out sun drying, learn from each other, study together, improve efficiency ~ ~ ~!

- Chamfering can be made in Tianjin by chamfering machines, which can be adjusted according to different products. Chamfering is the burr of the chamfering surface. Corrected to a small edge

- Q: Why a screw worm gear ring interference fit to cast iron core wheel side bias

- General assembly of worm wheel core steel or cast iron, bronze and crown, the hardness is much higher than the latter.

- Q: What are the factors that affect the radial runout of gear ring?

- Thus resulting in bearings wear, deformation of the top of the tooth, wear gap. In the process of machining, the shaft has concentricity, roundness, pulsation and other tolerance factors.

- Q: Which car axle manufacturers buy ABS gear ring?

- First, the application of ABS, the world's first anti lock braking system ABS (Ant-ilock Brake System), was introduced in 1950. It was first used in the aviation field of the aircraft, and in 1968 began to study in the automotive applications. In 70s, disc brakes were introduced to the front wheels or front and rear wheels of new cars produced in Europe and the United States, prompting the application of ABS in automobiles.

- Q: The radial runout of the gear ring affects the accuracy of the gear drive, so the gear is to be checked on the shaft and the runout of the end face.

- Therefore, after the gear is mounted on the shaft, check (A radial runout) and runout of the end face

- Q: Ring gear material 50Mn heat treatment, conditioning is shrink or rise?

- Specific methods in the process of heating and cooling of heat treatment. It's a synthetic phenomenon. The final shrinkage is determined by the specific heat treatment process parameters and the quenching medium. Due to the stress, the hole may be swollen.

- Q: What is the clearance between the sensor and the gear ring?

- There are many kinds of sensors, such as Holzer, photoelectric and so on

- Q: PROE simulation, how to make the inner ring does not move, the planet wheel around the rotation

- The new assembly will be inserted into the inner ring, fixed, and then put the planet rack assembly, which can be rotated, and then insert the planet wheel, set up a pair of connections.

- Q: How does the ring ring when the car turns the key?

- Hello, that's your ring gear. It won't make any noise when you hit the gear ring

- Q: Where is the axle ring in the car?

- Hello, ABS signal acquisition, generally on the outside of the cage, and I hope to help you

Send your message to us

Spline shaft OEM hobbing,shaving,grinding for machine OEM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords